Acrylic casting involves pouring liquid acrylic into molds, producing parts with excellent optical clarity and superior chemical resistance, ideal for customized or small-batch applications. Acrylic injection molding uses heated acrylic pellets injected into precise molds, offering faster production rates and consistent dimensional accuracy suited for high-volume manufacturing. The choice between casting and injection molding depends on factors such as production scale, design complexity, and required material properties.

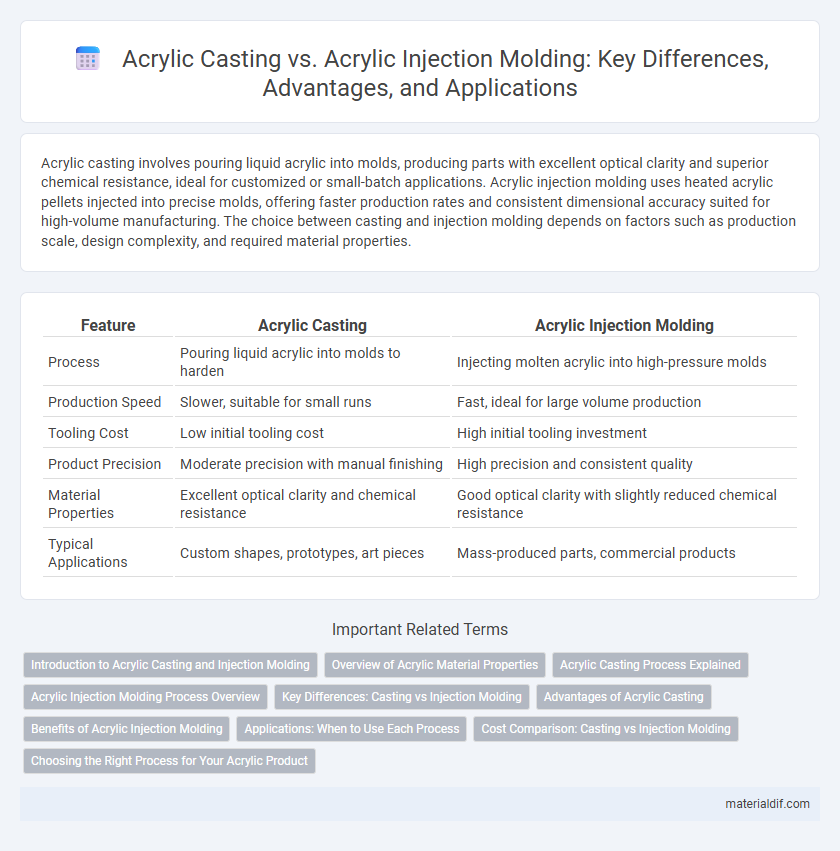

Table of Comparison

| Feature | Acrylic Casting | Acrylic Injection Molding |

|---|---|---|

| Process | Pouring liquid acrylic into molds to harden | Injecting molten acrylic into high-pressure molds |

| Production Speed | Slower, suitable for small runs | Fast, ideal for large volume production |

| Tooling Cost | Low initial tooling cost | High initial tooling investment |

| Product Precision | Moderate precision with manual finishing | High precision and consistent quality |

| Material Properties | Excellent optical clarity and chemical resistance | Good optical clarity with slightly reduced chemical resistance |

| Typical Applications | Custom shapes, prototypes, art pieces | Mass-produced parts, commercial products |

Introduction to Acrylic Casting and Injection Molding

Acrylic casting involves pouring liquid acrylic monomer into molds where it polymerizes into a solid form, ideal for creating large, clear, and custom-shaped parts with excellent optical clarity. Injection molding of acrylic uses high-pressure injection of molten acrylic resin into precision molds, enabling mass production of complex, detailed components with consistent quality and reduced cycle times. Both processes harness polymethyl methacrylate (PMMA) properties but differ significantly in production scale, detail resolution, and application suitability.

Overview of Acrylic Material Properties

Acrylic exhibits excellent optical clarity, high impact resistance, and superior weatherability, making it ideal for various manufacturing processes. Acrylic casting allows for thicker, custom shapes with enhanced stress resistance and optical purity, while acrylic injection molding suits high-volume production with precise dimensional control and faster cycle times. Both methods leverage acrylic's lightweight nature and UV resistance but differ in cost-effectiveness and mechanical property consistency for specific applications.

Acrylic Casting Process Explained

Acrylic casting involves pouring liquid monomer into a mold where it polymerizes into a solid form, allowing for complex shapes and high optical clarity. This process enables customization with precise detailing and better stress distribution compared to injection molding. Acrylic casting is ideal for small production runs and artistic applications due to its superior finish and less material waste.

Acrylic Injection Molding Process Overview

Acrylic injection molding involves melting acrylic resin pellets and injecting the molten material into a precision-machined mold cavity using high pressure, resulting in rapid cooling and solidification. This process enables the production of complex, high-precision parts with excellent surface finish and dimensional accuracy, suitable for large-volume manufacturing. Key parameters include injection pressure, mold temperature, and cooling time, all critical to achieving optimal mechanical properties and minimizing defects such as warping or residual stress.

Key Differences: Casting vs Injection Molding

Acrylic casting involves pouring liquid monomer into a mold where it polymerizes into solid form, allowing for larger, thicker, and more intricate shapes with superior optical clarity and minimal internal stress. Injection molding uses melted acrylic pellets injected under high pressure into a mold, enabling high-volume production with faster cycle times and consistent part dimensions but often resulting in slightly lower clarity and potential internal stress. Key differences lie in production speed, part complexity, optical quality, and suitability for either prototyping or mass manufacturing.

Advantages of Acrylic Casting

Acrylic casting offers superior optical clarity and is ideal for producing complex shapes with high precision and smooth finishes, outperforming injection molding in detail and quality. The casting process allows for customization in small to medium production runs with lower tooling costs compared to injection molding's expensive molds. Its resistance to yellowing and scratching ensures long-lasting, high-quality acrylic products suitable for display cases, lenses, and custom designs.

Benefits of Acrylic Injection Molding

Acrylic injection molding offers superior production efficiency and cost-effectiveness for large volume manufacturing compared to acrylic casting. This process provides enhanced precision and consistency, resulting in higher quality, more complex, and detailed parts with minimal post-processing. The automation capabilities reduce labor costs and improve scalability, making injection molding ideal for mass production of acrylic components.

Applications: When to Use Each Process

Acrylic casting is ideal for producing large, custom, and complex shapes with excellent optical clarity, making it suitable for high-end displays, aquariums, and architectural applications. Acrylic injection molding excels in high-volume production of smaller, precision parts like lenses, light covers, and medical devices due to its rapid cycle times and cost efficiency. Selecting between casting and injection molding depends on the required part size, complexity, clarity, and production volume for optimal application results.

Cost Comparison: Casting vs Injection Molding

Acrylic casting typically incurs higher labor and material costs due to its manual pouring and curing processes, making it more expensive for large production runs compared to injection molding. Injection molding offers lower per-unit costs and faster production cycles by using automated equipment and mold injection, which amortizes the initial mold expenses over high volumes. For small batch projects, casting remains cost-effective despite higher unit costs, while injection molding is economically advantageous for mass production due to its scalability and consistent quality.

Choosing the Right Process for Your Acrylic Product

Acrylic casting offers superior optical clarity and is ideal for custom, low-volume products requiring intricate details and thick sections. Acrylic injection molding excels in high-volume production with faster cycle times and consistent dimensional accuracy for thin-walled parts. Selecting the right process depends on factors like production volume, design complexity, and visual requirements to balance cost-efficiency and quality.

Acrylic Casting vs Acrylic Injection Molding Infographic

materialdif.com

materialdif.com