Acrylic demonstrates exceptional UV resistance, maintaining clarity and strength when exposed to sunlight over extended periods. Its sunlight durability prevents yellowing, cracking, and warping, making it ideal for outdoor applications. Compared to other plastics, acrylic offers superior protection against UV-related degradation, ensuring long-lasting performance in harsh environments.

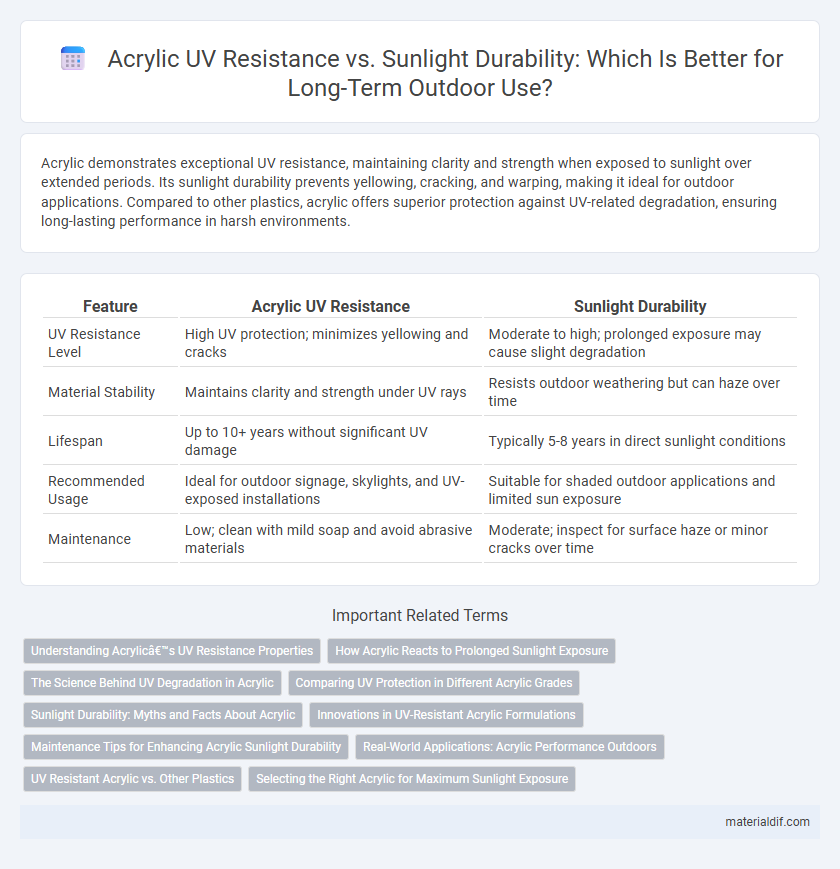

Table of Comparison

| Feature | Acrylic UV Resistance | Sunlight Durability |

|---|---|---|

| UV Resistance Level | High UV protection; minimizes yellowing and cracks | Moderate to high; prolonged exposure may cause slight degradation |

| Material Stability | Maintains clarity and strength under UV rays | Resists outdoor weathering but can haze over time |

| Lifespan | Up to 10+ years without significant UV damage | Typically 5-8 years in direct sunlight conditions |

| Recommended Usage | Ideal for outdoor signage, skylights, and UV-exposed installations | Suitable for shaded outdoor applications and limited sun exposure |

| Maintenance | Low; clean with mild soap and avoid abrasive materials | Moderate; inspect for surface haze or minor cracks over time |

Understanding Acrylic’s UV Resistance Properties

Acrylic exhibits excellent UV resistance, maintaining clarity and structural integrity even after prolonged exposure to sunlight, making it ideal for outdoor applications such as signage and glazing. Unlike other plastics, acrylic resists yellowing and surface deterioration caused by ultraviolet rays, thanks to its inherent polymer composition and UV stabilizers. This UV resistance directly enhances sunlight durability, ensuring that acrylic materials retain their aesthetic and mechanical properties over time without significant degradation.

How Acrylic Reacts to Prolonged Sunlight Exposure

Acrylic exhibits superior UV resistance compared to many plastics, maintaining clarity and structural integrity under prolonged sunlight exposure. Its molecular structure absorbs and disperses UV radiation, minimizing yellowing and brittleness over time. This durability makes acrylic an ideal material for outdoor applications requiring long-term sun exposure resilience.

The Science Behind UV Degradation in Acrylic

Acrylic's UV resistance stems from its chemical structure, which absorbs and dissipates ultraviolet radiation, reducing polymer chain breakdown. Prolonged exposure to sunlight causes photodegradation as UV photons generate free radicals, leading to surface cracking and yellowing. Manufacturers enhance sunlight durability by incorporating UV stabilizers and absorbers that inhibit molecular damage and prolong the lifespan of acrylic products.

Comparing UV Protection in Different Acrylic Grades

Acrylic exhibits varying UV protection levels depending on the grade, with UV-resistant acrylic providing superior blockage of harmful ultraviolet rays compared to standard grades. High-grade UV protection acrylic maintains clarity and structural integrity under prolonged sunlight, reducing yellowing and brittleness over time. Lower-grade acrylics, while transparent and durable initially, tend to degrade faster when exposed to intense sunlight due to insufficient UV stabilizers.

Sunlight Durability: Myths and Facts About Acrylic

Acrylic is often praised for its exceptional sunlight durability, but myths about its UV resistance can lead to misconceptions. While acrylic naturally blocks most UV rays, prolonged exposure without protective coatings may cause gradual yellowing and brittleness. Properly formulated acrylic sheets with UV inhibitors significantly extend lifespan, making them ideal for outdoor applications where long-term clarity and strength are essential.

Innovations in UV-Resistant Acrylic Formulations

Innovations in UV-resistant acrylic formulations have significantly enhanced sunlight durability by incorporating advanced UV stabilizers and inhibitors that prevent degradation and yellowing. These cutting-edge additives extend the lifespan of acrylic materials in outdoor applications, maintaining clarity and structural integrity even under prolonged solar exposure. Research in polymer chemistry continues to optimize these formulations, balancing UV protection with mechanical strength for improved performance.

Maintenance Tips for Enhancing Acrylic Sunlight Durability

Acrylic exhibits high UV resistance but prolonged Sunlight exposure can cause gradual yellowing and surface degradation. Regular cleaning with mild soap and water prevents dirt buildup that accelerates wear, while applying UV-resistant coatings enhances protective properties against Sunlight damage. Avoid abrasive materials to maintain surface clarity and extend the lifespan of acrylic products exposed to outdoor environments.

Real-World Applications: Acrylic Performance Outdoors

Acrylic offers excellent UV resistance, maintaining clarity and structural integrity when exposed to prolonged sunlight, making it ideal for outdoor signage, skylights, and protective barriers. Its weatherability ensures minimal yellowing and brittleness compared to other plastics, enhancing durability in real-world outdoor environments. This combination of UV resistance and sunlight durability enables acrylic to perform reliably in applications requiring long-lasting transparency and toughness.

UV Resistant Acrylic vs. Other Plastics

UV resistant acrylic offers superior protection against ultraviolet radiation, maintaining clarity and structural integrity far longer than most other plastics such as polycarbonate or PVC. Its molecular structure includes UV stabilizers that prevent yellowing and brittleness after prolonged sun exposure, resulting in sustained visual appeal and durability. Compared to other plastics, UV resistant acrylic is ideal for outdoor applications where sunlight durability is critical, reducing maintenance and replacement costs.

Selecting the Right Acrylic for Maximum Sunlight Exposure

Acrylic with enhanced UV resistance is essential for applications exposed to prolonged sunlight, as it prevents yellowing and brittleness over time. Opt for UV-stabilized or co-extruded acrylic sheets specifically designed to withstand harsh sun exposure, ensuring long-term clarity and structural integrity. Selecting the right grade based on UV resistance ratings and outdoor durability tests maximizes the lifespan and performance of acrylic in outdoor environments.

Acrylic UV Resistance vs Sunlight Durability Infographic

materialdif.com

materialdif.com