Acrylic laminate offers superior gloss and a more vibrant, high-end finish compared to HPL laminate, making it ideal for modern interior designs. It also provides better resistance to scratches and UV rays, ensuring long-lasting durability and color retention. While HPL laminate is generally more budget-friendly, acrylic laminate's enhanced aesthetic appeal and durability justify its higher investment for premium applications.

Table of Comparison

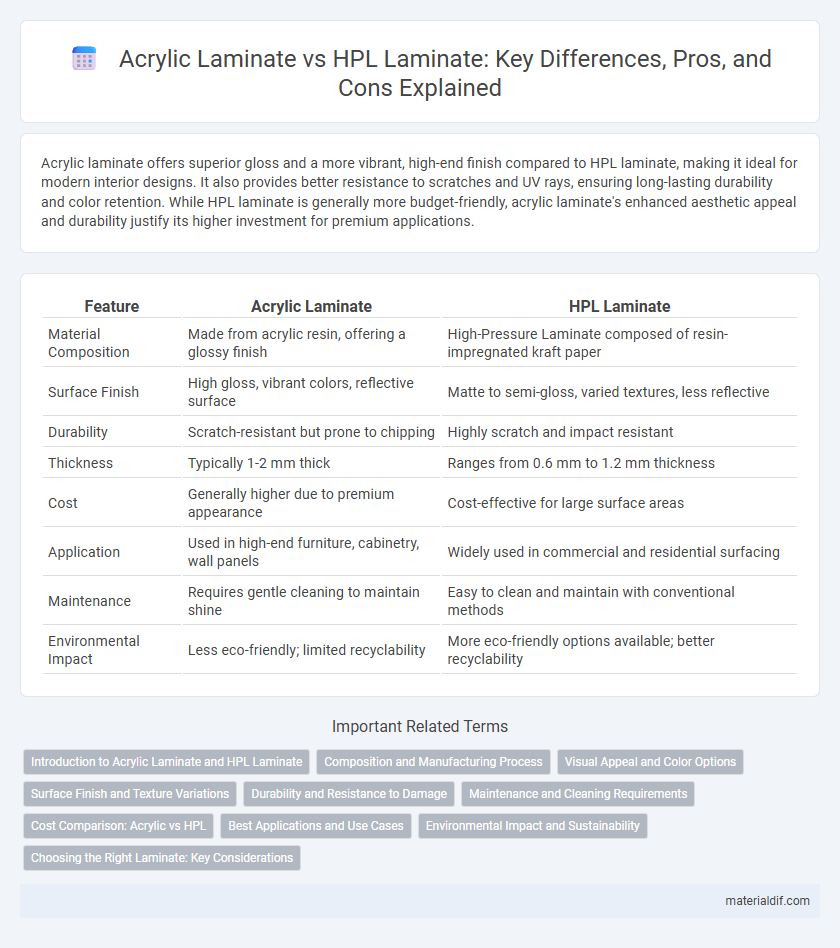

| Feature | Acrylic Laminate | HPL Laminate |

|---|---|---|

| Material Composition | Made from acrylic resin, offering a glossy finish | High-Pressure Laminate composed of resin-impregnated kraft paper |

| Surface Finish | High gloss, vibrant colors, reflective surface | Matte to semi-gloss, varied textures, less reflective |

| Durability | Scratch-resistant but prone to chipping | Highly scratch and impact resistant |

| Thickness | Typically 1-2 mm thick | Ranges from 0.6 mm to 1.2 mm thickness |

| Cost | Generally higher due to premium appearance | Cost-effective for large surface areas |

| Application | Used in high-end furniture, cabinetry, wall panels | Widely used in commercial and residential surfacing |

| Maintenance | Requires gentle cleaning to maintain shine | Easy to clean and maintain with conventional methods |

| Environmental Impact | Less eco-friendly; limited recyclability | More eco-friendly options available; better recyclability |

Introduction to Acrylic Laminate and HPL Laminate

Acrylic laminate is a high-gloss surface material known for its superior clarity, durability, and resistance to UV rays, making it ideal for modern interior applications that demand a sleek, reflective finish. HPL laminate, or High-Pressure Laminate, is manufactured by bonding multiple layers of kraft paper and resin under high heat and pressure, resulting in a dense, highly durable surface suited for high-traffic areas. Both acrylic and HPL laminates offer robust performance, but acrylic's scratch resistance and vibrant colors make it preferred for luxury cabinetry, while HPL excels in cost-effectiveness and versatility for commercial environments.

Composition and Manufacturing Process

Acrylic laminate is composed primarily of a solid acrylic resin layer bonded to a substrate, offering a high-gloss, scratch-resistant finish achieved through a curing process involving UV light or heat. HPL laminate consists of multiple layers of kraft paper impregnated with phenolic resin, topped with a decorative layer saturated with melamine resin, which are assembled under high heat and pressure to create a durable, impact-resistant surface. The acrylic manufacturing process emphasizes clarity and smoothness, while HPL production focuses on layering and compressing materials to ensure robustness and design versatility.

Visual Appeal and Color Options

Acrylic laminate offers a high-gloss, mirror-like finish with vibrant, consistent colors that resist fading, making it ideal for modern, sleek designs. HPL laminate provides a wider variety of patterns and textures, including wood grains and stone effects, but often with a matte or semi-gloss finish that lacks acrylic's depth and brilliance. The superior color retention and reflective quality of acrylic laminate make it a preferred choice for projects demanding strong visual impact and long-lasting aesthetic appeal.

Surface Finish and Texture Variations

Acrylic laminate offers a high-gloss, mirror-like surface finish that enhances depth and color vibrancy, making it ideal for modern interiors requiring sleek aesthetics. HPL laminate provides a broader range of texture variations, including matte, textured, and woodgrain finishes, allowing versatility in tactile experience and design customization. While acrylic excels in premium gloss and smoothness, HPL is preferred for its durability and diverse surface textures suitable for high-traffic areas.

Durability and Resistance to Damage

Acrylic laminate offers superior durability due to its high impact resistance and ability to maintain a glossy finish without yellowing over time, making it ideal for areas prone to frequent use. HPL (High-Pressure Laminate) laminate provides strong resistance to scratches, heat, and moisture, ensuring long-lasting protection against everyday wear and tear. Both materials excel in damage resistance, but acrylic laminate's enhanced surface hardness and UV stability typically result in better longevity and aesthetic retention.

Maintenance and Cleaning Requirements

Acrylic laminate offers a smooth, non-porous surface that resists stains and requires only mild soap and water for regular cleaning, reducing maintenance efforts compared to HPL laminate. HPL laminate, while durable, can be more prone to scratches and requires specialized cleaners to avoid surface damage and maintain its appearance. Both materials benefit from prompt spill cleanup, but acrylic's superior resistance to chemicals and abrasion makes it easier to maintain long-term gloss and hygiene.

Cost Comparison: Acrylic vs HPL

Acrylic laminate typically costs 20-30% more than HPL (High-Pressure Laminate) due to its superior glossy finish and scratch resistance. HPL laminate remains a budget-friendly option, favored for its durability and variety of design choices at lower prices. Choosing between acrylic and HPL hinges on budget constraints and desired aesthetics, with acrylic offering a premium look while HPL prioritizes cost-effectiveness.

Best Applications and Use Cases

Acrylic laminate offers superior gloss, scratch resistance, and depth, making it ideal for high-end furniture, kitchen cabinets, and retail displays requiring a luxurious finish. HPL laminate excels in durability, impact resistance, and cost-effectiveness, suitable for commercial environments, countertops, and high-traffic areas. Choosing between acrylic and HPL depends on balancing aesthetic appeal with functional demands in residential or commercial applications.

Environmental Impact and Sustainability

Acrylic laminate offers higher durability and longer lifespan, reducing replacement frequency and associated waste, while being recyclable under specific conditions. HPL (High-Pressure Laminate) is generally produced using more energy-intensive processes and contains phenolic resins that can off-gas volatile organic compounds (VOCs), impacting indoor air quality and environmental health. Sustainable sourcing and end-of-life management play critical roles in minimizing the ecological footprint of both materials, with acrylic laminates often favored for their lower emissions and potential for eco-friendly recycling programs.

Choosing the Right Laminate: Key Considerations

Acrylic laminate offers superior gloss and scratch resistance, making it ideal for high-end cabinetry and furniture requiring durable, reflective surfaces. HPL laminate excels in cost-effectiveness and impact resistance, suitable for commercial applications with heavy usage and diverse design options. Selecting the right laminate depends on factors such as budget, aesthetic preference, durability needs, and the specific environment where the laminate will be applied.

Acrylic Laminate vs HPL Laminate Infographic

materialdif.com

materialdif.com