Acrylic laminating creates a durable, protective layer by bonding a clear acrylic sheet onto a surface, enhancing scratch resistance and clarity without altering the base material. Acrylic coating involves applying a liquid acrylic layer that dries to form a smooth, glossy finish, improving surface protection but offering less thickness than laminates. Choosing between laminating and coating depends on the desired level of durability, optical clarity, and application method for acrylic pet products.

Table of Comparison

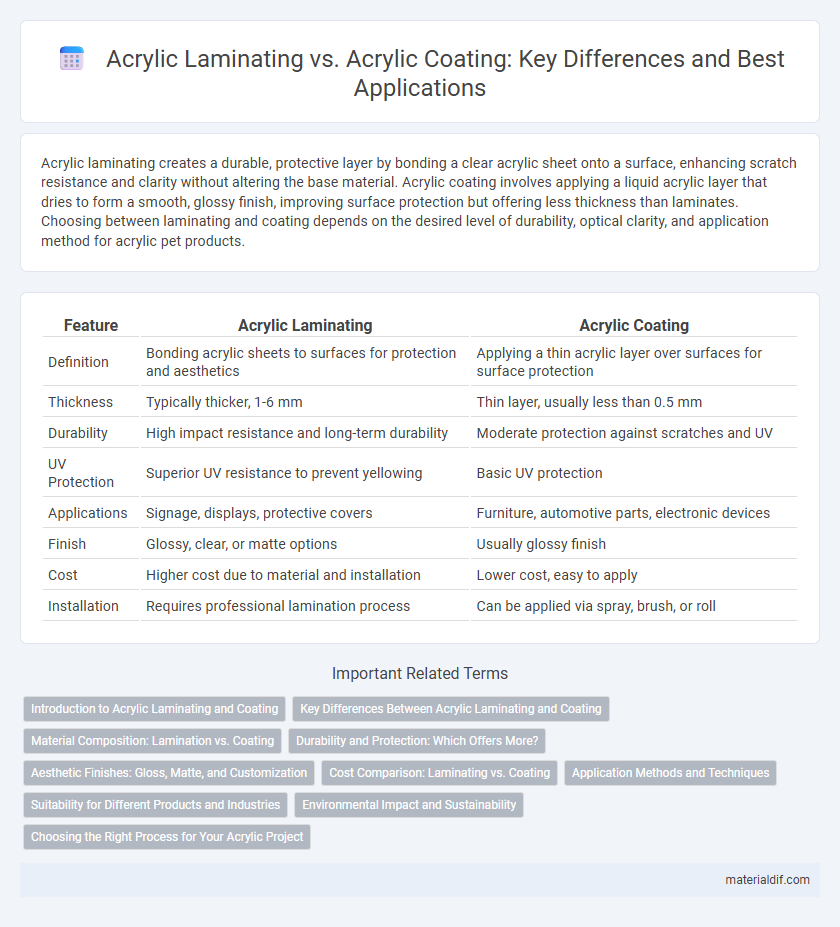

| Feature | Acrylic Laminating | Acrylic Coating |

|---|---|---|

| Definition | Bonding acrylic sheets to surfaces for protection and aesthetics | Applying a thin acrylic layer over surfaces for surface protection |

| Thickness | Typically thicker, 1-6 mm | Thin layer, usually less than 0.5 mm |

| Durability | High impact resistance and long-term durability | Moderate protection against scratches and UV |

| UV Protection | Superior UV resistance to prevent yellowing | Basic UV protection |

| Applications | Signage, displays, protective covers | Furniture, automotive parts, electronic devices |

| Finish | Glossy, clear, or matte options | Usually glossy finish |

| Cost | Higher cost due to material and installation | Lower cost, easy to apply |

| Installation | Requires professional lamination process | Can be applied via spray, brush, or roll |

Introduction to Acrylic Laminating and Coating

Acrylic laminating involves bonding a thin acrylic film onto surfaces to enhance durability, UV resistance, and aesthetic appeal, commonly used in signage and display industries. Acrylic coating, on the other hand, refers to applying a liquid acrylic layer directly onto substrates to provide a protective, glossy finish that improves scratch resistance and weatherability. Both techniques leverage acrylic's transparency and toughness but differ in application methods and performance benefits tailored to specific industrial needs.

Key Differences Between Acrylic Laminating and Coating

Acrylic laminating involves bonding a thin acrylic film onto a surface to enhance durability, UV resistance, and aesthetic appeal, while acrylic coating refers to applying a liquid acrylic layer directly onto a substrate for protection and gloss finish. Laminating provides a thicker, more impact-resistant barrier compared to coating, which offers a lighter, more flexible protective layer that can be easily reapplied or repaired. Key differences include the application method, thickness, durability, and the resulting surface texture and longevity.

Material Composition: Lamination vs. Coating

Acrylic laminating involves bonding multiple acrylic sheets or layers with adhesives, resulting in increased thickness and enhanced durability, while acrylic coating applies a thin layer of polymer resin directly onto a substrate for surface protection and improved aesthetics. Laminates typically consist of solid acrylic layers fused together, offering structural reinforcement, whereas coatings are comprised of liquid acrylic formulations that cure to form a protective film. The choice between lamination and coating depends on the desired mechanical strength and surface finish, with lamination providing robust physical properties and coating delivering chemical resistance and clarity.

Durability and Protection: Which Offers More?

Acrylic laminating provides superior durability through a thick protective layer that resists scratches, moisture, and UV damage, making it ideal for high-traffic or outdoor applications. Acrylic coating offers a thinner, flexible surface protection that enhances gloss and resists minor abrasions but may wear down faster under heavy use. For long-term protection and strength, acrylic laminating outperforms acrylic coating by creating a more robust barrier against environmental factors and physical impact.

Aesthetic Finishes: Gloss, Matte, and Customization

Acrylic laminating offers a durable, high-gloss finish that enhances color vibrancy and provides strong protection against scratches and UV damage, ideal for premium aesthetic applications. Acrylic coating allows for greater versatility with options like matte, satin, and customizable textures, giving designers control over surface sheen and tactile experience. Both methods enable tailored aesthetic finishes, but laminating excels in depth and clarity, while coating prioritizes surface customization and versatile visual effects.

Cost Comparison: Laminating vs. Coating

Acrylic laminating typically incurs higher upfront costs due to the additional materials and labor involved, whereas acrylic coating offers a more budget-friendly solution with simpler application processes. Cost efficiency in acrylic coating makes it suitable for large-scale projects requiring broad protection without substantial material expenses. Laminating, while more expensive, provides enhanced durability and resistance, justifying its use in premium applications where long-term performance outweighs initial costs.

Application Methods and Techniques

Acrylic laminating involves bonding multiple layers of acrylic sheets using heat and pressure to create a durable, impact-resistant surface ideal for automotive, signage, and protective barriers. Acrylic coating applies a liquid acrylic polymer onto surfaces through spraying or brushing, providing UV resistance and enhanced gloss suitable for furniture, flooring, and artwork protection. Both techniques require precise control of temperature and curing times to ensure optimal adhesion and finish quality.

Suitability for Different Products and Industries

Acrylic laminating offers superior durability and impact resistance, making it ideal for protective coverings in automotive, electronics, and signage industries. Acrylic coating provides a thinner, more cost-effective finish suitable for furniture, packaging, and decorative surfaces requiring enhanced gloss and UV protection. Both processes enhance product longevity, but laminating is preferred for heavy-duty applications while coating suits lightweight, aesthetic-focused uses.

Environmental Impact and Sustainability

Acrylic laminating offers enhanced durability and UV resistance, reducing the need for frequent replacements and lowering overall environmental waste. Acrylic coating, while providing a protective layer, typically requires more frequent reapplication, leading to increased solvent emissions and higher resource consumption. Choosing acrylic laminating supports sustainability goals by extending product lifespan and minimizing ecological footprint compared to traditional acrylic coatings.

Choosing the Right Process for Your Acrylic Project

Acrylic laminating involves bonding a protective acrylic film to a substrate, enhancing durability and UV resistance, making it ideal for projects requiring strong surface protection and enhanced aesthetics. Acrylic coating applies a liquid acrylic layer directly onto materials, providing a smooth, glossy finish with excellent scratch resistance and weatherability, suitable for applications needing a seamless and uniform surface. Selecting between laminating and coating depends on project requirements such as exposure conditions, desired finish, and long-term durability, with lamination favored for heavy-duty protection and coating preferred for sleek, resilient surfaces.

Acrylic Laminating vs Acrylic Coating Infographic

materialdif.com

materialdif.com