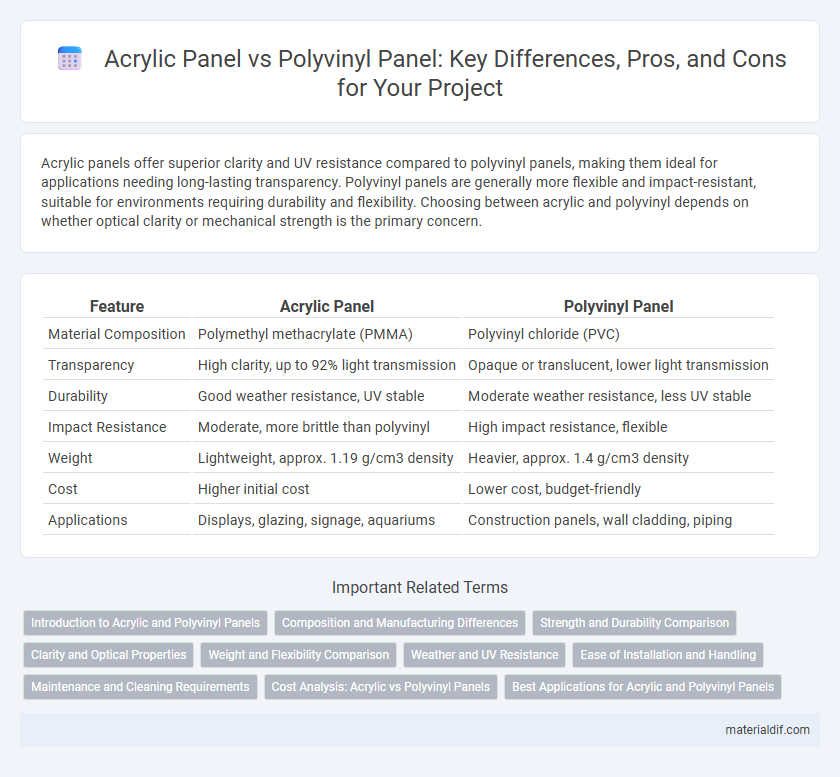

Acrylic panels offer superior clarity and UV resistance compared to polyvinyl panels, making them ideal for applications needing long-lasting transparency. Polyvinyl panels are generally more flexible and impact-resistant, suitable for environments requiring durability and flexibility. Choosing between acrylic and polyvinyl depends on whether optical clarity or mechanical strength is the primary concern.

Table of Comparison

| Feature | Acrylic Panel | Polyvinyl Panel |

|---|---|---|

| Material Composition | Polymethyl methacrylate (PMMA) | Polyvinyl chloride (PVC) |

| Transparency | High clarity, up to 92% light transmission | Opaque or translucent, lower light transmission |

| Durability | Good weather resistance, UV stable | Moderate weather resistance, less UV stable |

| Impact Resistance | Moderate, more brittle than polyvinyl | High impact resistance, flexible |

| Weight | Lightweight, approx. 1.19 g/cm3 density | Heavier, approx. 1.4 g/cm3 density |

| Cost | Higher initial cost | Lower cost, budget-friendly |

| Applications | Displays, glazing, signage, aquariums | Construction panels, wall cladding, piping |

Introduction to Acrylic and Polyvinyl Panels

Acrylic panels, known for their clarity, UV resistance, and impact strength, are commonly used in applications requiring transparency and durability, such as signage and protective barriers. Polyvinyl panels, typically made from polyvinyl chloride (PVC), offer excellent chemical resistance, flame retardancy, and weatherability, making them suitable for construction and industrial uses. Both materials provide versatile solutions, but acrylic panels excel in optical quality while polyvinyl panels prioritize robustness and cost-effectiveness.

Composition and Manufacturing Differences

Acrylic panels are primarily made from polymethyl methacrylate (PMMA), a transparent thermoplastic synthesized through polymerization of methyl methacrylate monomers, resulting in high optical clarity and weather resistance. Polyvinyl panels are composed mainly of polyvinyl chloride (PVC), a synthetic plastic polymer derived from vinyl chloride monomers, noted for its rigidity and chemical resistance but lower transparency. Manufacturing acrylic panels typically involves casting or extrusion processes that produce smooth, clear sheets, whereas polyvinyl panels are often fabricated by calendaring or injection molding, which can affect surface finish and transparency.

Strength and Durability Comparison

Acrylic panels exhibit superior impact resistance and tensile strength compared to polyvinyl panels, making them ideal for applications requiring long-lasting durability. Acrylic's resistance to UV radiation and weathering prevents yellowing and brittleness, maintaining clarity and structural integrity over time. Polyvinyl panels tend to be more prone to cracking and discoloration under prolonged environmental stress, reducing their lifespan and overall performance.

Clarity and Optical Properties

Acrylic panels offer superior clarity with light transmittance up to 92%, providing a crystal-clear, glass-like appearance unmatched by polyvinyl panels. Polyvinyl panels typically have lower optical clarity and tend to yellow over time when exposed to UV light, reducing transparency and aesthetic appeal. The enhanced optical properties of acrylic make it the preferred choice for applications requiring high visibility and long-lasting clarity.

Weight and Flexibility Comparison

Acrylic panels typically weigh around 50% less than polyvinyl panels, making them a lighter choice for various applications. In terms of flexibility, acrylic offers moderate rigidity but remains more prone to cracking under stress, whereas polyvinyl panels exhibit superior flexibility and impact resistance. This difference in weight and flexibility influences their suitability for installations requiring lightweight durability or enhanced bendability.

Weather and UV Resistance

Acrylic panels exhibit superior weather resistance and UV stability compared to polyvinyl panels, maintaining clarity and structural integrity under prolonged sun exposure and harsh environmental conditions. Polyvinyl panels tend to yellow and degrade faster due to limited UV protection, reducing their lifespan and aesthetic appeal. For outdoor applications requiring long-term durability and resistance to fading, acrylic panels are the preferred choice.

Ease of Installation and Handling

Acrylic panels offer superior ease of installation due to their lightweight nature and excellent rigidity, reducing the risk of cracking or breaking during handling. Unlike polyvinyl panels, acrylic's smooth surface allows for cleaner cuts and smoother finishes, making it ideal for precision applications. Its resistance to warping and scratching further enhances durability during installation and everyday use.

Maintenance and Cleaning Requirements

Acrylic panels require gentle cleaning with non-abrasive, mild soap solutions and soft cloths to prevent scratches and maintain clarity, while polyvinyl panels tolerate harsher chemical cleaners and more rigorous scrubbing without degrading. Acrylic's susceptibility to chemical damage necessitates avoiding solvents like ammonia or alcohol-based cleaners, whereas polyvinyl's chemical resistance allows for greater flexibility in maintenance products. Regular dusting and prompt removal of contaminants extend the lifespan of acrylic panels, whereas polyvinyl panels offer easier upkeep in high-traffic or industrial environments due to their tougher surface resilience.

Cost Analysis: Acrylic vs Polyvinyl Panels

Acrylic panels generally cost more than polyvinyl panels, with prices typically ranging from $20 to $30 per square foot compared to polyvinyl's $10 to $15 per square foot. Acrylic offers superior clarity and UV resistance, justifying its higher initial investment in applications demanding durability and aesthetics. Polyvinyl panels provide a budget-friendly alternative but may require more frequent replacement due to lower weather resistance and potential yellowing over time.

Best Applications for Acrylic and Polyvinyl Panels

Acrylic panels excel in applications requiring high optical clarity and UV resistance, making them ideal for signage, display cases, and protective barriers. Polyvinyl panels offer superior chemical resistance and impact durability, suited for industrial settings, chemical processing equipment, and construction where robustness is essential. Both materials provide versatile solutions, but acrylic is preferred for aesthetics and light transmission, while polyvinyl is favored for heavy-duty and corrosive environments.

Acrylic Panel vs Polyvinyl Panel Infographic

materialdif.com

materialdif.com