Acrylic tubes are typically clear, lightweight, and used for decorative or display purposes, offering excellent optical clarity and smooth edges. Acrylic pipes are usually designed for plumbing or industrial applications, featuring thicker walls and enhanced durability to withstand pressure and environmental factors. Choosing between acrylic tube and pipe depends on the specific requirements for strength, transparency, and application environment.

Table of Comparison

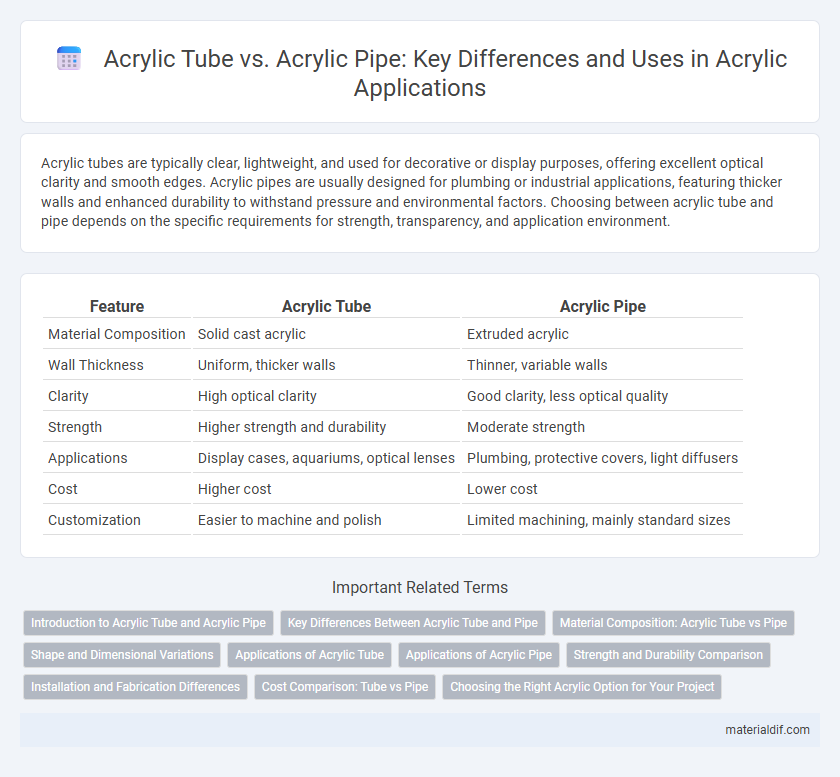

| Feature | Acrylic Tube | Acrylic Pipe |

|---|---|---|

| Material Composition | Solid cast acrylic | Extruded acrylic |

| Wall Thickness | Uniform, thicker walls | Thinner, variable walls |

| Clarity | High optical clarity | Good clarity, less optical quality |

| Strength | Higher strength and durability | Moderate strength |

| Applications | Display cases, aquariums, optical lenses | Plumbing, protective covers, light diffusers |

| Cost | Higher cost | Lower cost |

| Customization | Easier to machine and polish | Limited machining, mainly standard sizes |

Introduction to Acrylic Tube and Acrylic Pipe

Acrylic tubes and acrylic pipes are both cylindrical products made from polymethyl methacrylate (PMMA), valued for their clarity, strength, and weather resistance. Acrylic tubes feature a clear, seamless construction ideal for display cases, lighting fixtures, and aquarium applications, whereas acrylic pipes are typically designed for fluid transport and structural uses, often with thicker walls and standardized dimensions. Understanding the differences in wall thickness, diameter, and intended application helps in selecting the right acrylic product for specific engineering or decorative needs.

Key Differences Between Acrylic Tube and Pipe

Acrylic tube and acrylic pipe differ primarily in shape and wall thickness, with tubes typically featuring a circular profile and uniform thickness suited for decorative and precision applications, while pipes have thicker walls designed to withstand higher pressures in plumbing and industrial use. Acrylic tubes offer superior clarity and a smoother surface finish, making them ideal for display cases and lighting fixtures, whereas acrylic pipes prioritize structural strength and durability. Understanding these key differences helps in selecting the right material for projects requiring either aesthetic appeal or mechanical performance.

Material Composition: Acrylic Tube vs Pipe

Acrylic tubes and pipes are both fabricated from polymethyl methacrylate (PMMA), a transparent thermoplastic known for its clarity and strength. The primary difference lies in their manufacturing processes and wall thickness, with acrylic pipes typically designed for structural applications requiring higher pressure resistance and tubes favored for display and aesthetic uses. Material composition remains consistent, but pipe variants often undergo additional treatments to enhance durability and impact resistance.

Shape and Dimensional Variations

Acrylic tubes typically feature a seamless cylindrical shape with consistent wall thickness, making them ideal for applications requiring clear visibility and smooth surfaces. Acrylic pipes often have thicker walls and come in a broader range of diameters and lengths, designed for structural strength and fluid transport. Dimensional variations in acrylic tubes prioritize optical clarity and precision, whereas acrylic pipes emphasize durability and pressure resistance.

Applications of Acrylic Tube

Acrylic tubes are commonly used in applications requiring clarity, such as display cases, aquariums, and lighting fixtures, where transparency and aesthetic appeal are essential. Their smooth surface and ease of fabrication make them ideal for artistic installations, medical equipment, and signage that demand precision and visual clarity. Unlike acrylic pipes, which are typically designed for fluid transport, acrylic tubes focus on structural support and decorative purposes in architectural and retail environments.

Applications of Acrylic Pipe

Acrylic pipe is commonly used in applications requiring high transparency and durability, such as in aquariums, water fountains, and medical devices, where fluid flow visibility is crucial. Its superior impact resistance and chemical stability make it ideal for laboratory tubing and industrial fluid transport systems. Compared to acrylic tubes, acrylic pipes often feature thicker walls and standardized diameters, enhancing their strength and suitability for pressurized environments.

Strength and Durability Comparison

Acrylic tubes exhibit superior clarity and are often preferred in applications requiring high optical quality, but acrylic pipes generally offer enhanced strength due to thicker walls and reinforced construction. The durability of acrylic pipes surpasses that of acrylic tubes, making them more suitable for high-pressure and industrial environments. Choosing between the two depends on the balance needed between visual clarity and mechanical performance.

Installation and Fabrication Differences

Acrylic tubes are seamless and available in clear or colored forms, making them ideal for applications requiring smooth bends and detailed fabrication like bending or polishing. Acrylic pipes typically have thicker walls and standard dimensions suited for plumbing or structural uses, offering easier installation with compatible fittings and connectors. The fabrication of acrylic tubes demands precision cutting and heating techniques, whereas acrylic pipes focus more on joining methods such as solvent welding or mechanical assembly.

Cost Comparison: Tube vs Pipe

Acrylic tubes generally cost more than acrylic pipes due to their higher clarity and precise manufacturing, making them ideal for display and decorative uses. Acrylic pipes, designed primarily for fluid conveyance, tend to be more affordable because they are produced in bulk with less stringent clarity requirements. The cost difference is also influenced by wall thickness and diameter, with tubes often having thinner, more uniform walls compared to the thicker, more robust walls of pipes.

Choosing the Right Acrylic Option for Your Project

Acrylic tubes feature a hollow cylindrical shape with precise dimensions, ideal for projects requiring clear visibility and smooth finishes, while acrylic pipes are typically thicker and designed for structural or fluid transport applications. When choosing between acrylic tube and pipe, consider factors such as wall thickness, diameter, clarity, and load-bearing needs to ensure durability and performance. Selecting the right acrylic option enhances project outcomes by balancing aesthetic appeal with functional requirements.

Acrylic Tube vs Acrylic Pipe Infographic

materialdif.com

materialdif.com