Acrylic adhesive offers superior flexibility and UV resistance, making it ideal for bonding acrylic pet materials without causing cracking or yellowing over time. Cyanoacrylate adhesive provides rapid bonding strength but may lead to brittleness and fogging when used on acrylic pet surfaces. Choosing the right adhesive depends on the application requirements, with acrylic adhesives preferred for durability and cyanoacrylate for quick repairs.

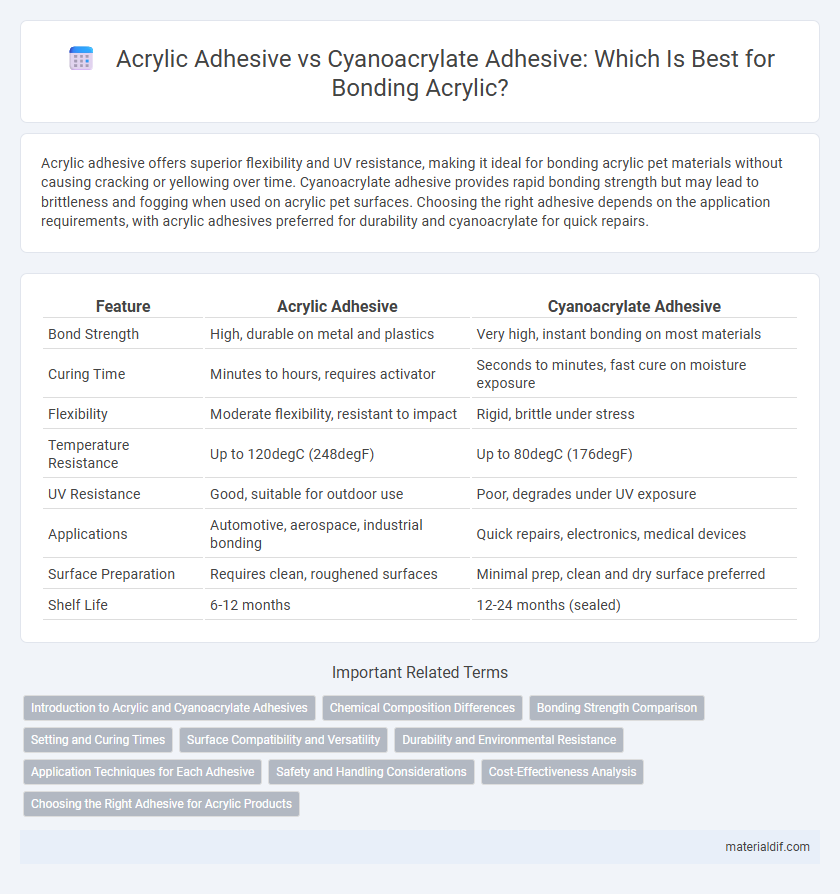

Table of Comparison

| Feature | Acrylic Adhesive | Cyanoacrylate Adhesive |

|---|---|---|

| Bond Strength | High, durable on metal and plastics | Very high, instant bonding on most materials |

| Curing Time | Minutes to hours, requires activator | Seconds to minutes, fast cure on moisture exposure |

| Flexibility | Moderate flexibility, resistant to impact | Rigid, brittle under stress |

| Temperature Resistance | Up to 120degC (248degF) | Up to 80degC (176degF) |

| UV Resistance | Good, suitable for outdoor use | Poor, degrades under UV exposure |

| Applications | Automotive, aerospace, industrial bonding | Quick repairs, electronics, medical devices |

| Surface Preparation | Requires clean, roughened surfaces | Minimal prep, clean and dry surface preferred |

| Shelf Life | 6-12 months | 12-24 months (sealed) |

Introduction to Acrylic and Cyanoacrylate Adhesives

Acrylic adhesives are known for their strong bonding capabilities, resistance to environmental factors, and versatility in bonding various substrates such as metals, plastics, and glass. Cyanoacrylate adhesives, commonly referred to as super glues, offer rapid curing times and exceptional strength for bonding non-porous materials like rubber, ceramics, and some plastics. Both adhesives serve critical roles in industrial and household applications, with acrylic adhesives excelling in durability and cyanoacrylates favored for quick repairs.

Chemical Composition Differences

Acrylic adhesives consist of polymerized acrylic acid esters, providing excellent flexibility, UV resistance, and durability, while cyanoacrylate adhesives are composed of cyanoacrylate monomers that rapidly polymerize in the presence of moisture to form strong, rigid bonds. The chemical structure of acrylic adhesives includes long polymer chains that enable resistance to environmental factors, whereas cyanoacrylate adhesives form a rigid, brittle polymer network optimized for quick bonding of non-porous surfaces. Differences in chemical composition directly influence their applications, with acrylic adhesives preferred for flexible, durable joints and cyanoacrylates favored for fast, high-strength bonding.

Bonding Strength Comparison

Acrylic adhesive offers superior bonding strength on a wide range of substrates, including metals, plastics, and glass, due to its excellent gap-filling properties and high shear and peel resistance. Cyanoacrylate adhesive provides rapid curing and strong bonds on non-porous surfaces but tends to be more brittle, making it less effective for applications requiring flexibility or impact resistance. Overall, acrylic adhesives outperform cyanoacrylates in long-term durability and bonding strength under stress or environmental exposure.

Setting and Curing Times

Acrylic adhesive typically offers longer setting and curing times, ranging from minutes to several hours, which allows for repositioning and ensures strong bonding on various substrates. Cyanoacrylate adhesive cures almost instantly within seconds to a minute upon contact with moisture, providing rapid bonding but with less flexibility during application. The extended curing time of acrylic adhesives supports high-performance, durable joints, while cyanoacrylate is ideal for quick repairs and bonding small surfaces.

Surface Compatibility and Versatility

Acrylic adhesives exhibit superior surface compatibility, effectively bonding to a wide range of materials including metals, plastics, and glass due to their chemical resistance and flexibility. Cyanoacrylate adhesives, known for their rapid curing times, bond well with non-porous surfaces like metals and ceramics but struggle with flexible or oily substrates. Versatility in acrylic adhesives stems from their tolerance to varying environmental conditions and ability to maintain strong bonds on dissimilar materials, unlike cyanoacrylates which are best suited for quick, rigid bonds on clean, smooth surfaces.

Durability and Environmental Resistance

Acrylic adhesives offer superior durability with excellent resistance to UV radiation, moisture, and temperature fluctuations, making them ideal for outdoor and industrial applications. Cyanoacrylate adhesives bond quickly but tend to be more brittle and susceptible to degradation under prolonged exposure to heat and humidity. The choice between acrylic and cyanoacrylate depends on the required longevity and environmental conditions of the bonded materials.

Application Techniques for Each Adhesive

Acrylic adhesives require precise surface preparation and usually involve applying a primer to enhance bonding strength, making them ideal for bonding metals, plastics, and composites in automotive and aerospace industries. Cyanoacrylate adhesives cure rapidly with moisture, enabling fast bonding of small parts and medical devices, often applied in thin layers to ensure strong, instant adhesion on substrates like rubber, metal, and ceramics. Both adhesives benefit from controlled application techniques tailored to substrate types and environmental conditions to optimize bond durability and performance.

Safety and Handling Considerations

Acrylic adhesives require careful ventilation due to the release of volatile organic compounds (VOCs) during curing, while cyanoacrylate adhesives pose risks of skin and eye irritation and rapid bonding upon contact, necessitating the use of gloves and eye protection. Proper storage for acrylic adhesives involves maintaining controlled temperatures to prevent premature polymerization, whereas cyanoacrylates must be kept in airtight containers to avoid moisture-induced curing. Both adhesives demand adherence to safety data sheet (SDS) guidelines to minimize health hazards and ensure safe handling in industrial and laboratory settings.

Cost-Effectiveness Analysis

Acrylic adhesive typically offers greater cost-effectiveness for large-scale industrial applications due to its balance of strong bonding and durability at a lower price point compared to cyanoacrylate adhesive. Cyanoacrylate adhesive, known for rapid curing and excellent adhesion to a variety of materials, tends to be more expensive per unit volume but is beneficial for small precision repairs, reducing material waste. When evaluating total project expenses, acrylic adhesives present a more economical choice for volume bonding, while cyanoacrylate remains cost-effective for fast-setting, low-quantity tasks.

Choosing the Right Adhesive for Acrylic Products

Acrylic adhesive offers superior UV resistance and flexibility, making it ideal for bonding acrylic products exposed to sunlight or thermal expansion. Cyanoacrylate adhesive provides rapid curing and strong initial tack but may cause stress cracking on acrylic surfaces due to its brittle nature. Selecting the right adhesive depends on the application's environmental conditions and mechanical demands to ensure durable, crack-free bonds.

Acrylic Adhesive vs Cyanoacrylate Adhesive Infographic

materialdif.com

materialdif.com