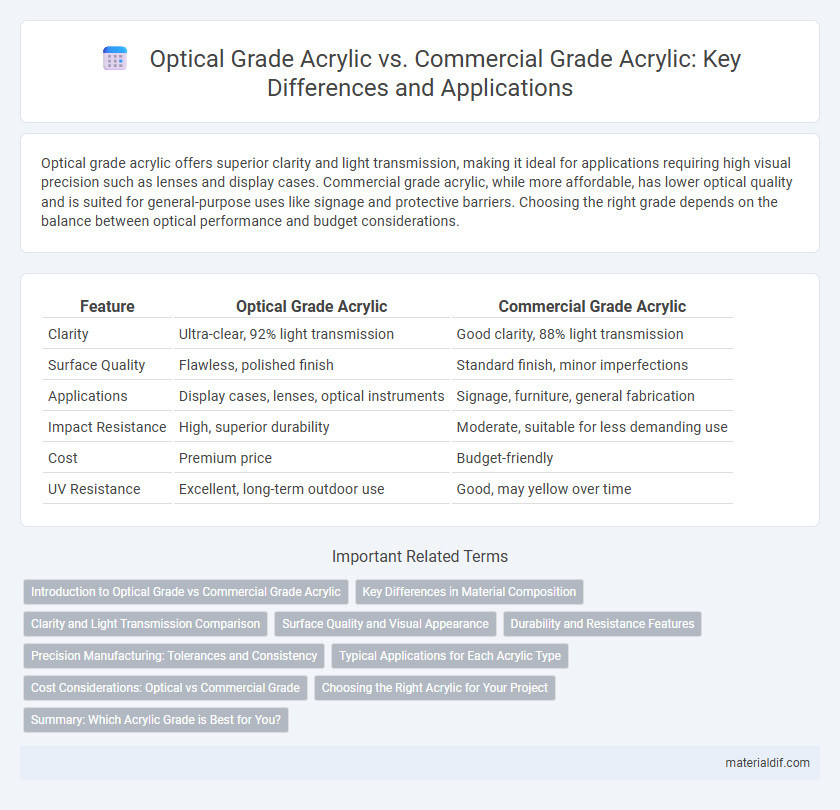

Optical grade acrylic offers superior clarity and light transmission, making it ideal for applications requiring high visual precision such as lenses and display cases. Commercial grade acrylic, while more affordable, has lower optical quality and is suited for general-purpose uses like signage and protective barriers. Choosing the right grade depends on the balance between optical performance and budget considerations.

Table of Comparison

| Feature | Optical Grade Acrylic | Commercial Grade Acrylic |

|---|---|---|

| Clarity | Ultra-clear, 92% light transmission | Good clarity, 88% light transmission |

| Surface Quality | Flawless, polished finish | Standard finish, minor imperfections |

| Applications | Display cases, lenses, optical instruments | Signage, furniture, general fabrication |

| Impact Resistance | High, superior durability | Moderate, suitable for less demanding use |

| Cost | Premium price | Budget-friendly |

| UV Resistance | Excellent, long-term outdoor use | Good, may yellow over time |

Introduction to Optical Grade vs Commercial Grade Acrylic

Optical grade acrylic offers superior light transmission of up to 92% and exceptional clarity compared to commercial grade acrylic, which typically has lower transparency and more impurities. Manufactured with stringent quality control for minimal defects and high uniformity, optical grade acrylic is ideal for precision applications such as lenses and display panels. Commercial grade acrylic, while more cost-effective, suits general purposes where optical performance is less critical.

Key Differences in Material Composition

Optical grade acrylic is formulated with higher purity monomers and fewer additives, resulting in superior clarity and light transmittance above 92%, ideal for precision optical applications. Commercial grade acrylic contains more stabilizers and colorants that enhance durability but reduce transparency to around 85-90%, making it suitable for general-purpose uses. The molecular weight distribution in optical grade acrylic is more uniform, contributing to its enhanced optical properties compared to the broader, less consistent polymer chains found in commercial grade variants.

Clarity and Light Transmission Comparison

Optical grade acrylic exhibits superior clarity with light transmission rates up to 92%, making it ideal for applications requiring high optical performance. Commercial grade acrylic typically offers lower clarity and reduced light transmission, around 85-88%, due to increased impurities and less refined manufacturing processes. The enhanced transparency of optical grade acrylic ensures minimal distortion and excellent visual acuity in lenses, displays, and lighting fixtures.

Surface Quality and Visual Appearance

Optical Grade Acrylic offers superior surface quality with exceptional clarity, minimal distortion, and high light transmittance of up to 92%, making it ideal for precision optical applications. In contrast, Commercial Grade Acrylic exhibits lower surface finish standards, often containing minor imperfections and reduced transparency, resulting in less visual clarity. The enhanced visual appearance and scratch resistance of Optical Grade Acrylic ensure optimal performance in demanding environments requiring flawless optical properties.

Durability and Resistance Features

Optical grade acrylic offers superior durability and scratch resistance compared to commercial grade acrylic, making it ideal for precision lenses and optical applications. Its enhanced clarity and UV resistance prevent yellowing and degradation over time, maintaining performance in harsh environmental conditions. Commercial grade acrylic, while more cost-effective, has lower resistance to impact and abrasions, reducing its lifespan in high-stress or outdoor uses.

Precision Manufacturing: Tolerances and Consistency

Optical grade acrylic is manufactured with extremely tight tolerances, ensuring exceptional surface flatness and uniform thickness critical for high-precision optical applications such as lenses and light guides. Commercial grade acrylic offers broader tolerance ranges, which is suitable for general-purpose uses but lacks the consistency required for precision light transmission or imaging. The precision manufacturing process for optical grade acrylic involves rigorous quality control to maintain clarity and minimal distortion, whereas commercial grade acrylic prioritizes cost-efficiency over exact dimensional consistency.

Typical Applications for Each Acrylic Type

Optical grade acrylic is commonly used in applications requiring superior clarity and light transmission, such as lenses, display cases, and optical instruments. Commercial grade acrylic finds its applications in signage, protective barriers, and general-purpose glazing where durability and cost-effectiveness are prioritized over optical clarity. The distinct material properties dictate their suitability for high-precision optical uses versus everyday structural and decorative functions.

Cost Considerations: Optical vs Commercial Grade

Optical grade acrylic commands higher prices due to its superior clarity, enhanced light transmission, and minimal impurities, making it ideal for precision optical applications and high-end displays. Commercial grade acrylic is more cost-effective, providing adequate durability and visual quality for general use in signage, enclosures, and furniture where optical perfection is less critical. Budget allocations should consider the required optical performance and intended application, balancing cost savings against the necessity for premium visual clarity and strength.

Choosing the Right Acrylic for Your Project

Optical grade acrylic offers superior clarity with light transmittance up to 92%, making it ideal for precision applications such as lenses and display covers, while commercial grade acrylic provides a more cost-effective solution with slightly lower clarity, suitable for general-purpose uses like signage and furniture. The choice depends on the importance of optical performance versus budget constraints, with optical grade acrylic ensuring minimal distortion and commercial grade acrylic delivering durability at a lower cost. Assess project requirements for transparency, surface finish, and mechanical strength to select the appropriate acrylic type that balances quality and affordability.

Summary: Which Acrylic Grade is Best for You?

Optical Grade Acrylic offers superior clarity, low optical distortion, and high light transmission, making it ideal for applications requiring precision and visual excellence such as lenses, displays, and lighting fixtures. Commercial Grade Acrylic provides good durability and versatility at a lower cost, suitable for general-purpose uses like signage, frames, and protective barriers. Choose Optical Grade for premium optical performance and Commercial Grade for budget-friendly, everyday applications.

Optical Grade Acrylic vs Commercial Grade Acrylic Infographic

materialdif.com

materialdif.com