Acrylic welding creates stronger, more durable bonds by melting and fusing the plastic surfaces together, ideal for load-bearing or transparent projects where clarity is crucial. Acrylic gluing uses solvents or adhesives, offering a quicker and easier solution but often results in weaker joints that may yellow or crack over time. Choosing between welding and gluing acrylic depends on the desired strength, appearance, and long-term durability of the final product.

Table of Comparison

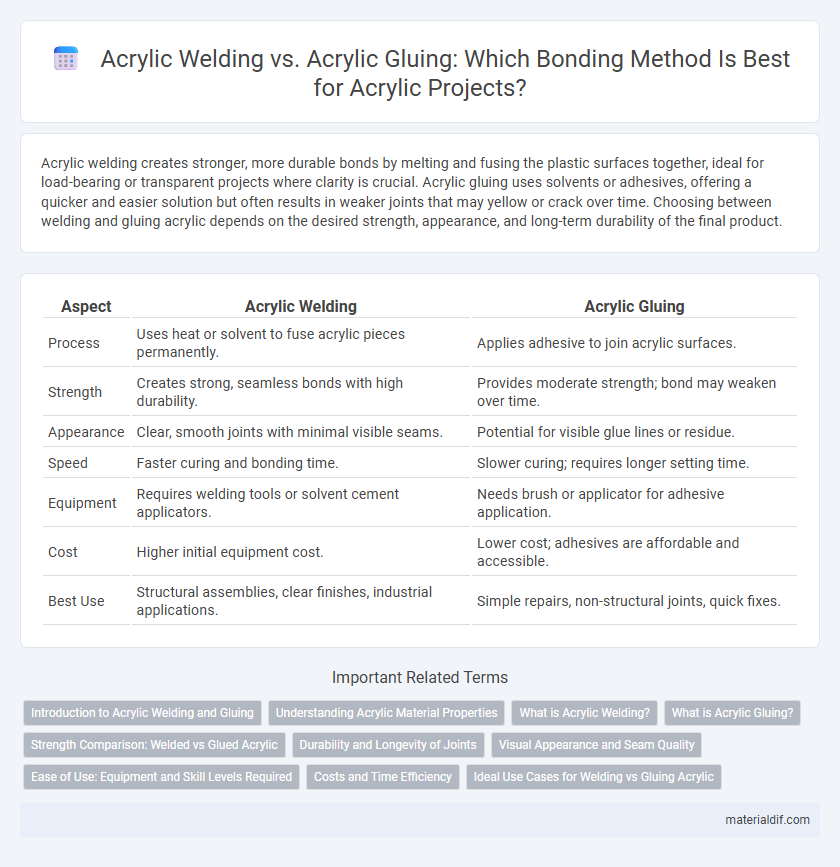

| Aspect | Acrylic Welding | Acrylic Gluing |

|---|---|---|

| Process | Uses heat or solvent to fuse acrylic pieces permanently. | Applies adhesive to join acrylic surfaces. |

| Strength | Creates strong, seamless bonds with high durability. | Provides moderate strength; bond may weaken over time. |

| Appearance | Clear, smooth joints with minimal visible seams. | Potential for visible glue lines or residue. |

| Speed | Faster curing and bonding time. | Slower curing; requires longer setting time. |

| Equipment | Requires welding tools or solvent cement applicators. | Needs brush or applicator for adhesive application. |

| Cost | Higher initial equipment cost. | Lower cost; adhesives are affordable and accessible. |

| Best Use | Structural assemblies, clear finishes, industrial applications. | Simple repairs, non-structural joints, quick fixes. |

Introduction to Acrylic Welding and Gluing

Acrylic welding involves the use of heat to fuse acrylic sheets, creating strong, seamless joints ideal for structural applications, while acrylic gluing utilizes specialized adhesives to bond surfaces chemically without heat. Welding provides greater durability and clarity in the joint compared to gluing, which offers ease of application and faster curing times. Both techniques are essential in acrylic fabrication, with the choice depending on project requirements such as strength, appearance, and speed.

Understanding Acrylic Material Properties

Acrylic welding creates a chemically fused bond by melting the acrylic surfaces, resulting in strong, clear joints ideal for load-bearing applications. Acrylic gluing relies on solvent-based adhesives that soften the acrylic to bond, offering ease and speed but typically less strength and clarity than welding. Understanding acrylic's thermoplastic properties, such as its sensitivity to heat and solvents, is essential to choosing the appropriate bonding method for durability and quality.

What is Acrylic Welding?

Acrylic welding is a technique that uses heat to fuse acrylic sheets, creating a strong, seamless bond ideal for structural applications. This method involves applying controlled heat, often with a hot air welder or solvent-assisted process, to soften the edges before joining. Compared to acrylic gluing, welding results in higher strength and clarity without the risk of adhesive residue or weakening the material.

What is Acrylic Gluing?

Acrylic gluing involves joining acrylic sheets using specialized adhesives that chemically bond the materials for a clear, durable finish. This method provides precision and smooth seams ideal for display cases, aquariums, and signage where aesthetic quality is crucial. Unlike acrylic welding, which uses heat to melt and fuse pieces, gluing avoids distortion and is better suited for delicate or complex shapes.

Strength Comparison: Welded vs Glued Acrylic

Welded acrylic joints demonstrate superior strength compared to glued acrylic, providing a seamless bond that closely matches the material's original integrity. Acrylic welding typically involves solvent or thermal fusion methods that create a homogeneous joint, whereas glued acrylic relies on adhesives that may introduce weak points and reduce load-bearing capacity. The mechanical strength of welded acrylic often surpasses glued counterparts by up to 30%, making welding the preferred choice for structural applications.

Durability and Longevity of Joints

Acrylic welding creates a strong, seamless bond by melting the material at the joint, resulting in superior durability and longevity compared to gluing methods. While acrylic gluing relies on adhesives that may degrade over time or under environmental stress, welded joints maintain structural integrity even under heavy use and exposure. For applications requiring long-lasting, robust connections, acrylic welding provides a more resilient and enduring solution than acrylic gluing.

Visual Appearance and Seam Quality

Acrylic welding produces a seamless, crystal-clear joint that closely matches the material's original appearance, enhancing both strength and aesthetic appeal. In contrast, acrylic gluing often results in visible seams and potential cloudiness due to adhesive residue or imperfect bonding. Welding offers superior durability and a polished finish, making it ideal for applications requiring high visual quality and structural integrity.

Ease of Use: Equipment and Skill Levels Required

Acrylic welding requires specialized equipment such as plastic welding guns or ultrasonic welders and demands a higher skill level to ensure strong, precise joints. Acrylic gluing involves simpler tools like applicator syringes and solvent-based adhesives, making it more accessible to beginners with minimal experience. Choosing between welding and gluing acrylic depends significantly on the user's technical proficiency and access to specialized tools.

Costs and Time Efficiency

Acrylic welding typically involves higher upfront equipment costs but offers faster joint curing times, making it more time-efficient for large-scale or structural applications. Acrylic gluing, while requiring lower initial investment in tools, often incurs longer drying periods and may demand repeated applications to ensure durability. Choosing between welding and gluing acrylic hinges on balancing budget constraints with project timelines and intended use.

Ideal Use Cases for Welding vs Gluing Acrylic

Acrylic welding is ideal for applications requiring strong, seamless bonds, such as structural components, aquariums, and display cases, where durability and clarity are critical. Acrylic gluing is best suited for small repairs, decorative items, or projects needing quick assembly without heavy mechanical stress. Welding provides superior strength and optical clarity, while gluing offers convenience and flexibility for less demanding uses.

Acrylic Welding vs Acrylic Gluing Infographic

materialdif.com

materialdif.com