Acrylic injection molding produces high-precision, complex shapes with superior surface finish and strength, ideal for detailed and durable components. Acrylic thermoforming offers cost-effective, large-volume manufacturing of simpler shapes by heating and shaping sheets, suitable for lightweight and flexible designs. Choosing between the two depends on project complexity, production volume, and mechanical property requirements.

Table of Comparison

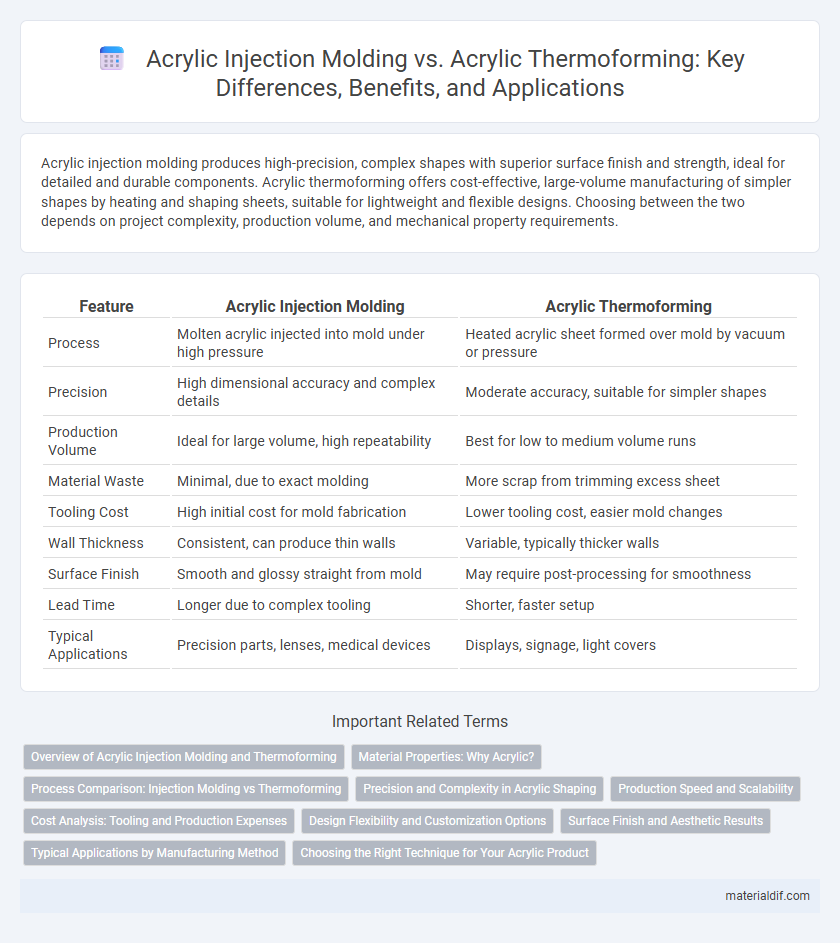

| Feature | Acrylic Injection Molding | Acrylic Thermoforming |

|---|---|---|

| Process | Molten acrylic injected into mold under high pressure | Heated acrylic sheet formed over mold by vacuum or pressure |

| Precision | High dimensional accuracy and complex details | Moderate accuracy, suitable for simpler shapes |

| Production Volume | Ideal for large volume, high repeatability | Best for low to medium volume runs |

| Material Waste | Minimal, due to exact molding | More scrap from trimming excess sheet |

| Tooling Cost | High initial cost for mold fabrication | Lower tooling cost, easier mold changes |

| Wall Thickness | Consistent, can produce thin walls | Variable, typically thicker walls |

| Surface Finish | Smooth and glossy straight from mold | May require post-processing for smoothness |

| Lead Time | Longer due to complex tooling | Shorter, faster setup |

| Typical Applications | Precision parts, lenses, medical devices | Displays, signage, light covers |

Overview of Acrylic Injection Molding and Thermoforming

Acrylic injection molding involves melting acrylic pellets and injecting the molten material into precise molds, producing complex, high-strength parts with excellent optical clarity and surface finish. Acrylic thermoforming heats acrylic sheets to a pliable temperature before forming them over molds, ideal for larger, less detailed components with consistent thickness and lower tooling costs. Both processes cater to different production needs, with injection molding excelling in detailed, high-volume parts and thermoforming offering flexibility in shape and size for moderate runs.

Material Properties: Why Acrylic?

Acrylic injection molding offers superior dimensional stability and intricate detail capabilities due to higher pressure and temperature resistance compared to acrylic thermoforming. Acrylic thermoforming provides excellent optical clarity and impact resistance, ideal for simpler, larger shapes with uniform thickness. Choosing acrylic leverages its outstanding weatherability, UV resistance, and hardness, ensuring durable, clear, and aesthetically pleasing products across both manufacturing methods.

Process Comparison: Injection Molding vs Thermoforming

Acrylic injection molding involves melting raw acrylic pellets and injecting them into a precision-engineered mold, producing highly detailed and complex parts with excellent dimensional accuracy. Thermoforming acrylic sheets requires heating the sheet until pliable, then shaping it over a mold through vacuum or pressure, making it suitable for larger, less intricate parts with faster production cycles. Injection molding offers superior surface finish and mechanical properties, while thermoforming provides cost-effective tooling and flexibility for moderate complexity designs.

Precision and Complexity in Acrylic Shaping

Acrylic injection molding offers superior precision and the ability to create intricate, complex shapes with tight tolerances, making it ideal for high-detail components. In contrast, acrylic thermoforming is better suited for simpler designs with moderate precision, as it involves heating and shaping sheets over molds, which limits fine detail and intricate geometries. Manufacturers select injection molding when exact dimensions and complex features are critical, while thermoforming is chosen for faster, cost-effective production of less detailed acrylic parts.

Production Speed and Scalability

Acrylic injection molding offers faster production speeds due to automated processes and rapid cycle times, making it ideal for large-volume manufacturing. Thermoforming acrylic, while suitable for medium-scale runs, involves slower heating and forming steps, limiting scalability. Injection molding ensures consistent high throughput and scalability for complex geometries, whereas thermoforming is better suited for simpler designs and lower production volumes.

Cost Analysis: Tooling and Production Expenses

Acrylic injection molding requires high initial tooling costs due to the precision and durability of steel molds, but offers lower per-unit production expenses ideal for large-scale manufacturing. Acrylic thermoforming involves significantly lower tooling costs with flexible, less durable molds, making it economically advantageous for small to medium production runs. Evaluating production volume and budget constraints is crucial for determining the most cost-effective acrylic fabrication method.

Design Flexibility and Customization Options

Acrylic injection molding offers superior design flexibility with intricate shapes, detailed features, and tight tolerances, enabling complex and highly customized parts. Acrylic thermoforming allows for larger, simpler shapes but is limited in detail and customization compared to injection molding. The choice depends on whether precision and complexity or larger, less detailed forms are prioritized in the acrylic manufacturing process.

Surface Finish and Aesthetic Results

Acrylic injection molding produces parts with high precision and smooth surface finishes, resulting in consistent, glossy aesthetics ideal for clear, detailed designs. In contrast, acrylic thermoforming offers a cost-effective approach but may yield parts with slightly less uniform surfaces and minor texture variations due to heating and forming processes. Both methods provide visually appealing results, but injection molding excels in achieving superior clarity and fine detail for high-quality optical applications.

Typical Applications by Manufacturing Method

Acrylic injection molding is commonly used for producing complex, high-precision components such as optical lenses, medical devices, and automotive parts, where durability and detailed replication are critical. Acrylic thermoforming is ideal for larger, less intricate items like signage, displays, and protective barriers that require cost-effective shaping and quick production cycles. Each manufacturing method aligns with specific application needs, balancing design complexity and volume efficiency.

Choosing the Right Technique for Your Acrylic Product

Acrylic injection molding offers precise, high-volume production with complex shapes and excellent surface finishes, making it ideal for intricate designs and durability. Acrylic thermoforming provides cost-effective solutions for larger, simpler parts, enabling faster turnaround times and flexible thickness options. Evaluating product complexity, production volume, and budget will guide the choice between injection molding and thermoforming for optimal acrylic product performance.

Acrylic Injection Molding vs Acrylic Thermoforming Infographic

materialdif.com

materialdif.com