Silica sand is composed primarily of quartz, making it highly durable and ideal for industrial applications like glass-making and foundry molds. River sand, characterized by its rounded grains and natural minerals, is commonly used in construction for concrete and plaster due to its smooth texture and easy workability. The choice between silica sand and river sand depends on factors such as purity, grain size, and the specific requirements of the project.

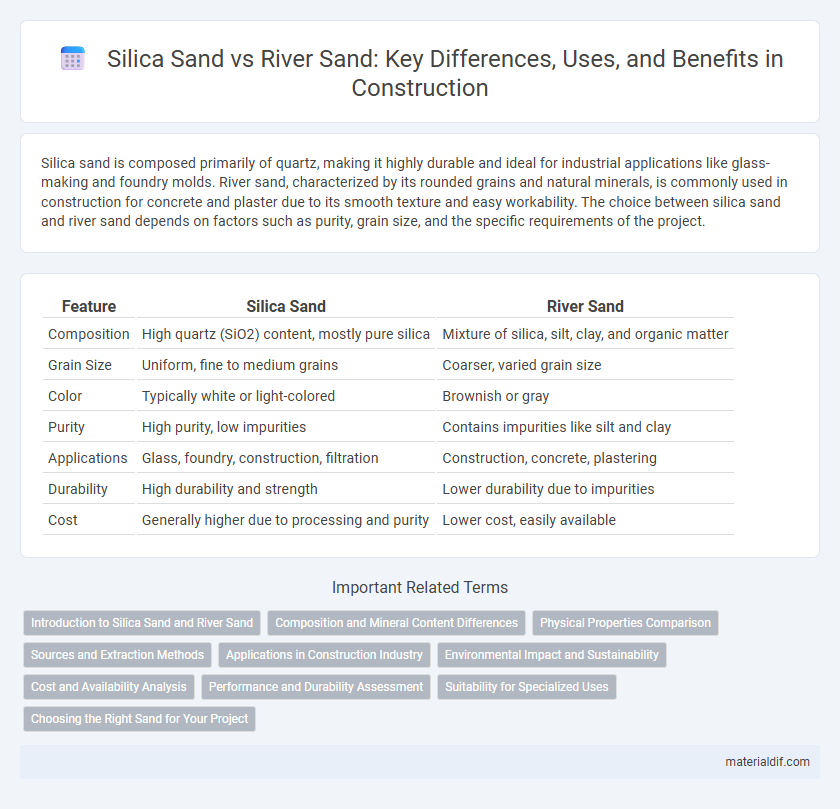

Table of Comparison

| Feature | Silica Sand | River Sand |

|---|---|---|

| Composition | High quartz (SiO2) content, mostly pure silica | Mixture of silica, silt, clay, and organic matter |

| Grain Size | Uniform, fine to medium grains | Coarser, varied grain size |

| Color | Typically white or light-colored | Brownish or gray |

| Purity | High purity, low impurities | Contains impurities like silt and clay |

| Applications | Glass, foundry, construction, filtration | Construction, concrete, plastering |

| Durability | High durability and strength | Lower durability due to impurities |

| Cost | Generally higher due to processing and purity | Lower cost, easily available |

Introduction to Silica Sand and River Sand

Silica sand, primarily composed of quartz, features high purity and uniform grain size essential for industrial applications such as glassmaking and foundry molds. River sand consists of naturally weathered particles, typically mixed minerals and organic matter, making it ideal for construction due to its angular shape and better binding properties. Differences in mineral composition and grain texture influence their suitability in various engineering and manufacturing processes.

Composition and Mineral Content Differences

Silica sand primarily consists of nearly pure quartz (SiO2), characterized by high silica content exceeding 95%, making it ideal for glassmaking and industrial applications. River sand contains a mixture of minerals such as quartz, feldspar, mica, and clay, with lower overall silica percentage and variable particle sizes due to erosion and sedimentation processes. The mineral content differences significantly impact the physical properties and suitability of each sand type for construction, foundry, and manufacturing purposes.

Physical Properties Comparison

Silica sand boasts a high quartz content, resulting in greater hardness and rounder grains compared to river sand, which contains a mix of mineral particles with more irregular shapes and softer textures. The uniform particle size and angularity of silica sand enhance its strength and durability in construction applications, while river sand's variable grain size can affect compaction and workability. Density differences also matter: silica sand typically exhibits a higher bulk density, influencing load-bearing capacity and structural stability in concrete mixes.

Sources and Extraction Methods

Silica sand is primarily sourced from quartz-rich sandstone deposits, extracted through mining techniques like open-pit mining and dredging, ensuring high purity and uniform grain size. River sand is naturally occurring, collected from riverbeds and banks through mechanical dredging or manual extraction, often containing a mix of minerals and organic materials. Extraction of silica sand involves beneficiation processes to remove impurities, while river sand typically requires minimal processing but may have variable quality due to sedimentation and environmental factors.

Applications in Construction Industry

Silica sand, known for its high purity and angular grains, is predominantly used in construction applications requiring strength and durability, such as concrete production, glass manufacturing, and hydraulic fracturing. River sand, characterized by its smooth, rounded particles, is commonly employed in plastering, bricklaying, and landscaping due to its workability and availability. The choice between silica sand and river sand significantly impacts the structural integrity and finishing quality of construction projects.

Environmental Impact and Sustainability

Silica sand mining often causes less environmental disruption compared to river sand extraction, which can lead to riverbank erosion, habitat destruction, and water pollution. The sustainability of silica sand depends on responsible quarrying practices and land reclamation efforts, whereas river sand extraction frequently exceeds natural replenishment rates, causing ecosystem imbalance. Choosing silica sand from regulated sources supports long-term environmental conservation and resource management.

Cost and Availability Analysis

Silica sand generally costs more than river sand due to its higher purity and specific industrial applications, making it a premium material in construction and manufacturing. River sand is more readily available and typically lower in price, especially in regions with abundant river beds, but its quality can vary significantly depending on the source. Cost-effectiveness and supply consistency depend on local extraction regulations, demand in construction projects, and transport logistics.

Performance and Durability Assessment

Silica sand, composed predominantly of quartz, offers superior hardness and chemical stability compared to river sand, resulting in enhanced performance in construction applications requiring durability and resistance to weathering. Its uniformly graded particles provide better compaction and bonding in concrete, reducing permeability and improving strength. River sand, often containing impurities and irregular grain sizes, tends to weaken structural integrity and reduce long-term durability.

Suitability for Specialized Uses

Silica sand offers high purity and consistent grain size, making it ideal for specialized uses such as glass manufacturing, foundry molds, and hydraulic fracturing. River sand contains varied particle sizes and organic impurities, which often limits its effectiveness in applications requiring uniformity and chemical stability. For projects demanding precision and specific material properties, silica sand is generally the preferred choice.

Choosing the Right Sand for Your Project

Silica sand, composed primarily of quartz, offers high purity and consistent grain size, making it ideal for industrial applications like glass manufacturing and construction requiring strength and durability. River sand, characterized by its natural, rounded grains and higher moisture content, suits general construction uses such as concrete and plaster, providing better workability and bonding. Selecting the right sand depends on project-specific requirements including strength, texture, and chemical composition to ensure optimal performance and longevity.

Silica Sand vs River Sand Infographic

materialdif.com

materialdif.com