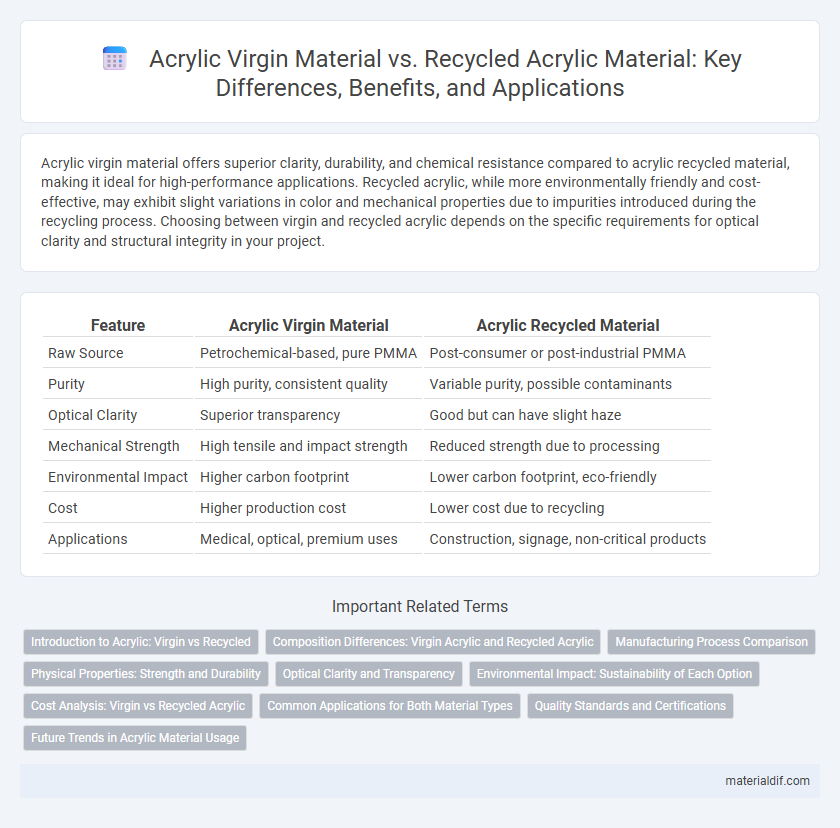

Acrylic virgin material offers superior clarity, durability, and chemical resistance compared to acrylic recycled material, making it ideal for high-performance applications. Recycled acrylic, while more environmentally friendly and cost-effective, may exhibit slight variations in color and mechanical properties due to impurities introduced during the recycling process. Choosing between virgin and recycled acrylic depends on the specific requirements for optical clarity and structural integrity in your project.

Table of Comparison

| Feature | Acrylic Virgin Material | Acrylic Recycled Material |

|---|---|---|

| Raw Source | Petrochemical-based, pure PMMA | Post-consumer or post-industrial PMMA |

| Purity | High purity, consistent quality | Variable purity, possible contaminants |

| Optical Clarity | Superior transparency | Good but can have slight haze |

| Mechanical Strength | High tensile and impact strength | Reduced strength due to processing |

| Environmental Impact | Higher carbon footprint | Lower carbon footprint, eco-friendly |

| Cost | Higher production cost | Lower cost due to recycling |

| Applications | Medical, optical, premium uses | Construction, signage, non-critical products |

Introduction to Acrylic: Virgin vs Recycled

Acrylic virgin material is derived directly from raw petrochemical sources, offering superior clarity, strength, and consistency for high-quality applications. Recycled acrylic material, produced from post-consumer or industrial acrylic waste, reduces environmental impact while maintaining reasonable optical and mechanical properties. Understanding the differences in origin, performance, and sustainability helps optimize material selection for manufacturing and design purposes.

Composition Differences: Virgin Acrylic and Recycled Acrylic

Virgin acrylic is composed of pure polymethyl methacrylate (PMMA) synthesized through controlled polymerization processes, ensuring consistent molecular weight and optical clarity. Recycled acrylic is derived from post-consumer or post-industrial acrylic waste, containing a mixture of PMMA with potential impurities, additives, or degraded polymer chains from previous use. The composition differences impact mechanical properties, color uniformity, and chemical resistance, with virgin acrylic typically offering superior performance and clarity compared to recycled acrylic blends.

Manufacturing Process Comparison

Acrylic virgin material is produced through polymerization of methyl methacrylate monomers, resulting in high-purity PMMA with consistent optical clarity and mechanical strength, ideal for precision applications. In contrast, recycled acrylic materials are derived from post-consumer or industrial PMMA waste, which undergoes cleaning, grinding, and re-polymerization processes that may introduce impurities and slightly alter material properties. Manufacturing recycled acrylic reduces reliance on fossil resources and energy consumption but requires stringent quality control to maintain performance standards comparable to virgin acrylic.

Physical Properties: Strength and Durability

Virgin acrylic material exhibits superior strength and enhanced durability compared to recycled acrylic, maintaining higher tensile strength and resistance to impact. Recycled acrylic often shows slight degradation in mechanical properties due to potential contamination and repeated processing, leading to reduced structural integrity. Industrial-grade virgin acrylic ensures consistent performance in demanding applications where long-term durability is critical.

Optical Clarity and Transparency

Acrylic virgin material offers superior optical clarity and transparency due to its purity and consistent polymer structure, resulting in higher light transmission and minimal impurities. Recycled acrylic material can exhibit reduced optical performance because of potential contaminants and slight polymer degradation during reprocessing, leading to decreased transparency and increased haze. Manufacturers choose virgin acrylic for applications demanding pristine visual quality, while recycled acrylic is preferred for cost-effective or eco-friendly products with less stringent optical requirements.

Environmental Impact: Sustainability of Each Option

Acrylic virgin material is derived from petrochemical sources, resulting in higher carbon emissions and resource depletion during production, which negatively impacts environmental sustainability. Recycled acrylic material significantly reduces landfill waste and lowers energy consumption by reusing existing polymers, contributing to a smaller ecological footprint. Choosing recycled acrylic supports circular economy principles, minimizing environmental impact while maintaining material performance.

Cost Analysis: Virgin vs Recycled Acrylic

Virgin acrylic material typically incurs higher production costs due to raw monomer purification and polymerization processes, resulting in premium pricing that reflects superior optical clarity and consistent quality. Recycled acrylic offers cost advantages by reusing post-consumer or post-industrial waste, reducing raw material expenses but may involve additional processing to remove impurities and maintain performance standards. Cost analysis reveals recycled acrylic can lower capital expenditure and environmental impact, making it economically attractive for applications where slight variations in transparency or mechanical properties are acceptable.

Common Applications for Both Material Types

Acrylic virgin material is widely used in high-clarity optical lenses, automotive parts, and medical devices due to its superior purity and strength. Recycled acrylic material finds common applications in construction panels, signage, and decorative items where sustainability and cost-effectiveness are prioritized. Both material types serve the manufacturing of display cases, lighting fixtures, and protective barriers, balancing performance with environmental impact.

Quality Standards and Certifications

Acrylic virgin material is produced from high-quality monomers ensuring superior clarity, durability, and consistent performance, meeting rigorous industry standards such as ASTM D3935 and ISO 15490. In contrast, acrylic recycled material undergoes processes that may impact optical clarity and mechanical strength but often complies with environmental certifications like GREENGUARD and Global Recycled Standard (GRS). Both materials adhere to specific quality certifications, with virgin acrylic excelling in purity and recycled acrylic emphasizing sustainability and compliance with eco-friendly manufacturing protocols.

Future Trends in Acrylic Material Usage

Acrylic virgin material maintains superior optical clarity and durability, driving demand in high-performance applications such as automotive and electronics. Recycled acrylic material gains traction due to sustainability goals and cost-effectiveness, leading to increased adoption in packaging and construction industries. Future trends indicate a balanced integration of both materials, leveraging virgin acrylic's quality and recycled acrylic's environmental benefits to meet evolving regulatory standards and consumer preferences.

Acrylic Virgin Material vs Acrylic Recycled Material Infographic

materialdif.com

materialdif.com