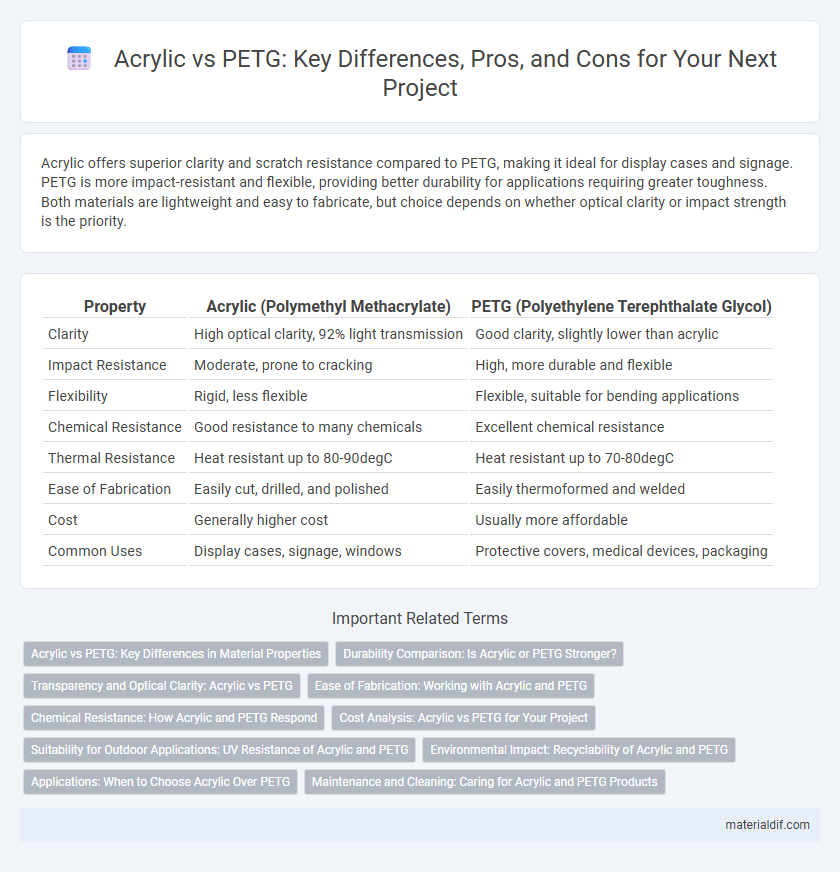

Acrylic offers superior clarity and scratch resistance compared to PETG, making it ideal for display cases and signage. PETG is more impact-resistant and flexible, providing better durability for applications requiring greater toughness. Both materials are lightweight and easy to fabricate, but choice depends on whether optical clarity or impact strength is the priority.

Table of Comparison

| Property | Acrylic (Polymethyl Methacrylate) | PETG (Polyethylene Terephthalate Glycol) |

|---|---|---|

| Clarity | High optical clarity, 92% light transmission | Good clarity, slightly lower than acrylic |

| Impact Resistance | Moderate, prone to cracking | High, more durable and flexible |

| Flexibility | Rigid, less flexible | Flexible, suitable for bending applications |

| Chemical Resistance | Good resistance to many chemicals | Excellent chemical resistance |

| Thermal Resistance | Heat resistant up to 80-90degC | Heat resistant up to 70-80degC |

| Ease of Fabrication | Easily cut, drilled, and polished | Easily thermoformed and welded |

| Cost | Generally higher cost | Usually more affordable |

| Common Uses | Display cases, signage, windows | Protective covers, medical devices, packaging |

Acrylic vs PETG: Key Differences in Material Properties

Acrylic exhibits higher scratch resistance and optical clarity compared to PETG, which offers superior impact resistance and flexibility. Acrylic maintains its rigidity and UV stability for outdoor applications, while PETG demonstrates better chemical resistance and easier thermoforming capabilities. These material properties make acrylic ideal for displays and signage, whereas PETG suits protective covers and packaging where durability and formability are critical.

Durability Comparison: Is Acrylic or PETG Stronger?

Acrylic offers high scratch resistance and excellent clarity, making it suitable for applications requiring optical precision, while PETG provides superior impact resistance and flexibility, reducing the risk of cracking under stress. PETG's enhanced durability under mechanical pressure makes it stronger in environments prone to bending or sudden impacts. Acrylic is more rigid but brittle, whereas PETG balances strength and durability with impact resilience.

Transparency and Optical Clarity: Acrylic vs PETG

Acrylic offers superior transparency and optical clarity, with light transmittance reaching up to 92%, making it ideal for applications requiring crystal-clear visibility. PETG, while also transparent, typically exhibits slightly lower optical clarity with light transmittance around 86-89%, and may show a slight haze under certain conditions. The higher refractive index and better surface finish of acrylic contribute to its enhanced clarity compared to PETG.

Ease of Fabrication: Working with Acrylic and PETG

Acrylic offers excellent ease of fabrication due to its rigidity and ability to be precisely cut, drilled, and polished, resulting in clean edges and a professional finish ideal for signage and displays. PETG, known for its superior impact resistance and flexibility, allows for easier thermoforming and bending without cracking, making it suitable for complex shapes and protective covers. Both materials can be laser cut, but PETG generally heats faster and softens at lower temperatures, reducing the risk of burning or brittleness during fabrication processes.

Chemical Resistance: How Acrylic and PETG Respond

Acrylic exhibits moderate chemical resistance, performing well against alkalis and mild acids but susceptible to damage from solvents like acetone and alcohols. PETG offers superior chemical resistance, maintaining integrity when exposed to many chemicals, including acids, alkalis, and alcohols, making it more durable in harsh environments. Both materials resist water and humidity, but PETG is preferred for applications requiring higher resistance to chemical exposure.

Cost Analysis: Acrylic vs PETG for Your Project

Acrylic typically costs less per sheet than PETG, making it a more budget-friendly option for projects with tight financial constraints. PETG offers greater durability and impact resistance, which can reduce long-term replacement and maintenance expenses despite its higher initial price. Evaluating both material costs and project requirements ensures an optimal balance between upfront investment and product longevity.

Suitability for Outdoor Applications: UV Resistance of Acrylic and PETG

Acrylic offers superior UV resistance, making it highly suitable for outdoor applications where prolonged sun exposure occurs, as it resists yellowing and maintains clarity over time. PETG, while more impact-resistant, is less UV stable and may degrade or discolor faster under continuous UV exposure. Choosing acrylic ensures long-lasting durability and aesthetic appeal in outdoor environments requiring UV protection.

Environmental Impact: Recyclability of Acrylic and PETG

Acrylic and PETG differ significantly in their environmental impact, particularly in recyclability. Acrylic (PMMA) is less commonly recycled due to limited facilities and is often downcycled or sent to landfill, whereas PETG is more easily recycled with established systems converting it back into usable material. Choosing PETG supports better circular economy practices due to its higher recyclability and reduced environmental footprint compared to acrylic.

Applications: When to Choose Acrylic Over PETG

Acrylic is ideal for applications requiring superior optical clarity, UV resistance, and rigidity, making it the preferred choice for high-quality displays, signage, and picture frames. Its ability to maintain transparency over time and resist scratches better than PETG suits environments exposed to sunlight and frequent handling. Acrylic also excels in decorative and indoor applications where stiffness and a glass-like finish are essential, whereas PETG is favored for impact resistance and flexible applications.

Maintenance and Cleaning: Caring for Acrylic and PETG Products

Acrylic surfaces require gentle cleaning with a soft cloth and mild soap to prevent scratches and maintain clarity, avoiding ammonia-based or abrasive cleaners that can damage the material. PETG offers greater chemical resistance and durability, allowing for more aggressive cleaning agents without compromising its surface integrity. Regular dusting and prompt removal of stains extend the lifespan and appearance of both acrylic and PETG products.

Acrylic vs PETG Infographic

materialdif.com

materialdif.com