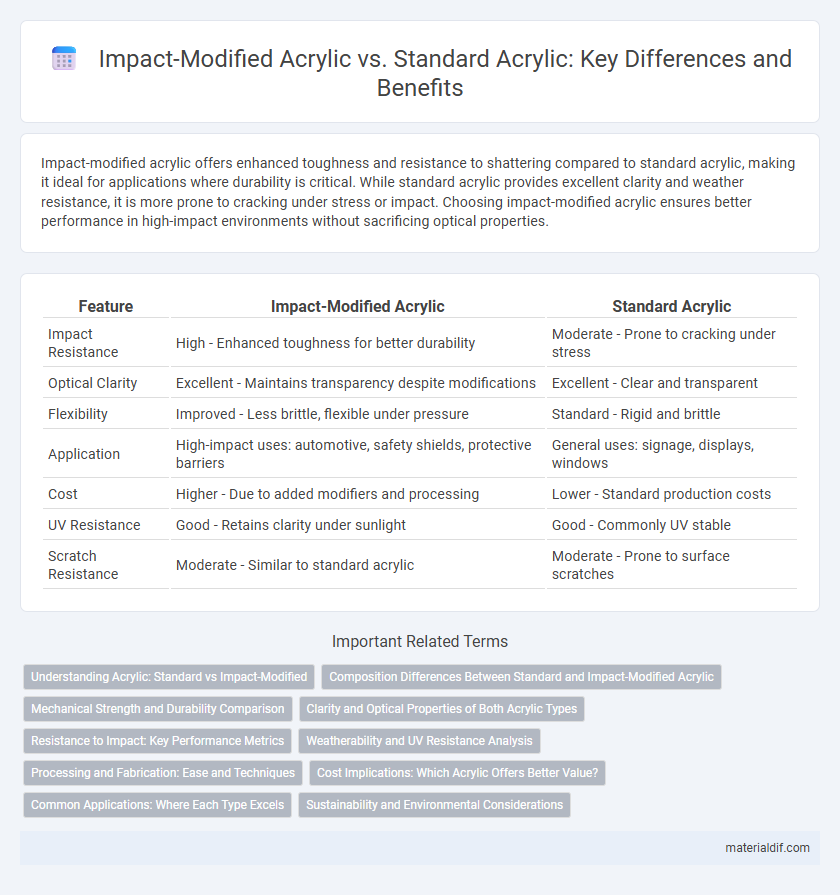

Impact-modified acrylic offers enhanced toughness and resistance to shattering compared to standard acrylic, making it ideal for applications where durability is critical. While standard acrylic provides excellent clarity and weather resistance, it is more prone to cracking under stress or impact. Choosing impact-modified acrylic ensures better performance in high-impact environments without sacrificing optical properties.

Table of Comparison

| Feature | Impact-Modified Acrylic | Standard Acrylic |

|---|---|---|

| Impact Resistance | High - Enhanced toughness for better durability | Moderate - Prone to cracking under stress |

| Optical Clarity | Excellent - Maintains transparency despite modifications | Excellent - Clear and transparent |

| Flexibility | Improved - Less brittle, flexible under pressure | Standard - Rigid and brittle |

| Application | High-impact uses: automotive, safety shields, protective barriers | General uses: signage, displays, windows |

| Cost | Higher - Due to added modifiers and processing | Lower - Standard production costs |

| UV Resistance | Good - Retains clarity under sunlight | Good - Commonly UV stable |

| Scratch Resistance | Moderate - Similar to standard acrylic | Moderate - Prone to surface scratches |

Understanding Acrylic: Standard vs Impact-Modified

Impact-modified acrylic contains rubber or other toughening agents blended into the polymer matrix to enhance its resistance to cracking and shattering, making it ideal for safety applications or environments prone to impact. Standard acrylic, often used for its excellent optical clarity and weather resistance, exhibits higher brittleness, which limits its use where mechanical strength is critical. The choice between standard and impact-modified acrylic depends on factors like required durability, application environment, and cost considerations.

Composition Differences Between Standard and Impact-Modified Acrylic

Impact-modified acrylic incorporates rubber or elastomeric polymers within its composition, enhancing its toughness and resistance to shattering compared to standard acrylic, which is a homopolymer primarily composed of polymethyl methacrylate (PMMA). This modification alters the polymer microstructure, increasing flexibility and impact strength while maintaining clarity and UV resistance typical of standard acrylic. The presence of these rubber modifiers in impact-modified acrylic helps absorb and dissipate energy upon impact, making it more suitable for safety applications than the more brittle standard acrylic.

Mechanical Strength and Durability Comparison

Impact-modified acrylic exhibits significantly enhanced mechanical strength and durability compared to standard acrylic, with improved resistance to cracking and shattering under stress. The molecular composition includes rubber toughening agents that absorb and dissipate impact energy, making it suitable for demanding applications such as automotive parts and protective barriers. Standard acrylic, while offering clarity and stiffness, lacks this impact resistance, making it more prone to brittle failure in high-stress environments.

Clarity and Optical Properties of Both Acrylic Types

Impact-modified acrylic maintains exceptional clarity with a light transmittance of approximately 92%, closely matching the brilliance of standard acrylic, which boasts about 93% light transmittance. The inclusion of impact modifiers slightly reduces the refractive index uniformity, leading to minor changes in optical properties while significantly enhancing toughness and resistance to shattering. Both types offer high optical clarity suitable for applications demanding transparency, but standard acrylic edges out in pure optical quality, making it preferable for precision optics.

Resistance to Impact: Key Performance Metrics

Impact-modified acrylic offers significantly enhanced resistance to impact compared to standard acrylic, with impact strength values often exceeding 15-20 kJ/m2 versus 4-6 kJ/m2 for standard grades. This improvement is achieved through the addition of impact modifiers such as rubber particles, which increase toughness and reduce brittleness without compromising optical clarity. Key performance metrics including Izod impact strength and tensile elongation at break are critical indicators, showing that impact-modified acrylic can absorb higher energy before fracturing, making it ideal for applications requiring durability and safety.

Weatherability and UV Resistance Analysis

Impact-modified acrylic exhibits enhanced weatherability and superior UV resistance compared to standard acrylic due to the incorporation of rubber particles that improve durability and prevent surface degradation. UV stabilizers in impact-modified acrylic reduce yellowing and cracking, extending the material's lifespan in outdoor environments. Standard acrylic, while clear and rigid, is more susceptible to UV-induced brittleness and color fading under prolonged sun exposure.

Processing and Fabrication: Ease and Techniques

Impact-modified acrylic offers enhanced toughness while maintaining similar processing and fabrication techniques as standard acrylic, such as extrusion, injection molding, and thermoforming. Both materials respond well to machining, laser cutting, and solvent bonding, although impact-modified acrylic may require slight adjustments in annealing times to prevent stress cracking. The improved impact resistance of modified acrylic reduces breakage during fabrication, making it preferable for complex or high-stress applications without significantly altering established processing workflows.

Cost Implications: Which Acrylic Offers Better Value?

Impact-modified acrylic typically costs 20-30% more than standard acrylic due to additives enhancing toughness and durability. While the initial expense is higher, impact-modified acrylic reduces long-term replacement and maintenance costs in high-stress environments. For applications demanding resilience and longevity, impact-modified acrylic offers better overall value despite its premium price.

Common Applications: Where Each Type Excels

Impact-modified acrylic is commonly used in safety glazing, automotive lenses, and protective barriers due to its enhanced shatter resistance and durability. Standard acrylic excels in applications such as signage, display cases, and lighting covers where clarity, UV resistance, and ease of fabrication are prioritized. Both types offer excellent optical clarity, but the choice depends on the balance between impact resistance and rigidity required for specific projects.

Sustainability and Environmental Considerations

Impact-modified acrylic enhances durability by incorporating rubber or other impact modifiers, reducing the need for frequent replacements and minimizing waste compared to standard acrylic. The extended lifespan of impact-modified acrylic lowers overall resource consumption and environmental impact through less manufacturing demand. Standard acrylic, often more brittle, may lead to higher disposal rates and increased plastic pollution, making impact-modified variants a more sustainable choice in applications requiring toughness.

Impact-Modified Acrylic vs Standard Acrylic Infographic

materialdif.com

materialdif.com