Acrylic glass offers superior impact resistance compared to regular glass, making it more durable and less prone to shattering. Its lightweight nature enhances ease of handling and installation, while maintaining excellent transparency similar to glass. Acrylic glass also provides better resistance to UV light, reducing yellowing and extending its lifespan in outdoor applications.

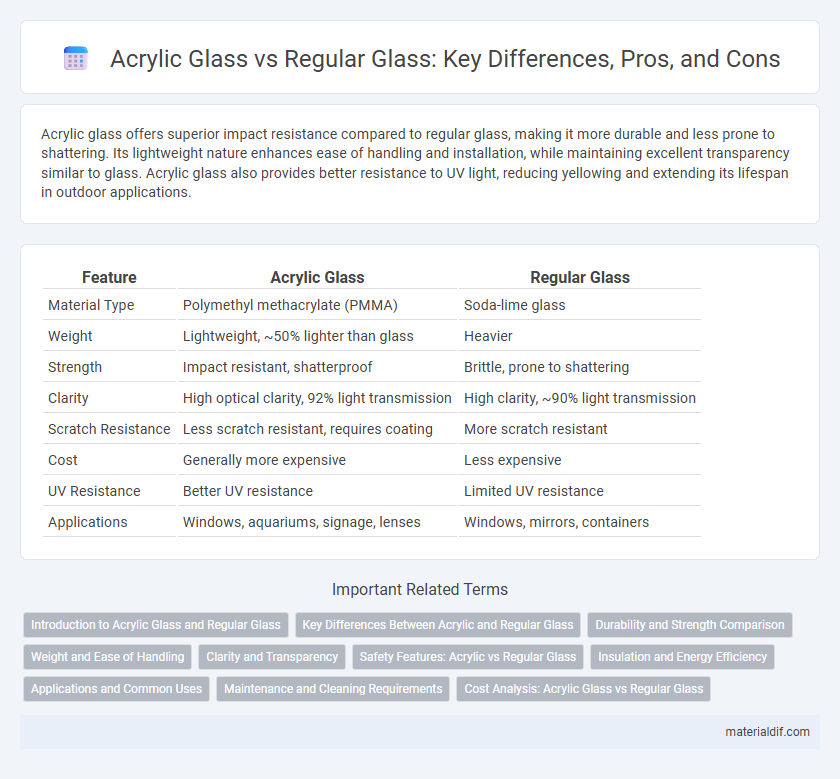

Table of Comparison

| Feature | Acrylic Glass | Regular Glass |

|---|---|---|

| Material Type | Polymethyl methacrylate (PMMA) | Soda-lime glass |

| Weight | Lightweight, ~50% lighter than glass | Heavier |

| Strength | Impact resistant, shatterproof | Brittle, prone to shattering |

| Clarity | High optical clarity, 92% light transmission | High clarity, ~90% light transmission |

| Scratch Resistance | Less scratch resistant, requires coating | More scratch resistant |

| Cost | Generally more expensive | Less expensive |

| UV Resistance | Better UV resistance | Limited UV resistance |

| Applications | Windows, aquariums, signage, lenses | Windows, mirrors, containers |

Introduction to Acrylic Glass and Regular Glass

Acrylic glass, also known as polymethyl methacrylate (PMMA), is a lightweight, shatter-resistant material commonly used as a substitute for regular glass. Regular glass, primarily made from silica, offers excellent clarity but is heavier and more prone to breaking upon impact. Acrylic glass provides superior impact resistance and UV stability, making it ideal for applications requiring durability and safety.

Key Differences Between Acrylic and Regular Glass

Acrylic glass, also known as plexiglass, is significantly lighter and more impact-resistant than regular glass, making it ideal for applications requiring durability and safety. While regular glass offers superior scratch resistance and clarity, acrylic provides better flexibility and UV resistance, reducing the risk of shattering. The manufacturing process of acrylic involves polymerization of methyl methacrylate, resulting in a material that is easier to shape and cut compared to the brittle nature of traditional soda-lime glass.

Durability and Strength Comparison

Acrylic glass offers superior durability and impact resistance compared to regular glass, making it less prone to shattering under stress. While regular glass can easily crack or break upon impact, acrylic glass maintains its structural integrity due to its flexible composition. This strength advantage highlights acrylic as the preferred choice for applications requiring enhanced safety and longevity.

Weight and Ease of Handling

Acrylic glass is significantly lighter than regular glass, weighing approximately half as much, which enhances ease of handling and reduces shipping costs. Its impact resistance is up to 17 times greater than that of standard glass, making it less prone to breakage and safer to transport and install. These properties make acrylic glass a preferred material for applications requiring durability and lightweight characteristics, such as display cases and protective barriers.

Clarity and Transparency

Acrylic glass offers superior clarity and transparency compared to regular glass, boasting light transmittance of approximately 92% versus glass's 86-90%. Its molecular structure reduces internal reflections, resulting in a clearer and brighter appearance. Acrylic also resists yellowing over time, maintaining optical clarity longer than traditional glass.

Safety Features: Acrylic vs Regular Glass

Acrylic glass offers superior safety features compared to regular glass due to its impact resistance, which is up to 17 times greater, reducing the risk of shattering and injury. Unlike regular glass that can break into sharp shards, acrylic glass cracks under extreme stress but maintains structural integrity, minimizing hazards. This makes acrylic an ideal choice for environments requiring enhanced safety, such as schools, hospitals, and sports facilities.

Insulation and Energy Efficiency

Acrylic glass offers superior insulation properties compared to regular glass, with a thermal conductivity of around 0.19 W/m*K, significantly lower than the 1.0 W/m*K typical of standard glass. This enhanced insulation reduces heat transfer, leading to better energy efficiency in buildings by maintaining indoor temperatures and lowering heating and cooling costs. Its lightweight and impact-resistant nature also contributes to long-term energy savings by minimizing damage and replacement needs.

Applications and Common Uses

Acrylic glass, also known as PMMA, is widely used in automotive, aerospace, and signage industries due to its lightweight, impact resistance, and excellent optical clarity, outperforming regular glass in safety and durability. Common applications include display cases, skylights, protective barriers, and aquariums, where shatterproof and UV-resistant properties are crucial. Regular glass remains preferred for windows, mirrors, and architectural facades where scratch resistance and heat tolerance are more critical.

Maintenance and Cleaning Requirements

Acrylic glass requires less maintenance than regular glass due to its superior resistance to shattering and scratching, making it ideal for high-traffic areas. It cleans easily with mild soap and water, avoiding abrasive cleaners that can cause surface damage. Regular glass demands more careful handling to prevent chips and cracks and often requires specialized glass cleaners to maintain its clarity and shine.

Cost Analysis: Acrylic Glass vs Regular Glass

Acrylic glass typically costs between $10 to $20 per square foot, making it more affordable than regular glass, which ranges from $15 to $30 per square foot depending on thickness and type. The lower weight of acrylic reduces handling and installation expenses, further enhancing cost efficiency. Despite higher initial durability, acrylic may require more frequent replacement due to scratching compared to tempered glass, impacting long-term maintenance costs.

Acrylic Glass vs Regular Glass Infographic

materialdif.com

materialdif.com