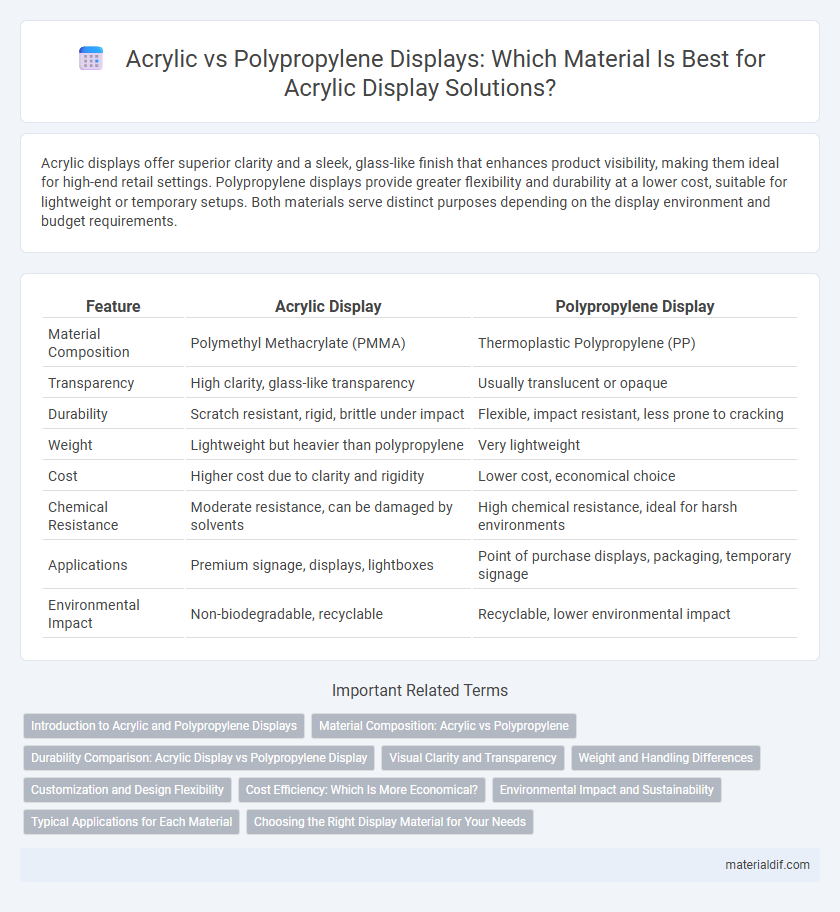

Acrylic displays offer superior clarity and a sleek, glass-like finish that enhances product visibility, making them ideal for high-end retail settings. Polypropylene displays provide greater flexibility and durability at a lower cost, suitable for lightweight or temporary setups. Both materials serve distinct purposes depending on the display environment and budget requirements.

Table of Comparison

| Feature | Acrylic Display | Polypropylene Display |

|---|---|---|

| Material Composition | Polymethyl Methacrylate (PMMA) | Thermoplastic Polypropylene (PP) |

| Transparency | High clarity, glass-like transparency | Usually translucent or opaque |

| Durability | Scratch resistant, rigid, brittle under impact | Flexible, impact resistant, less prone to cracking |

| Weight | Lightweight but heavier than polypropylene | Very lightweight |

| Cost | Higher cost due to clarity and rigidity | Lower cost, economical choice |

| Chemical Resistance | Moderate resistance, can be damaged by solvents | High chemical resistance, ideal for harsh environments |

| Applications | Premium signage, displays, lightboxes | Point of purchase displays, packaging, temporary signage |

| Environmental Impact | Non-biodegradable, recyclable | Recyclable, lower environmental impact |

Introduction to Acrylic and Polypropylene Displays

Acrylic displays, made from polymethyl methacrylate, are renowned for their clarity, UV resistance, and durability, making them ideal for high-quality retail and promotional presentations. Polypropylene displays, crafted from a versatile thermoplastic polymer, offer cost-effective, lightweight, and chemical-resistant solutions suitable for short-term use or budget-conscious environments. Comparing both materials reveals acrylic's superior transparency and rigidity versus polypropylene's flexibility and affordability, guiding the choice based on display longevity and application requirements.

Material Composition: Acrylic vs Polypropylene

Acrylic displays are composed of polymethyl methacrylate (PMMA), offering superior clarity and rigidity compared to polypropylene, which is a thermoplastic polymer made from propylene monomers. Acrylic material provides better UV resistance and scratch resistance, making it ideal for long-term visual displays. Polypropylene displays are more flexible and impact-resistant but lack the optical clarity and hardness that acrylic offers.

Durability Comparison: Acrylic Display vs Polypropylene Display

Acrylic displays offer superior clarity and scratch resistance compared to polypropylene displays, making them ideal for long-term use in high-visibility settings. Polypropylene displays provide enhanced impact resistance and flexibility, which helps prevent cracking or breaking under stress. Choosing between acrylic and polypropylene displays depends on whether transparency and rigidity or durability against physical impact are prioritized.

Visual Clarity and Transparency

Acrylic displays offer superior visual clarity and higher transparency compared to polypropylene displays, making them ideal for showcasing products where clear visibility is crucial. Acrylic typically has a light transmittance rate of approximately 92%, resulting in less distortion and enhanced color fidelity. In contrast, polypropylene displays often exhibit a lower transparency level, around 85%, which can cause a slightly hazy appearance and reduce overall visual impact.

Weight and Handling Differences

Acrylic displays are heavier and more rigid compared to polypropylene displays, which are lightweight and flexible, enhancing portability and ease of handling. The density of acrylic, approximately 1.18 g/cm3, contributes to its sturdiness but can make it cumbersome for large or frequently moved displays. In contrast, polypropylene's lower density, around 0.90 g/cm3, offers superior maneuverability and reduced fatigue during setup or transport without compromising durability.

Customization and Design Flexibility

Acrylic displays offer superior customization and design flexibility compared to polypropylene displays due to their ease of machining, thermoforming, and polishing, enabling intricate shapes and high-gloss finishes. Acrylic's clarity and ability to be laser-etched or printed on provide enhanced aesthetic appeal and branding opportunities. Polypropylene displays, while more budget-friendly and impact-resistant, have limited design adaptability and often require simpler, less refined shapes.

Cost Efficiency: Which Is More Economical?

Acrylic displays generally offer a higher upfront cost compared to polypropylene displays, but their durability and clarity can provide long-term value in retail environments. Polypropylene displays are more economical initially due to lower material costs and ease of production, making them ideal for short-term or bulk display solutions. Choosing between the two depends on budget constraints and the display's intended longevity and visual impact.

Environmental Impact and Sustainability

Acrylic displays, known for their clarity and durability, are less environmentally friendly due to their reliance on non-biodegradable petroleum-based materials that contribute to long-term landfill waste. Polypropylene displays offer a more sustainable option with their recyclable nature and lower carbon footprint during production. Choosing polypropylene supports reduced environmental impact through easier recycling processes and greater resource efficiency.

Typical Applications for Each Material

Acrylic displays excel in high-end retail settings, museums, and art galleries due to their clarity, durability, and polished appearance, making them ideal for showcasing jewelry, electronics, and fine collectibles. Polypropylene displays are commonly used in grocery stores, promotional events, and point-of-purchase displays because of their lightweight nature, cost-effectiveness, and resistance to chemicals and moisture. Each material serves distinct roles: acrylic for long-term, aesthetically demanding presentations, and polypropylene for economical, flexible, and disposable display solutions.

Choosing the Right Display Material for Your Needs

Acrylic displays offer superior clarity and a high-gloss finish, making them ideal for showcasing products that require a sleek, professional appearance. Polypropylene displays provide greater flexibility and impact resistance, suitable for environments needing durable, lightweight solutions. Selecting the right display material depends on factors like aesthetic preference, durability requirements, and budget constraints.

Acrylic Display vs Polypropylene Display Infographic

materialdif.com

materialdif.com