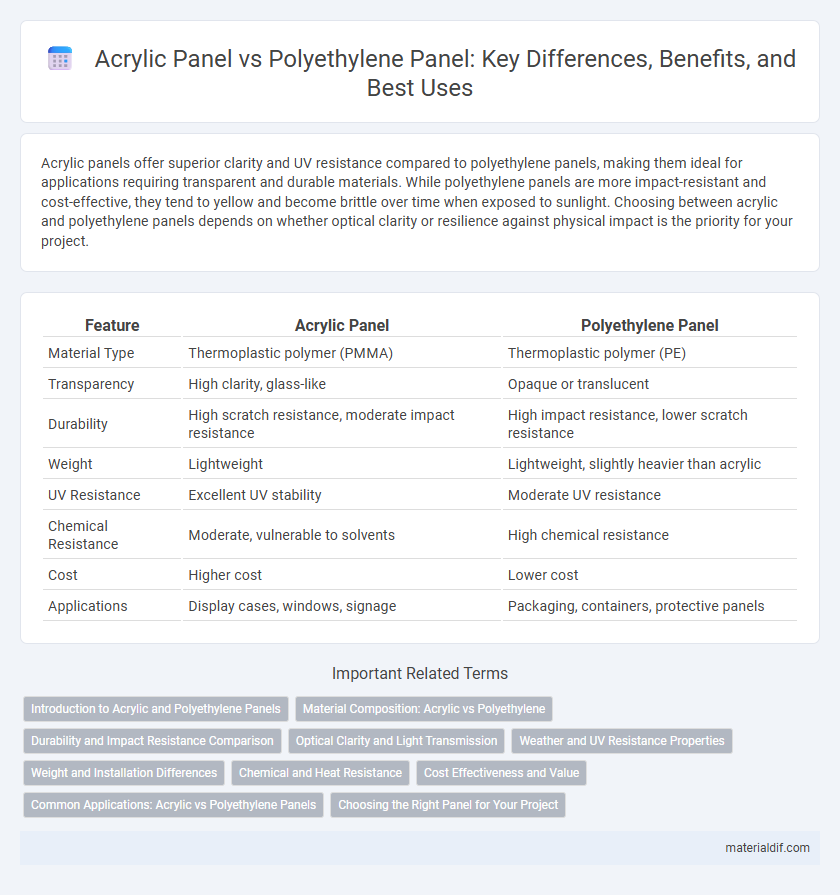

Acrylic panels offer superior clarity and UV resistance compared to polyethylene panels, making them ideal for applications requiring transparent and durable materials. While polyethylene panels are more impact-resistant and cost-effective, they tend to yellow and become brittle over time when exposed to sunlight. Choosing between acrylic and polyethylene panels depends on whether optical clarity or resilience against physical impact is the priority for your project.

Table of Comparison

| Feature | Acrylic Panel | Polyethylene Panel |

|---|---|---|

| Material Type | Thermoplastic polymer (PMMA) | Thermoplastic polymer (PE) |

| Transparency | High clarity, glass-like | Opaque or translucent |

| Durability | High scratch resistance, moderate impact resistance | High impact resistance, lower scratch resistance |

| Weight | Lightweight | Lightweight, slightly heavier than acrylic |

| UV Resistance | Excellent UV stability | Moderate UV resistance |

| Chemical Resistance | Moderate, vulnerable to solvents | High chemical resistance |

| Cost | Higher cost | Lower cost |

| Applications | Display cases, windows, signage | Packaging, containers, protective panels |

Introduction to Acrylic and Polyethylene Panels

Acrylic panels offer superior clarity, UV resistance, and weather durability, making them ideal for display and outdoor applications, while polyethylene panels provide excellent impact resistance and chemical stability often used in industrial and packaging settings. Acrylic panels are rigid and lightweight with a glass-like appearance, whereas polyethylene panels are more flexible and opaque. The choice between acrylic and polyethylene panels depends on the specific requirements for transparency, toughness, and environmental exposure.

Material Composition: Acrylic vs Polyethylene

Acrylic panels, composed of polymethyl methacrylate (PMMA), exhibit superior optical clarity and UV resistance compared to polyethylene panels, which are made from polymerized ethylene. Acrylic's rigid molecular structure provides enhanced durability and scratch resistance, while polyethylene offers greater flexibility and impact resistance due to its branched hydrocarbon chains. These distinct material compositions directly influence the applications, with acrylic preferred for transparent, high-strength uses and polyethylene favored for more flexible, impact-tolerant solutions.

Durability and Impact Resistance Comparison

Acrylic panels exhibit superior clarity and weather resistance but have lower impact resistance compared to polyethylene panels, which offer excellent toughness and flexibility. While acrylic panels may crack under high impact, polyethylene panels are more durable against physical stress and less prone to shattering. This makes polyethylene panels a preferred choice for applications requiring high impact resistance and long-term durability in harsh environments.

Optical Clarity and Light Transmission

Acrylic panels offer superior optical clarity compared to polyethylene panels, providing a clearer and more transparent surface ideal for applications requiring high visibility. With light transmission rates up to 92%, acrylic outperforms polyethylene, which generally transmits around 80% of visible light. This makes acrylic panels the preferred choice for display cases, windows, and lighting fixtures where maximum clarity and brightness are essential.

Weather and UV Resistance Properties

Acrylic panels exhibit superior weather and UV resistance compared to polyethylene panels, maintaining clarity and structural integrity under prolonged sun exposure and harsh outdoor conditions. Unlike polyethylene, acrylic resists yellowing and becomes less brittle, ensuring long-term durability and aesthetic appeal in outdoor applications. These properties make acrylic panels a preferred choice for signage, glazing, and protective coverings exposed to varying weather elements.

Weight and Installation Differences

Acrylic panels are significantly lighter than polyethylene panels, enhancing ease of handling and reducing installation time. Acrylic's rigidity allows for straightforward cutting and drilling without compromising structural integrity, while polyethylene panels often require specialized tools due to their flexibility. The lower weight and easier installation process of acrylic panels make them ideal for applications where quick and efficient assembly is crucial.

Chemical and Heat Resistance

Acrylic panels exhibit superior chemical resistance against acids, alkalis, and solvents compared to polyethylene panels, making them ideal for environments with exposure to harsh chemicals. Acrylic maintains structural integrity and clarity at higher temperatures, with a heat deflection temperature around 100degC, whereas polyethylene panels generally melt or deform at temperatures above 80degC. This enhanced thermal and chemical stability makes acrylic panels preferable for applications requiring durability under heat and chemical exposure.

Cost Effectiveness and Value

Acrylic panels typically offer higher clarity and durability compared to polyethylene panels, making them a more cost-effective choice for long-term applications despite a slightly higher upfront cost. Polyethylene panels are usually less expensive initially but may require more frequent replacement due to lower resistance to scratches and UV damage. Evaluating the value depends on the project's need for longevity and visual appeal, where acrylic panels often provide better overall investment through durability and aesthetic quality.

Common Applications: Acrylic vs Polyethylene Panels

Acrylic panels are widely used in applications requiring clarity and aesthetic appeal such as signage, display cases, and windows due to their transparency and UV resistance. Polyethylene panels excel in packaging, protective barriers, and construction where impact resistance and chemical durability are prioritized. Both materials serve distinct roles based on environmental exposure and mechanical requirements.

Choosing the Right Panel for Your Project

Acrylic panels offer superior clarity, UV resistance, and impact strength compared to polyethylene panels, making them ideal for applications requiring durability and visual appeal. Polyethylene panels boast higher chemical resistance and flexibility, suitable for environments exposed to harsh chemicals or requiring lightweight materials. Selecting the right panel depends on balancing optical quality, environmental exposure, and mechanical demands specific to your project's needs.

Acrylic Panel vs Polyethylene Panel Infographic

materialdif.com

materialdif.com