Acrylic coating offers a clear, glossy finish that enhances color vibrancy and provides moderate protection against UV rays and weathering, making it ideal for decorative surfaces. Polyurethane coating delivers superior durability with excellent resistance to abrasion, chemicals, and moisture, ensuring long-lasting protection for high-traffic or industrial applications. Choosing between acrylic and polyurethane coatings depends on the balance needed between aesthetic appeal and robust protection for your acrylic pet projects.

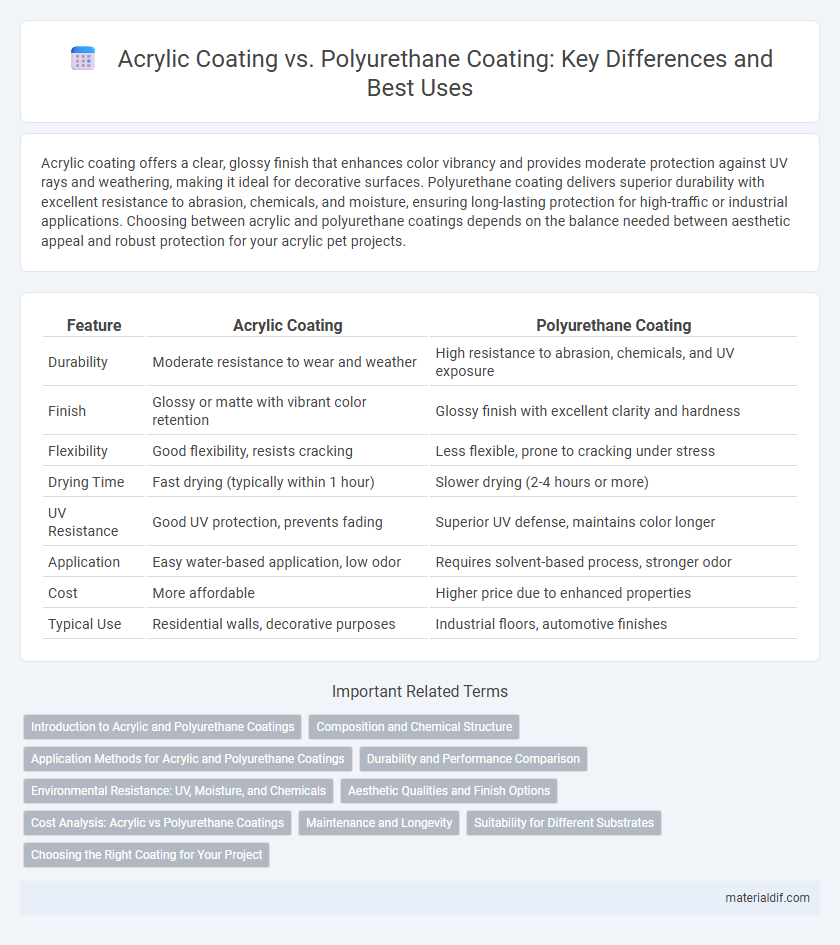

Table of Comparison

| Feature | Acrylic Coating | Polyurethane Coating |

|---|---|---|

| Durability | Moderate resistance to wear and weather | High resistance to abrasion, chemicals, and UV exposure |

| Finish | Glossy or matte with vibrant color retention | Glossy finish with excellent clarity and hardness |

| Flexibility | Good flexibility, resists cracking | Less flexible, prone to cracking under stress |

| Drying Time | Fast drying (typically within 1 hour) | Slower drying (2-4 hours or more) |

| UV Resistance | Good UV protection, prevents fading | Superior UV defense, maintains color longer |

| Application | Easy water-based application, low odor | Requires solvent-based process, stronger odor |

| Cost | More affordable | Higher price due to enhanced properties |

| Typical Use | Residential walls, decorative purposes | Industrial floors, automotive finishes |

Introduction to Acrylic and Polyurethane Coatings

Acrylic coatings are water-based, offering excellent UV resistance and color retention, making them ideal for exterior surfaces needing flexibility and breathability. Polyurethane coatings provide superior abrasion resistance and chemical durability due to their cross-linked polymer structure, suited for heavy-duty and industrial applications. Both coatings enhance surface protection but differ significantly in formulation, performance characteristics, and environmental adaptability.

Composition and Chemical Structure

Acrylic coating is primarily composed of acrylic polymers such as polymethyl methacrylate, characterized by ester functional groups that provide UV resistance and flexibility. Polyurethane coating contains urethane linkages formed from the reaction of isocyanates with polyols, resulting in a highly durable and chemically resistant polymer network. The chemical structure of acrylic coatings offers superior color retention, whereas polyurethane's molecular architecture delivers enhanced abrasion resistance and elasticity.

Application Methods for Acrylic and Polyurethane Coatings

Acrylic coatings are typically applied using brushes, rollers, or spray equipment, offering quick drying times that make them suitable for large surface areas and detailing alike. Polyurethane coatings require precise application through spraying or brushing, with more attention to controlled thickness and environmental conditions to ensure optimal cure and durability. Both coatings demand proper surface preparation, but polyurethane often necessitates stricter controls to avoid application defects such as runs or fisheyes.

Durability and Performance Comparison

Acrylic coatings exhibit excellent UV resistance and color retention but generally offer less abrasion and chemical resistance compared to polyurethane coatings. Polyurethane coatings provide superior durability with enhanced toughness, flexibility, and resistance to chemicals, solvents, and abrasion, making them ideal for high-traffic or demanding environments. While acrylic coatings are cost-effective and easier to apply, polyurethane coatings outperform in long-term wear and resilience under harsh conditions.

Environmental Resistance: UV, Moisture, and Chemicals

Acrylic coatings offer excellent UV resistance, maintaining color and gloss stability under prolonged sunlight exposure, making them ideal for outdoor applications. Polyurethane coatings excel in moisture resistance and chemical durability, providing superior protection against water penetration and harsh chemical environments. While acrylic coatings are more breathable and less prone to cracking, polyurethane coatings deliver a tougher, more flexible barrier for long-term environmental resilience.

Aesthetic Qualities and Finish Options

Acrylic coatings provide a vibrant, glossy finish that enhances color retention and resist yellowing, making them ideal for maintaining bright aesthetics. Polyurethane coatings offer a more durable, high-gloss or satin finish with superior chemical and abrasion resistance, suitable for high-traffic areas or surfaces requiring long-lasting protection. Choosing between acrylic and polyurethane coatings depends on the desired visual effect and the level of durability needed for the specific application.

Cost Analysis: Acrylic vs Polyurethane Coatings

Acrylic coatings typically offer a lower upfront cost compared to polyurethane coatings, making them a budget-friendly option for projects with tight financial constraints. Polyurethane coatings, while more expensive initially, provide superior durability and chemical resistance, potentially reducing long-term maintenance and replacement costs. Evaluating the total cost of ownership, including application, longevity, and performance, is crucial for determining the most cost-effective choice between acrylic and polyurethane coatings.

Maintenance and Longevity

Acrylic coatings offer easier maintenance due to their flexibility and UV resistance, making them ideal for surfaces exposed to sunlight. Polyurethane coatings provide superior durability and chemical resistance, resulting in longer lifespan, especially in high-traffic or industrial environments. Regular inspection and timely reapplication of either coating enhance overall longevity and maintain surface protection.

Suitability for Different Substrates

Acrylic coatings offer excellent adhesion and flexibility, making them well-suited for porous substrates such as wood, masonry, and concrete, where breathability and UV resistance are essential. Polyurethane coatings provide superior durability and chemical resistance, ideal for non-porous surfaces like metal and fiberglass that require strong abrasion protection and weathering performance. Choosing between acrylic and polyurethane coatings depends largely on the substrate's material properties and exposure conditions to optimize longevity and finish quality.

Choosing the Right Coating for Your Project

Acrylic coatings provide excellent UV resistance and flexibility, making them ideal for exterior surfaces exposed to sunlight and temperature fluctuations. Polyurethane coatings offer superior abrasion resistance and chemical durability, suited for high-traffic areas or industrial environments. Understanding project requirements such as exposure conditions, surface type, and desired longevity helps determine the most effective coating choice.

Acrylic Coating vs Polyurethane Coating Infographic

materialdif.com

materialdif.com