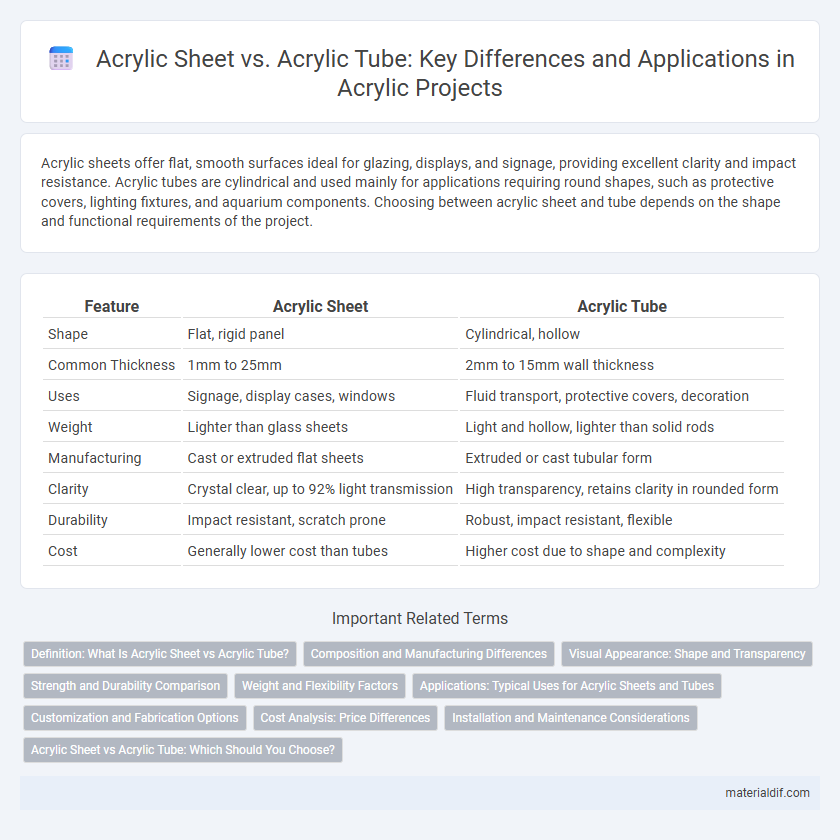

Acrylic sheets offer flat, smooth surfaces ideal for glazing, displays, and signage, providing excellent clarity and impact resistance. Acrylic tubes are cylindrical and used mainly for applications requiring round shapes, such as protective covers, lighting fixtures, and aquarium components. Choosing between acrylic sheet and tube depends on the shape and functional requirements of the project.

Table of Comparison

| Feature | Acrylic Sheet | Acrylic Tube |

|---|---|---|

| Shape | Flat, rigid panel | Cylindrical, hollow |

| Common Thickness | 1mm to 25mm | 2mm to 15mm wall thickness |

| Uses | Signage, display cases, windows | Fluid transport, protective covers, decoration |

| Weight | Lighter than glass sheets | Light and hollow, lighter than solid rods |

| Manufacturing | Cast or extruded flat sheets | Extruded or cast tubular form |

| Clarity | Crystal clear, up to 92% light transmission | High transparency, retains clarity in rounded form |

| Durability | Impact resistant, scratch prone | Robust, impact resistant, flexible |

| Cost | Generally lower cost than tubes | Higher cost due to shape and complexity |

Definition: What Is Acrylic Sheet vs Acrylic Tube?

Acrylic sheet is a flat, rigid panel made from polymethyl methacrylate (PMMA) used for glazing, signage, and display applications due to its clarity and impact resistance. Acrylic tube, also made from PMMA, is a hollow cylindrical form designed for applications requiring a lightweight, transparent, and durable structure, such as aquariums, light fixtures, and protective covers. Both materials offer excellent UV resistance and can be customized in thickness, diameter, and color to suit various industrial and decorative purposes.

Composition and Manufacturing Differences

Acrylic sheets and acrylic tubes share the same primary composition of polymethyl methacrylate (PMMA), offering clarity, UV resistance, and weatherability advantages. The manufacturing of acrylic sheets typically involves a continuous casting or extrusion process to create flat, uniform panels, while acrylic tubes are produced through extrusion or casting methods that form the material into hollow cylindrical shapes. Variations in cooling rates and mold designs during production result in differences in mechanical properties and surface finishes between sheets and tubes.

Visual Appearance: Shape and Transparency

Acrylic sheets offer a flat, uniform surface with crystal-clear transparency, ideal for applications requiring wide, smooth panels and maximum light transmission. Acrylic tubes provide a cylindrical shape with consistent clarity, enhancing aesthetic appeal in rounded designs and allowing light to pass through evenly around the curved surface. Both forms maintain high optical clarity but differ significantly in shape versatility and visual dimension impact.

Strength and Durability Comparison

Acrylic sheets offer exceptional impact resistance and rigidity, making them ideal for applications requiring flat, durable surfaces. Acrylic tubes provide superior structural strength due to their cylindrical shape, which evenly distributes stress and enhances load-bearing capacity. Both forms exhibit high weather resistance and UV stability, but tubes generally outperform sheets in durability under compressive forces.

Weight and Flexibility Factors

Acrylic sheets typically weigh less per square foot than acrylic tubes of similar dimensions due to their flat, uniform shape, making them ideal for lightweight applications. Acrylic tubes offer greater flexibility and impact resistance because their cylindrical form distributes stress more evenly, which helps prevent cracking under pressure. When selecting between acrylic sheet and tube, consider the weight requirements and needed flexibility for the specific project to optimize performance and durability.

Applications: Typical Uses for Acrylic Sheets and Tubes

Acrylic sheets are commonly used for signage, displays, windows, and protective barriers due to their flat, rigid surface and excellent optical clarity. Acrylic tubes find applications in lighting fixtures, aquarium tanks, and medical devices where a cylindrical shape and structural strength are required. Both materials offer versatility in construction, but sheets excel in flat panel applications while tubes are preferred for rounded or hollow structures.

Customization and Fabrication Options

Acrylic sheets offer extensive customization in thickness, color, and surface finish, making them ideal for flat panel applications and easy to fabricate through cutting, drilling, and bending. Acrylic tubes provide unique fabrication options suited for cylindrical designs, with customization available in diameter, wall thickness, and length to meet specific structural or decorative needs. Both forms accommodate diverse finishing techniques, but acrylic sheets generally allow greater versatility in shaping and surface treatment for complex projects.

Cost Analysis: Price Differences

Acrylic sheets generally offer a lower cost per square foot compared to acrylic tubes due to simpler manufacturing processes and less material usage. Acrylic tubes often have higher prices because of added complexities in extrusion and shaping, as well as the thicker walls required for structural integrity. Businesses typically choose sheets for large surface applications to optimize budget, while tubes are selected for projects needing cylindrical strength despite the higher price.

Installation and Maintenance Considerations

Acrylic sheets offer flat, smooth surfaces ideal for easy cutting and simple installation using adhesives or mechanical fasteners, requiring minimal maintenance with occasional cleaning using mild soap and water. Acrylic tubes, designed for cylindrical applications, often demand specialized fittings and careful handling during installation to avoid cracks or stress fractures, while maintenance focuses on preventing surface scratches and ensuring clarity through gentle cleaning methods. Both materials benefit from UV-resistant coatings to extend durability and reduce yellowing over time in outdoor environments.

Acrylic Sheet vs Acrylic Tube: Which Should You Choose?

Acrylic sheets offer flat, versatile surfaces ideal for signage, displays, and protective barriers, while acrylic tubes provide cylindrical shapes suited for lighting fixtures, fluid transport, and decorative applications. The choice between acrylic sheet and tube depends on the project's dimensional and structural requirements, with sheets preferred for broad, flat coverage and tubes favored for hollow or round structures. Consider factors such as transparency, impact resistance, and fabrication methods to determine the best acrylic form for your specific needs.

Acrylic Sheet vs Acrylic Tube Infographic

materialdif.com

materialdif.com