Acrylic tubing offers superior clarity and UV resistance compared to PVC tubing, making it ideal for applications requiring high transparency and durability. While PVC tubing is generally more flexible and cost-effective, it lacks the rigidity and scratch resistance of acrylic, which can be crucial for long-term use. Acrylic's chemical resistance and ease of fabrication provide enhanced performance in environments where aesthetic appearance and strength are priorities.

Table of Comparison

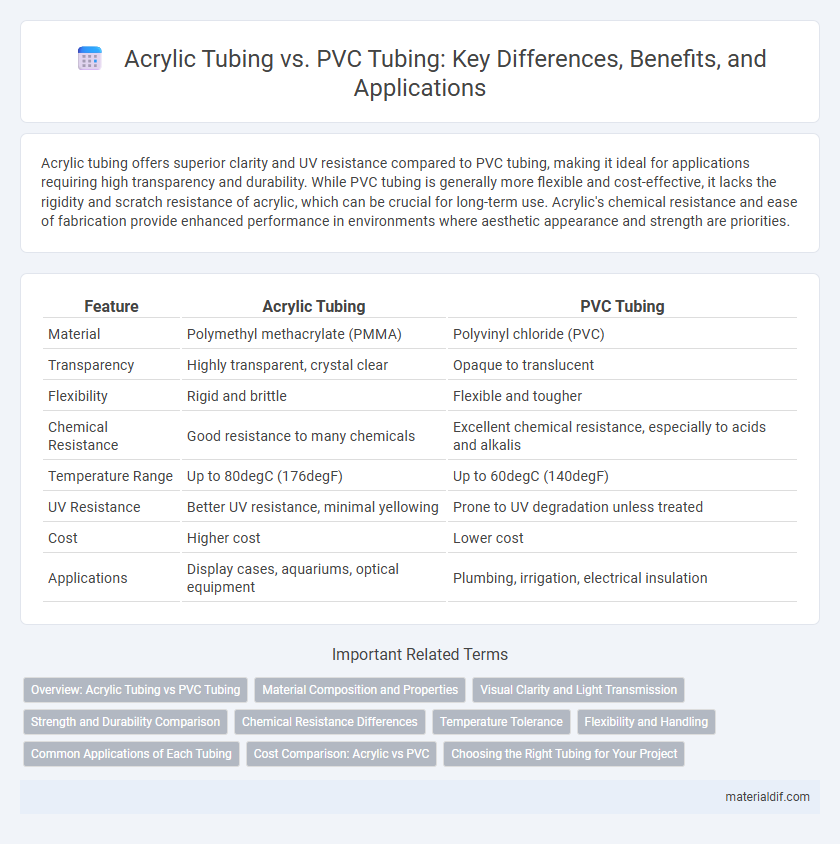

| Feature | Acrylic Tubing | PVC Tubing |

|---|---|---|

| Material | Polymethyl methacrylate (PMMA) | Polyvinyl chloride (PVC) |

| Transparency | Highly transparent, crystal clear | Opaque to translucent |

| Flexibility | Rigid and brittle | Flexible and tougher |

| Chemical Resistance | Good resistance to many chemicals | Excellent chemical resistance, especially to acids and alkalis |

| Temperature Range | Up to 80degC (176degF) | Up to 60degC (140degF) |

| UV Resistance | Better UV resistance, minimal yellowing | Prone to UV degradation unless treated |

| Cost | Higher cost | Lower cost |

| Applications | Display cases, aquariums, optical equipment | Plumbing, irrigation, electrical insulation |

Overview: Acrylic Tubing vs PVC Tubing

Acrylic tubing offers superior clarity and UV resistance compared to PVC tubing, making it ideal for applications requiring transparency and aesthetic appeal. PVC tubing is more flexible, chemical-resistant, and cost-effective, suitable for industrial and plumbing uses where durability and affordability are prioritized. Both materials serve distinct purposes, with acrylic excelling in visual performance and PVC favored for practical, robust applications.

Material Composition and Properties

Acrylic tubing is composed of polymethyl methacrylate (PMMA), offering exceptional optical clarity, high impact resistance, and superior UV stability compared to PVC tubing, which is made from polyvinyl chloride with moderate clarity and flexibility but greater chemical resistance. Acrylic tubing provides rigid structural integrity and excellent weatherability, making it ideal for applications requiring transparency and aesthetics. In contrast, PVC tubing is more versatile in harsh chemical environments but lacks the optical transparency and crisp finish characteristic of acrylic.

Visual Clarity and Light Transmission

Acrylic tubing offers superior visual clarity and light transmission compared to PVC tubing, with light transmittance rates of up to 92%, making it ideal for applications requiring high transparency. PVC tubing typically has a lower light transmittance, around 85%, and may appear slightly cloudy or tinted, which can reduce visibility in lighting or display uses. The enhanced optical properties of acrylic make it the preferred choice for aesthetic and lighting applications where clear, bright results are essential.

Strength and Durability Comparison

Acrylic tubing offers superior impact resistance and maintains clarity over time, making it highly durable compared to PVC tubing, which is more prone to cracking under stress. PVC tubing, while flexible and resistant to chemicals, tends to degrade faster when exposed to UV light and extreme temperatures. For applications demanding long-lasting strength and transparency, acrylic tubing is generally the preferred choice.

Chemical Resistance Differences

Acrylic tubing offers excellent resistance to many chemicals, including acids and alkalis, but it is susceptible to attack by solvents like alcohols and ketones, which can cause cracking or crazing. PVC tubing exhibits superior chemical resistance against a broader range of substances, particularly acids, bases, and oils, making it more suitable for aggressive chemical environments. Choosing between acrylic and PVC tubing depends heavily on the specific chemicals involved, with PVC generally providing better durability in harsh chemical applications.

Temperature Tolerance

Acrylic tubing withstands temperatures up to 160degF (71degC) before softening, making it suitable for moderate heat applications. PVC tubing has a lower temperature tolerance, generally softening around 140degF (60degC), which limits its use in high-temperature environments. Choosing between acrylic and PVC tubing depends on the required thermal resistance for specific industrial or laboratory settings.

Flexibility and Handling

Acrylic tubing offers rigid structure and superior clarity but lacks flexibility, making it less adaptable for applications requiring bending or contouring. PVC tubing provides excellent flexibility and impact resistance, allowing for easier handling and installation in complex or dynamic environments. Choosing between acrylic and PVC tubing depends on the specific need for rigidity versus flexibility in the intended use.

Common Applications of Each Tubing

Acrylic tubing is extensively used in applications requiring optical clarity, such as display cases, aquariums, and medical devices, owing to its high transparency and resistance to UV light. PVC tubing is commonly utilized in plumbing, chemical processing, and irrigation systems because of its chemical resistance, durability, and cost-effectiveness. Both materials serve specific industrial and commercial purposes, with acrylic favored for clarity and aesthetics, while PVC is preferred for robustness and versatility in fluid transport.

Cost Comparison: Acrylic vs PVC

Acrylic tubing generally costs more than PVC tubing due to its higher clarity, strength, and resistance to UV light and weathering, making it a premium choice for applications requiring visual appeal and durability. PVC tubing offers a significantly lower price point, making it a cost-effective solution for plumbing, irrigation, and industrial uses where clarity and aesthetics are less critical. The price difference can be up to 2-3 times, with acrylic tubes typically priced between $2 to $5 per foot compared to PVC tubing's $0.50 to $1.50 per foot, reflecting their distinct material properties and performance benefits.

Choosing the Right Tubing for Your Project

Acrylic tubing offers superior clarity and UV resistance compared to PVC tubing, making it ideal for projects requiring high visibility and outdoor durability. PVC tubing is more flexible and cost-effective, suited for applications where budget and easy installation are priorities. Selecting the right tubing depends on factors like environmental exposure, mechanical stress, and aesthetic needs to ensure optimal performance.

Acrylic Tubing vs PVC Tubing Infographic

materialdif.com

materialdif.com