Acrylic pet exhibits a balance between brittleness and flexibility, making it suitable for various applications requiring transparency and durability. While acrylic tends to be more brittle compared to other plastics, its rigid structure provides excellent clarity and scratch resistance, but it can crack under high impact or stress. Flexibility in acrylic can be enhanced with additives or by using modified blends, which improve impact resistance without significantly compromising its optical properties.

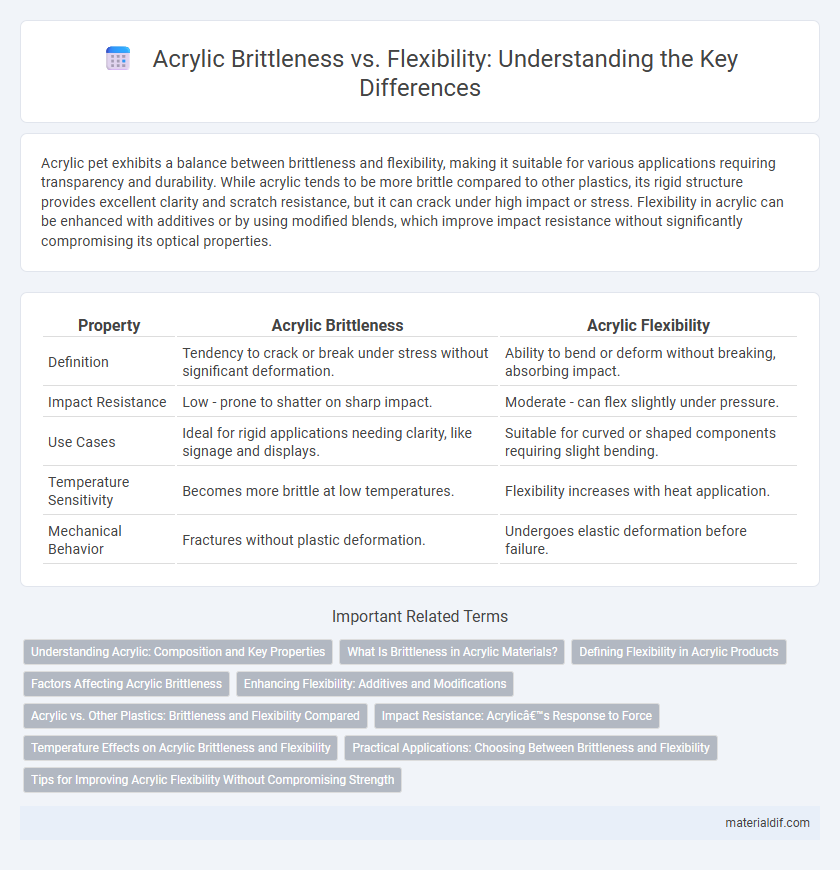

Table of Comparison

| Property | Acrylic Brittleness | Acrylic Flexibility |

|---|---|---|

| Definition | Tendency to crack or break under stress without significant deformation. | Ability to bend or deform without breaking, absorbing impact. |

| Impact Resistance | Low - prone to shatter on sharp impact. | Moderate - can flex slightly under pressure. |

| Use Cases | Ideal for rigid applications needing clarity, like signage and displays. | Suitable for curved or shaped components requiring slight bending. |

| Temperature Sensitivity | Becomes more brittle at low temperatures. | Flexibility increases with heat application. |

| Mechanical Behavior | Fractures without plastic deformation. | Undergoes elastic deformation before failure. |

Understanding Acrylic: Composition and Key Properties

Acrylic, also known as polymethyl methacrylate (PMMA), is a thermoplastic composed of polymerized methyl methacrylate monomers, which imparts both durability and clarity. Its molecular structure provides inherent brittleness due to rigid chains but can be tailored for flexibility through additives and copolymers, enhancing impact resistance without compromising transparency. Key properties such as tensile strength, elongation at break, and Young's modulus determine the balance between acrylic's brittleness and flexibility, making it suitable for diverse applications ranging from optical lenses to flexible display screens.

What Is Brittleness in Acrylic Materials?

Brittleness in acrylic materials refers to the tendency of the polymer to crack or break under stress without significant deformation. This characteristic is caused by the rigid molecular structure of polymethyl methacrylate (PMMA), which limits its ability to absorb impact energy. Understanding brittleness is crucial for applications requiring durability and resistance to sudden forces in acrylic products.

Defining Flexibility in Acrylic Products

Flexibility in acrylic products refers to the material's ability to bend or deform under stress without cracking or breaking, a key characteristic distinct from brittleness. Acrylic achieves flexibility through molecular structure modifications and additives that enhance its impact resistance and elongation at break. This balance allows acrylic sheets and components to withstand dynamic loads while maintaining optical clarity and durability in various applications.

Factors Affecting Acrylic Brittleness

Acrylic brittleness is influenced by factors such as temperature, UV exposure, and the presence of internal stresses. Low temperatures increase brittleness by reducing polymer chain mobility, while prolonged UV exposure degrades the molecular structure, causing cracks and weakening. Manufacturing processes and the addition of plasticizers can enhance flexibility, reducing the likelihood of fracture under stress.

Enhancing Flexibility: Additives and Modifications

Enhancing flexibility in acrylic involves incorporating specific plasticizers such as phthalates or sebacates, which reduce brittleness by increasing polymer chain mobility. Copolymerization with flexible monomers like butyl acrylate or incorporating impact modifiers further improves elasticity and resistance to cracking under stress. These additives and chemical modifications optimize acrylic's mechanical performance for applications requiring both durability and flexibility.

Acrylic vs. Other Plastics: Brittleness and Flexibility Compared

Acrylic exhibits a balance between brittleness and flexibility, offering greater impact resistance and flexibility than glass but is generally more brittle compared to plastics like polycarbonate or polyethylene. Unlike polycarbonate, which provides exceptional toughness and high flexibility, acrylic tends to crack under high stress but maintains superior clarity and UV resistance. Compared to polyethylene, acrylic's rigidity leads to less flexibility, making it more prone to brittle failure in low temperatures or sharp impacts.

Impact Resistance: Acrylic’s Response to Force

Acrylic exhibits moderate brittleness compared to other plastics, which affects its impact resistance under force. While it offers good rigidity, acrylic can fracture or crack when subjected to sudden, high-impact blows due to its limited flexibility. Manufacturers often modify acrylic with additives or blend it with other materials to enhance its toughness and improve durability against impact.

Temperature Effects on Acrylic Brittleness and Flexibility

Acrylic's brittleness and flexibility are significantly influenced by temperature, with higher temperatures increasing its flexibility by allowing polymer chains to move more freely, while lower temperatures cause the material to become more brittle and prone to cracking. The glass transition temperature (Tg) of acrylic, typically around 105degC, marks the point where acrylic transitions from a rigid, glassy state to a more flexible, rubbery state. Maintaining acrylic use within its optimal temperature range is crucial for balancing durability and flexibility in applications such as lenses, displays, and signage.

Practical Applications: Choosing Between Brittleness and Flexibility

Acrylic's brittleness offers high clarity and rigidity essential for structural applications like display cases and protective barriers, where impact resistance is less critical. Flexible acrylic variants suit uses requiring slight bending and durability, such as curved panels and light diffusers, optimizing resilience against stress. Selecting between brittle and flexible acrylic depends on specific project demands for strength, transparency, and shape adaptability.

Tips for Improving Acrylic Flexibility Without Compromising Strength

Improving acrylic flexibility without compromising strength involves incorporating plasticizers like methyl methacrylate to enhance ductility while maintaining structural integrity. Controlled annealing processes reduce internal stresses, minimizing brittleness and preventing cracking under load. Selecting acrylic copolymers or blending with impact modifiers further optimizes the balance between toughness and flexibility for diverse applications.

Acrylic Brittleness vs Flexibility Infographic

materialdif.com

materialdif.com