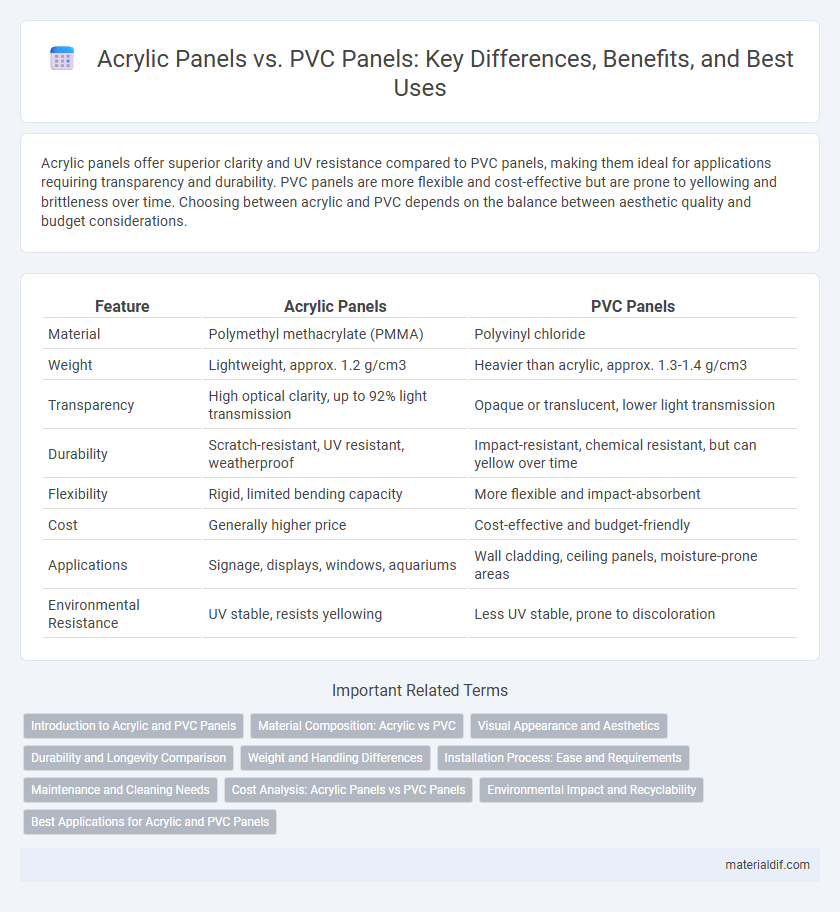

Acrylic panels offer superior clarity and UV resistance compared to PVC panels, making them ideal for applications requiring transparency and durability. PVC panels are more flexible and cost-effective but are prone to yellowing and brittleness over time. Choosing between acrylic and PVC depends on the balance between aesthetic quality and budget considerations.

Table of Comparison

| Feature | Acrylic Panels | PVC Panels |

|---|---|---|

| Material | Polymethyl methacrylate (PMMA) | Polyvinyl chloride |

| Weight | Lightweight, approx. 1.2 g/cm3 | Heavier than acrylic, approx. 1.3-1.4 g/cm3 |

| Transparency | High optical clarity, up to 92% light transmission | Opaque or translucent, lower light transmission |

| Durability | Scratch-resistant, UV resistant, weatherproof | Impact-resistant, chemical resistant, but can yellow over time |

| Flexibility | Rigid, limited bending capacity | More flexible and impact-absorbent |

| Cost | Generally higher price | Cost-effective and budget-friendly |

| Applications | Signage, displays, windows, aquariums | Wall cladding, ceiling panels, moisture-prone areas |

| Environmental Resistance | UV stable, resists yellowing | Less UV stable, prone to discoloration |

Introduction to Acrylic and PVC Panels

Acrylic panels are lightweight, impact-resistant sheets made from polymethyl methacrylate (PMMA), known for their clarity and UV resistance, making them ideal for optical and outdoor applications. PVC panels, derived from polyvinyl chloride, offer superior chemical resistance, flame retardancy, and cost-effectiveness, widely used in construction and industrial environments. Both materials provide distinct advantages: acrylic prioritizes aesthetic appeal and transparency, while PVC emphasizes durability and versatility.

Material Composition: Acrylic vs PVC

Acrylic panels are made from polymethyl methacrylate (PMMA), a transparent thermoplastic known for its clarity, rigidity, and resistance to UV light, making it ideal for outdoor and display applications. PVC panels consist of polyvinyl chloride, a synthetic plastic polymer characterized by durability, chemical resistance, and ease of fabrication, often used in construction and signage. Compared to PVC, acrylic offers superior optical clarity and scratch resistance, while PVC provides greater impact resistance and fire retardancy benefits.

Visual Appearance and Aesthetics

Acrylic panels offer superior clarity and gloss, providing a sleek, glass-like finish that enhances visual appeal compared to the matte or slightly dull surface of PVC panels. The high light transmission and vibrant color retention of acrylic panels make them ideal for displays and decorative applications where aesthetics are paramount. PVC panels often lack the depth and brilliance of acrylic, making them less suitable for projects requiring a premium, polished look.

Durability and Longevity Comparison

Acrylic panels exhibit superior durability and longevity compared to PVC panels due to their high resistance to UV radiation, weathering, and impact, making them ideal for outdoor applications. Acrylic's molecular structure offers enhanced scratch resistance and maintains clarity over time without yellowing, unlike PVC panels that tend to become brittle and discolor with prolonged exposure. Manufacturers often choose acrylic panels for their extended lifespan, which can exceed 10 years under harsh conditions, whereas PVC panels typically last around 5 to 7 years before significant degradation occurs.

Weight and Handling Differences

Acrylic panels are significantly lighter than PVC panels, offering easier handling and installation, especially in large-scale projects. The reduced weight of acrylic minimizes transportation costs and lowers the risk of damage during handling. In contrast, PVC panels are heavier and more rigid, which can complicate maneuverability and extend labor time in installation processes.

Installation Process: Ease and Requirements

Acrylic panels offer a lightweight design that simplifies handling and cutting during installation, requiring basic tools such as a saw and adhesive or screws. PVC panels are heavier but often come with tongue-and-groove edges, enabling quicker alignment and secure fitting, often minimizing the need for adhesives. Both materials require surface preparation, but acrylic panels demand more careful handling to avoid cracking, while PVC panels provide greater flexibility and durability in varied installation environments.

Maintenance and Cleaning Needs

Acrylic panels require minimal maintenance due to their non-porous surface, which resists stains and makes cleaning easy with mild soap and water. PVC panels, while also low-maintenance, can accumulate dirt in textured finishes and may need specialized cleaners to avoid surface damage. Both materials offer durability, but acrylic's smoother finish simplifies routine cleaning tasks and reduces long-term upkeep costs.

Cost Analysis: Acrylic Panels vs PVC Panels

Acrylic panels generally cost more than PVC panels due to higher raw material and manufacturing expenses. While acrylic offers superior clarity and durability, PVC panels provide a more budget-friendly option with acceptable performance for many applications. Cost analysis should consider long-term value, as acrylic's resistance to yellowing and scratches may reduce replacement and maintenance expenses over time.

Environmental Impact and Recyclability

Acrylic panels are made from polymethyl methacrylate (PMMA), a durable plastic that can be recycled, reducing environmental waste when properly processed. PVC panels contain polyvinyl chloride, which poses challenges for recycling due to toxic additives and potential release of harmful chemicals during disposal. The environmental impact of acrylic is generally lower than PVC, as acrylic panels offer better recyclability and minimal release of hazardous substances.

Best Applications for Acrylic and PVC Panels

Acrylic panels excel in applications requiring high clarity, UV resistance, and impact strength, making them ideal for signage, display cases, and aquariums where optical transparency is critical. PVC panels offer superior chemical resistance, durability, and moisture resistance, suitable for wall cladding, outdoor advertising, and industrial environments exposed to harsh conditions. Choosing between acrylic and PVC panels depends on specific needs for transparency, weather resistance, and mechanical strength in the intended application.

Acrylic Panels vs PVC Panels Infographic

materialdif.com

materialdif.com