River sand, naturally sourced from riverbeds, offers well-rounded grains ideal for construction and provides excellent strength and durability. Manufactured sand, produced by crushing rocks, delivers consistent particle size and shape, making it a sustainable alternative with better control over quality. Choosing between the two depends on project requirements, environmental impact, and availability.

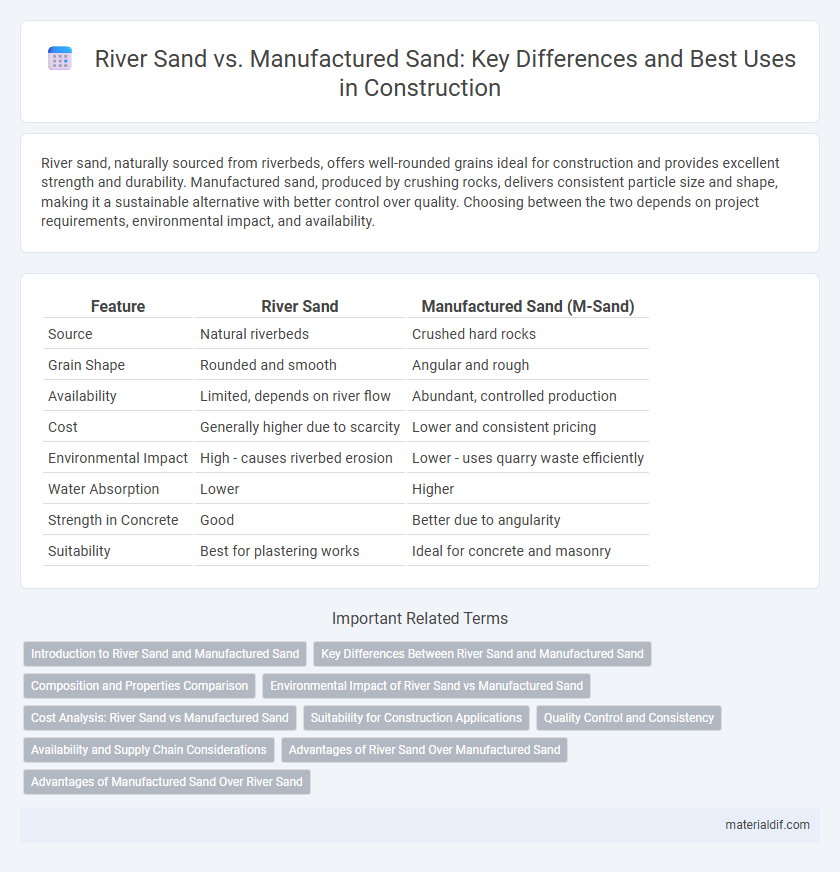

Table of Comparison

| Feature | River Sand | Manufactured Sand (M-Sand) |

|---|---|---|

| Source | Natural riverbeds | Crushed hard rocks |

| Grain Shape | Rounded and smooth | Angular and rough |

| Availability | Limited, depends on river flow | Abundant, controlled production |

| Cost | Generally higher due to scarcity | Lower and consistent pricing |

| Environmental Impact | High - causes riverbed erosion | Lower - uses quarry waste efficiently |

| Water Absorption | Lower | Higher |

| Strength in Concrete | Good | Better due to angularity |

| Suitability | Best for plastering works | Ideal for concrete and masonry |

Introduction to River Sand and Manufactured Sand

River sand, naturally sourced from riverbeds, is prized for its smooth texture and fine grain, making it ideal for construction and concrete production. Manufactured sand, produced by crushing hard granite or basalt rocks, offers a more angular shape and consistent particle size, providing enhanced strength and durability in building materials. Both types of sand play crucial roles in construction, with river sand favored for its workability and manufactured sand valued for sustainability and reduced environmental impact.

Key Differences Between River Sand and Manufactured Sand

River sand is naturally sourced from riverbeds, characterized by its smooth texture and rounded particles due to natural water erosion, making it ideal for construction projects requiring high workability. Manufactured sand (M-sand) is produced by crushing hard rocks, resulting in angular and rough particles that enhance the mechanical interlocking and strength of concrete. The main differences lie in their source, particle shape, and texture, where river sand offers natural smoothness and M-sand provides consistent quality and improved concrete strength for sustainable construction.

Composition and Properties Comparison

River sand consists mainly of natural quartz particles with smooth, rounded grains formed by water erosion, offering good workability and strength in construction. Manufactured sand is produced by crushing rocks, resulting in angular, rough-textured particles with higher fines content, which can improve bond strength but may affect water demand in concrete mixes. Compositionally, river sand is predominantly silica-based with few impurities, whereas manufactured sand may contain mineral fragments and require washing to reduce dust and clay content.

Environmental Impact of River Sand vs Manufactured Sand

River sand extraction leads to significant riverbank erosion, habitat destruction, and biodiversity loss, causing severe ecological imbalance in aquatic ecosystems. Manufactured sand production involves crushing rocks, which consumes less natural resources and reduces the depletion of riverbeds, lowering environmental degradation. The controlled process of manufacturing sand also minimizes sediment runoff and water pollution compared to unregulated river sand mining.

Cost Analysis: River Sand vs Manufactured Sand

River sand typically incurs higher costs due to extraction fees, transportation, and environmental regulations, making it more expensive than manufactured sand. Manufactured sand, produced by crushing rocks, offers a cost-effective alternative with consistent quality and lower transportation expenses, especially in urban areas. The long-term economic benefits of manufactured sand arise from reduced environmental impact fees and sustainable supply, impacting project budgeting significantly.

Suitability for Construction Applications

River sand offers natural fine aggregates with smooth texture and good particle shape, making it highly suitable for traditional concrete and plastering works. Manufactured sand, produced by crushing rocks, provides a more angular particle shape, enhancing the strength and workability of concrete in modern construction projects. Its consistent quality and availability make manufactured sand a preferred choice for large-scale infrastructure developments where controlled specifications are critical.

Quality Control and Consistency

River sand offers natural grain shapes and textures, but its quality can vary significantly due to seasonal changes and environmental factors, leading to inconsistent particle size and impurities. Manufactured sand, produced through crushing rocks under strict quality control measures, ensures consistent grading, particle shape, and cleanliness, making it more reliable for construction purposes. Rigorous testing protocols in manufactured sand production maintain uniformity, reducing variability in concrete strength compared to the unpredictable composition of river sand.

Availability and Supply Chain Considerations

River sand, sourced naturally from riverbeds, often faces depletion due to high demand and environmental regulations, leading to limited availability in many regions. Manufactured sand, produced by crushing rocks, offers a more consistent supply and can be tailored to meet specific construction standards, reducing reliance on natural riverbed extraction. The supply chain for manufactured sand is more controllable and less susceptible to seasonal disruptions compared to river sand, ensuring steady availability for large-scale projects.

Advantages of River Sand Over Manufactured Sand

River sand offers superior natural grain shape and smooth texture, resulting in better workability and finish in concrete applications. Its consistent particle size distribution enhances bonding strength and reduces the likelihood of voids, leading to higher durability. The natural filtration process of river sand also minimizes impurities, ensuring improved purity compared to manufactured sand.

Advantages of Manufactured Sand Over River Sand

Manufactured sand offers consistent particle size and shape, improving concrete workability and strength compared to the irregular grains of river sand. It reduces environmental degradation by minimizing riverbed excavation and supports sustainable construction practices. High availability and controlled quality make manufactured sand a reliable alternative amid dwindling natural river sand resources.

River sand vs Manufactured sand Infographic

materialdif.com

materialdif.com