Acrylic and Plexiglas are often used interchangeably, but Plexiglas is actually a brand name for high-quality acrylic sheets known for superior clarity and impact resistance. Acrylic offers excellent transparency, weather resistance, and versatility, making it ideal for various applications such as displays, windows, and protective barriers. Choosing between acrylic and Plexiglas depends on budget and specific performance requirements, with Plexiglas typically providing enhanced durability and optical properties.

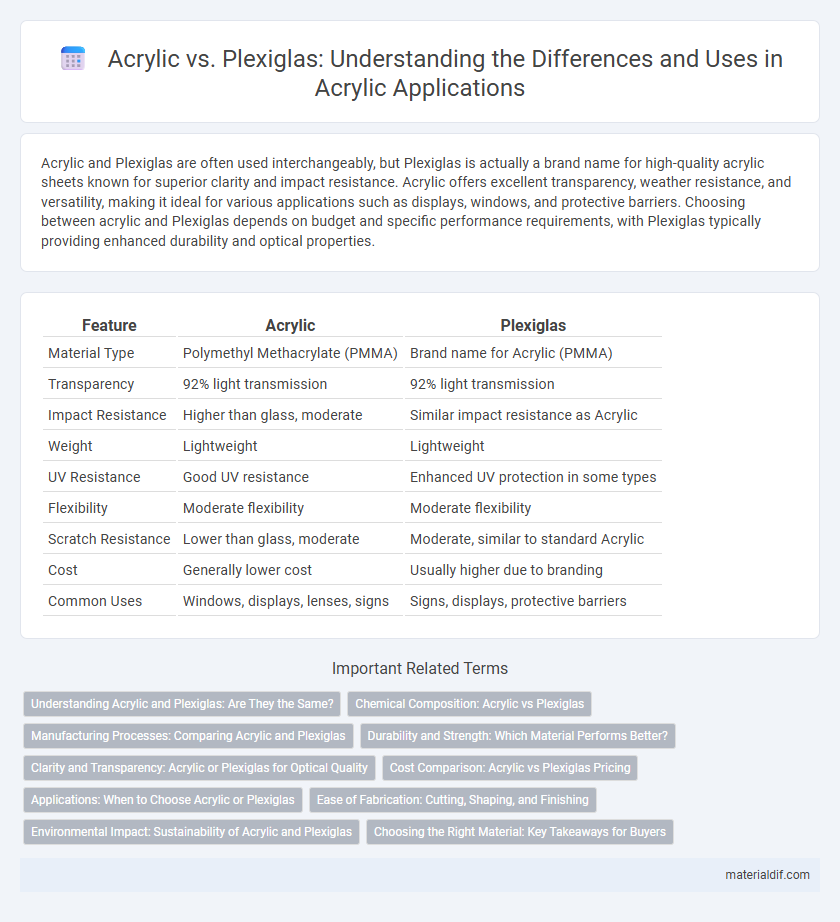

Table of Comparison

| Feature | Acrylic | Plexiglas |

|---|---|---|

| Material Type | Polymethyl Methacrylate (PMMA) | Brand name for Acrylic (PMMA) |

| Transparency | 92% light transmission | 92% light transmission |

| Impact Resistance | Higher than glass, moderate | Similar impact resistance as Acrylic |

| Weight | Lightweight | Lightweight |

| UV Resistance | Good UV resistance | Enhanced UV protection in some types |

| Flexibility | Moderate flexibility | Moderate flexibility |

| Scratch Resistance | Lower than glass, moderate | Moderate, similar to standard Acrylic |

| Cost | Generally lower cost | Usually higher due to branding |

| Common Uses | Windows, displays, lenses, signs | Signs, displays, protective barriers |

Understanding Acrylic and Plexiglas: Are They the Same?

Acrylic and Plexiglas are often used interchangeably, but Plexiglas is actually a brand name for a type of acrylic sheet made from polymethyl methacrylate (PMMA). Both materials share similar properties such as clarity, lightweight, and impact resistance, making them ideal substitutes for glass in various applications. Understanding that Plexiglas is a trademarked version of acrylic helps clarify their relationship without confusion in industrial or commercial use.

Chemical Composition: Acrylic vs Plexiglas

Acrylic and Plexiglas share the same primary chemical composition, polymethyl methacrylate (PMMA), which provides exceptional clarity and weather resistance. Plexiglas, a branded form of acrylic, often includes proprietary additives that enhance impact strength and UV stability compared to standard acrylic sheets. Both materials are widely used in applications requiring lightweight, shatter-resistant alternatives to glass, with slight variations in chemical formulation influencing durability and performance.

Manufacturing Processes: Comparing Acrylic and Plexiglas

Acrylic and Plexiglas share identical chemical compositions, both derived from polymethyl methacrylate (PMMA), but the manufacturing processes differ. Acrylic sheets are typically produced through bulk polymerization or polymer casting, resulting in high optical clarity and customizable thicknesses, while Plexiglas is a brand-name variant often made using continuous casting methods that ensure uniformity and scratch resistance. Understanding these production techniques highlights differences in cost, durability, and performance for applications requiring lightweight, shatter-resistant materials.

Durability and Strength: Which Material Performs Better?

Acrylic and Plexiglas both offer excellent durability and strength, but Plexiglas, a brand-name variant of acrylic, is engineered to provide superior impact resistance and greater tensile strength. Acrylic generally withstands heavy use and weathering, making it ideal for outdoor applications, while Plexiglas's enhanced molecular structure delivers improved shatter resistance and longevity under stress. For projects requiring maximum durability and strength, Plexiglas outperforms standard acrylic in maintaining clarity and structural integrity over time.

Clarity and Transparency: Acrylic or Plexiglas for Optical Quality

Acrylic and Plexiglas both offer exceptional clarity and transparency, with light transmittance rates reaching up to 92%, making them ideal for optical-quality applications. Plexiglas, a well-known brand of acrylic, is specially formulated to enhance optical clarity, reducing distortions and providing superior color stability over time. Acrylic sheets are widely preferred in industries requiring high transparency and minimal light diffusion, such as lenses, display cases, and aquariums.

Cost Comparison: Acrylic vs Plexiglas Pricing

Acrylic and Plexiglas pricing differ mainly due to brand reputation and manufacturing processes, with Plexiglas often costing 20-30% more than generic acrylic sheets. While both materials offer similar durability and clarity, the premium price of Plexiglas reflects its consistent quality control and longer warranty periods. Comparing prices per square foot, acrylic typically ranges from $7 to $15, whereas Plexiglas prices start around $10 and can exceed $18 depending on thickness and custom finishes.

Applications: When to Choose Acrylic or Plexiglas

Acrylic and Plexiglas are both versatile materials widely used in signage, displays, and protective barriers due to their clarity and durability. Choose acrylic for applications requiring superior UV resistance and higher impact strength, such as outdoor signs and aquarium windows. Plexiglas offers excellent optical clarity and is ideal for framing, skylights, and retail displays where clean aesthetics and ease of fabrication are priorities.

Ease of Fabrication: Cutting, Shaping, and Finishing

Acrylic and Plexiglas both offer excellent ease of fabrication, with Acrylic being highly favored for its smooth cutting, precise shaping, and clean finishing. Plexiglas, a brand of acrylic sheets, provides consistent transparency and durability while allowing intricate cuts and polished edges without cracking or chipping. Fabricators often choose Acrylic for custom projects due to its versatility in molding and seamless surface finishing capabilities.

Environmental Impact: Sustainability of Acrylic and Plexiglas

Acrylic and Plexiglas, both types of polymethyl methacrylate (PMMA), offer varying environmental impacts based on their production and recyclability. Acrylic is often considered more sustainable due to advances in recycling technologies that allow for more efficient recovery and reuse, reducing landfill waste. Plexiglas, while durable and long-lasting, generally requires more energy-intensive manufacturing processes, which can result in a higher carbon footprint compared to newer, eco-friendly acrylic alternatives.

Choosing the Right Material: Key Takeaways for Buyers

Acrylic and Plexiglas are essentially the same material, both being brands of polymethyl methacrylate (PMMA), prized for their clarity, durability, and lightweight properties. Buyers should consider factors like UV resistance, impact strength, and cost, as Plexiglas often offers superior UV protection while generic acrylic sheets may be more affordable. Selecting the right material depends on the specific application requirements, including outdoor exposure, budget constraints, and desired optical clarity.

Acrylic vs Plexiglas Infographic

materialdif.com

materialdif.com