Acrylic polishing produces a smooth, clear surface by using abrasive compounds and buffing wheels, making it ideal for intricate shapes and delicate edges. Flame polishing applies controlled heat to melt the acrylic surface slightly, resulting in a glossy finish but with the risk of warping or distortion on thin or complex parts. Choosing between acrylic polishing and flame polishing depends on the desired finish quality and the specific shape and thickness of the acrylic piece.

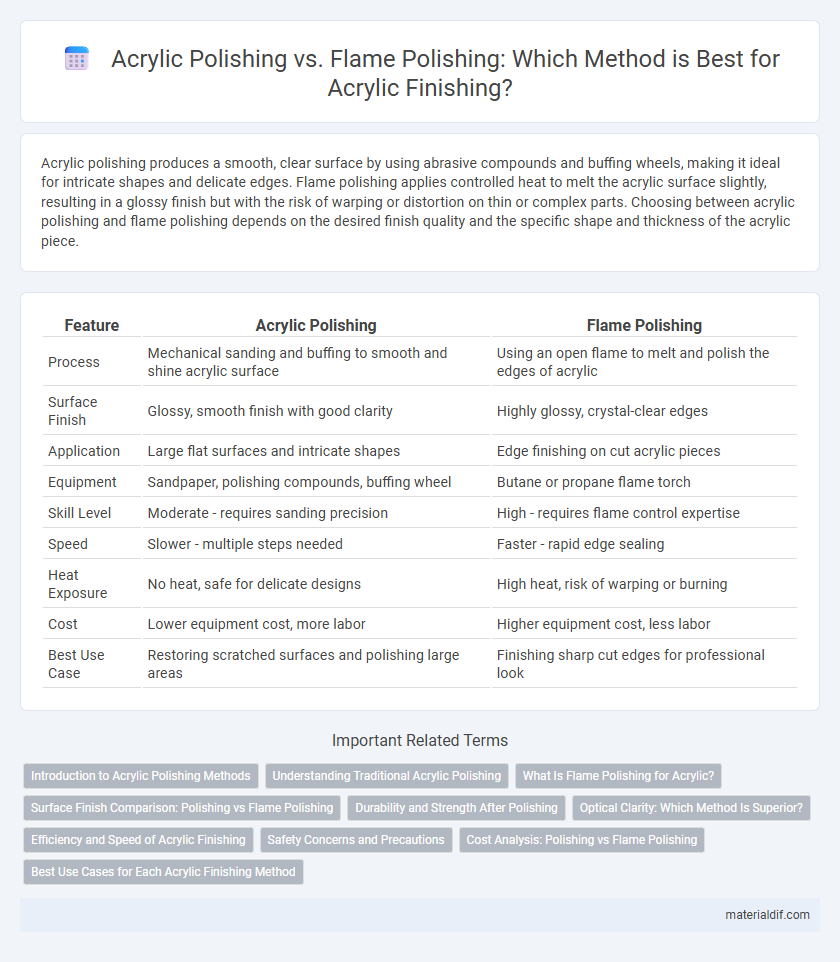

Table of Comparison

| Feature | Acrylic Polishing | Flame Polishing |

|---|---|---|

| Process | Mechanical sanding and buffing to smooth and shine acrylic surface | Using an open flame to melt and polish the edges of acrylic |

| Surface Finish | Glossy, smooth finish with good clarity | Highly glossy, crystal-clear edges |

| Application | Large flat surfaces and intricate shapes | Edge finishing on cut acrylic pieces |

| Equipment | Sandpaper, polishing compounds, buffing wheel | Butane or propane flame torch |

| Skill Level | Moderate - requires sanding precision | High - requires flame control expertise |

| Speed | Slower - multiple steps needed | Faster - rapid edge sealing |

| Heat Exposure | No heat, safe for delicate designs | High heat, risk of warping or burning |

| Cost | Lower equipment cost, more labor | Higher equipment cost, less labor |

| Best Use Case | Restoring scratched surfaces and polishing large areas | Finishing sharp cut edges for professional look |

Introduction to Acrylic Polishing Methods

Acrylic polishing methods primarily include mechanical polishing and flame polishing, each offering distinct finishes and applications. Mechanical polishing uses abrasive compounds and buffing wheels to smooth surfaces, ideal for intricate shapes and minor scratches. Flame polishing employs a controlled propane or butane flame to melt the acrylic surface, resulting in a high-gloss, crystal-clear finish commonly used for flat or slightly curved edges.

Understanding Traditional Acrylic Polishing

Traditional acrylic polishing involves using abrasive materials or compounds to smooth and enhance the surface of acrylic sheets, restoring clarity and removing scratches. This method requires careful manual or mechanical application of polishing compounds with buffing wheels or cloths, providing precision in finishing edges and surfaces. Unlike flame polishing, which uses heat to create a glossy surface, traditional polishing maintains the acrylic's structural integrity without the risk of warping or melting.

What Is Flame Polishing for Acrylic?

Flame polishing for acrylic involves using a controlled flame to gently melt the surface, resulting in a smooth, glossy finish that restores clarity and removes scratches. This technique is ideal for edges and curved surfaces where mechanical abrasion is difficult, providing a seamless, transparent look without additional polishing compounds. Compared to traditional acrylic polishing methods, flame polishing is faster and creates a durable, highly reflective surface that enhances the overall appearance of acrylic products.

Surface Finish Comparison: Polishing vs Flame Polishing

Acrylic polishing produces a smooth, glossy surface by mechanically buffing scratches and imperfections, resulting in a highly reflective finish ideal for display cases and signage. Flame polishing uses a controlled gas flame to slightly melt the acrylic surface, creating a near-perfect, glass-like clarity that enhances transparency and reduces light diffusion. While polishing offers precise control over surface texture, flame polishing achieves superior optical clarity and a more seamless, high-gloss appearance on acrylic edges and curved surfaces.

Durability and Strength After Polishing

Acrylic polishing methods significantly impact the material's durability and strength, with flame polishing creating a seamless, glossy finish by melting the surface, which can enhance the acrylic's structural integrity by reducing micro-cracks. In contrast, mechanical acrylic polishing removes scratches through abrasion but may weaken edges due to material removal, potentially making the acrylic more prone to future damage. Flame polishing is generally preferred for preserving acrylic strength and offering superior durability in high-stress applications.

Optical Clarity: Which Method Is Superior?

Flame polishing provides superior optical clarity for acrylic surfaces by melting the plastic's edges to create a smooth, glass-like finish that minimizes light distortion. In contrast, acrylic polishing relies on mechanical abrasion and buffing, which can leave micro-scratches that slightly reduce transparency and gloss. For applications requiring maximum visual clarity, such as display cases and lenses, flame polishing is the preferred method due to its enhanced clarity and sleek surface quality.

Efficiency and Speed of Acrylic Finishing

Acrylic polishing delivers a smooth, clear finish by using abrasives and polishing compounds, offering precise control over surface quality but typically requiring more time and effort. Flame polishing uses a high-temperature flame to melt the acrylic surface, providing a faster and more efficient method for achieving glossy finishes on flat or gently curved surfaces. While flame polishing excels in speed and efficiency for large or simple shapes, acrylic polishing remains superior for intricate details and areas needing meticulous surface refinement.

Safety Concerns and Precautions

Acrylic polishing involves using abrasive compounds and polishing wheels, which require proper ventilation and protective gear to avoid inhalation of fine particles and skin irritation. Flame polishing uses a high-temperature flame to melt the acrylic surface, creating potential risks of burns, toxic fumes, and fire hazards, necessitating strict flame control and use of heat-resistant gloves and eye protection. Both methods demand adherence to safety protocols, including working in well-ventilated areas and wearing appropriate personal protective equipment to minimize health risks.

Cost Analysis: Polishing vs Flame Polishing

Acrylic polishing typically incurs lower costs due to minimal equipment requirements and quicker processing times compared to flame polishing, which demands specialized torches and skilled operators. Flame polishing increases expenses from higher energy consumption and safety measures, impacting overall project budgets. Choosing between these methods depends on balancing cost efficiency with desired surface quality and production scale.

Best Use Cases for Each Acrylic Finishing Method

Acrylic polishing is ideal for restoring clarity and removing scratches on flat or gently curved surfaces, making it suitable for display cases, picture frames, and aquariums. Flame polishing is best for finishing complex edges and curved shapes, providing a smooth, glossy finish often used in automotive parts and artistic acrylic sculptures. Choosing between these methods depends on the acrylic piece's shape and desired surface quality, with polishing preferred for precision and flame polishing for aesthetics on intricate contours.

Acrylic Polishing vs Flame Polishing Infographic

materialdif.com

materialdif.com