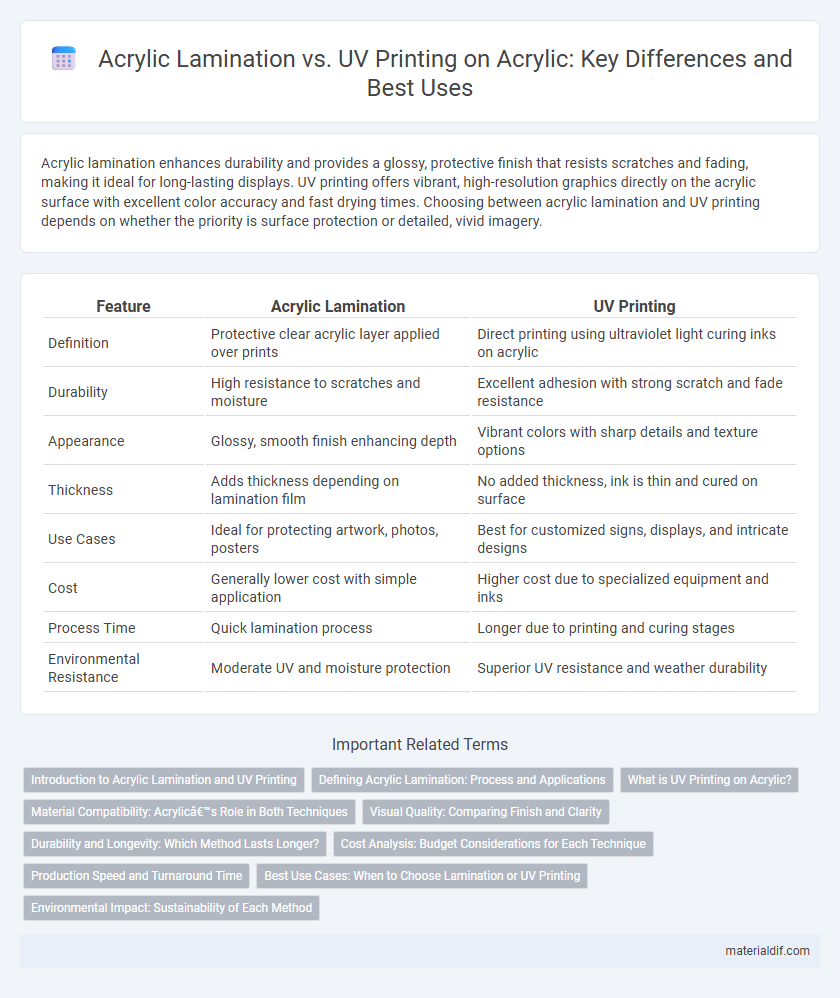

Acrylic lamination enhances durability and provides a glossy, protective finish that resists scratches and fading, making it ideal for long-lasting displays. UV printing offers vibrant, high-resolution graphics directly on the acrylic surface with excellent color accuracy and fast drying times. Choosing between acrylic lamination and UV printing depends on whether the priority is surface protection or detailed, vivid imagery.

Table of Comparison

| Feature | Acrylic Lamination | UV Printing |

|---|---|---|

| Definition | Protective clear acrylic layer applied over prints | Direct printing using ultraviolet light curing inks on acrylic |

| Durability | High resistance to scratches and moisture | Excellent adhesion with strong scratch and fade resistance |

| Appearance | Glossy, smooth finish enhancing depth | Vibrant colors with sharp details and texture options |

| Thickness | Adds thickness depending on lamination film | No added thickness, ink is thin and cured on surface |

| Use Cases | Ideal for protecting artwork, photos, posters | Best for customized signs, displays, and intricate designs |

| Cost | Generally lower cost with simple application | Higher cost due to specialized equipment and inks |

| Process Time | Quick lamination process | Longer due to printing and curing stages |

| Environmental Resistance | Moderate UV and moisture protection | Superior UV resistance and weather durability |

Introduction to Acrylic Lamination and UV Printing

Acrylic lamination involves applying a protective acrylic film over surfaces to enhance durability, resistance to scratches, and clarity, making it ideal for signage and displays. UV printing uses ultraviolet light to cure ink directly onto substrates, offering vibrant colors, precise details, and fast drying on acrylic materials. Both technologies serve distinct purposes: lamination protects and enhances physical attributes, while UV printing delivers high-resolution customization on acrylic surfaces.

Defining Acrylic Lamination: Process and Applications

Acrylic lamination involves bonding a clear acrylic sheet to a surface using pressure-sensitive adhesive or heat, enhancing durability and providing a glossy, protective finish. This process is widely used in signage, displays, and photo preservation to safeguard printed materials from UV rays, moisture, and scratches. Unlike UV printing, which directly prints images using ultraviolet light curing, acrylic lamination primarily serves as a protective layer rather than a printing method.

What is UV Printing on Acrylic?

UV printing on acrylic is a digital printing technique that uses ultraviolet light to cure or dry the ink as it is printed directly onto the acrylic surface, producing vibrant and durable results. This method allows for high-resolution images with sharp details and is resistant to fading, scratches, and weather exposure. UV printing eliminates the need for lamination by creating a protective layer within the ink itself, making it ideal for signage, displays, and decorative applications.

Material Compatibility: Acrylic’s Role in Both Techniques

Acrylic serves as a highly versatile substrate in both acrylic lamination and UV printing, offering excellent clarity and durability that enhance print quality. Its smooth, non-porous surface ensures strong adhesion of lamination films while enabling UV inks to cure rapidly and bond effectively, resulting in vibrant, long-lasting images. Compatibility with acrylic in these processes maximizes resistance to environmental factors such as moisture and UV exposure, preserving the visual appeal and structural integrity of printed materials.

Visual Quality: Comparing Finish and Clarity

Acrylic lamination offers a smooth, glossy finish that enhances color vibrancy and provides superior protection against scratches and UV damage. UV printing directly on acrylic delivers sharp, high-resolution images with excellent clarity and precise detail, allowing for intricate designs and gradients. While lamination adds depth and a polished surface, UV printing excels in crispness and durability without compromising the acrylic's natural transparency.

Durability and Longevity: Which Method Lasts Longer?

Acrylic lamination offers enhanced durability by providing a protective layer that resists scratches, UV rays, and moisture, significantly extending the lifespan of the acrylic surface. UV printing directly bonds ink to the acrylic, resulting in vibrant colors but a slightly lower resistance to abrasion and environmental damage compared to lamination. For long-term applications requiring maximum protection and longevity, acrylic lamination generally outperforms UV printing in preserving appearance and structural integrity.

Cost Analysis: Budget Considerations for Each Technique

Acrylic lamination generally incurs lower upfront costs due to simpler equipment and materials, making it ideal for budget-conscious projects requiring protective finishes. UV printing involves higher initial investment and operational expenses but offers detailed, vibrant graphics directly on acrylic surfaces, suitable for premium applications. Evaluating project scale and desired visual quality helps determine the most cost-effective method between acrylic lamination and UV printing.

Production Speed and Turnaround Time

Acrylic lamination offers faster production speed due to its straightforward application process and minimal curing requirements, enabling quicker turnaround times for high-volume orders. UV printing, while providing superior detail and color vibrancy, requires longer curing periods and meticulous setup, which can extend production timelines. Choosing between acrylic lamination and UV printing depends on prioritizing rapid delivery versus enhanced visual quality in acrylic signage and displays.

Best Use Cases: When to Choose Lamination or UV Printing

Acrylic lamination is ideal for enhancing durability and scratch resistance on surfaces exposed to frequent handling or outdoor conditions, making it perfect for protective signage and display cases. UV printing excels in producing vibrant, high-resolution images directly on acrylic sheets, suitable for detailed graphics and customized artwork in indoor decorative applications. Choose lamination for long-lasting protection and UV printing for rich, crisp visuals with intricate design elements.

Environmental Impact: Sustainability of Each Method

Acrylic lamination generally uses adhesive films and solvents that can release volatile organic compounds (VOCs), raising environmental concerns due to non-biodegradable waste and energy-intensive production processes. UV printing involves curing inks with ultraviolet light, resulting in minimal VOC emissions and reduced solvent use, making it a more sustainable choice with less environmental footprint. Both methods benefit from recycling initiatives, but UV printing's lower chemical waste and energy efficiency give it a stronger advantage in eco-friendly acrylic decoration.

Acrylic Lamination vs UV Printing Infographic

materialdif.com

materialdif.com