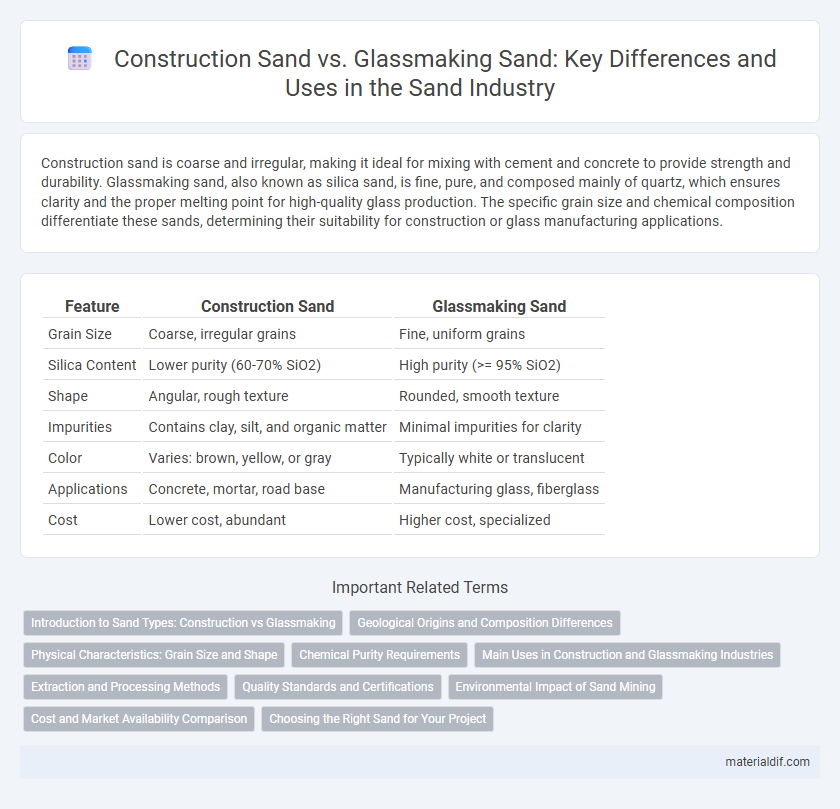

Construction sand is coarse and irregular, making it ideal for mixing with cement and concrete to provide strength and durability. Glassmaking sand, also known as silica sand, is fine, pure, and composed mainly of quartz, which ensures clarity and the proper melting point for high-quality glass production. The specific grain size and chemical composition differentiate these sands, determining their suitability for construction or glass manufacturing applications.

Table of Comparison

| Feature | Construction Sand | Glassmaking Sand |

|---|---|---|

| Grain Size | Coarse, irregular grains | Fine, uniform grains |

| Silica Content | Lower purity (60-70% SiO2) | High purity (>= 95% SiO2) |

| Shape | Angular, rough texture | Rounded, smooth texture |

| Impurities | Contains clay, silt, and organic matter | Minimal impurities for clarity |

| Color | Varies: brown, yellow, or gray | Typically white or translucent |

| Applications | Concrete, mortar, road base | Manufacturing glass, fiberglass |

| Cost | Lower cost, abundant | Higher cost, specialized |

Introduction to Sand Types: Construction vs Glassmaking

Construction sand is characterized by its coarse granules and high durability, making it ideal for concrete production, mortar, and road building. Glassmaking sand, also known as silica sand, features fine, uniform grains with high purity quartz content, essential for producing clear, strong glass. The mineral composition and grain size distribution distinctly influence the suitability of sand for construction or glass manufacturing applications.

Geological Origins and Composition Differences

Construction sand primarily originates from weathered rock deposits and riverbeds, consisting mainly of quartz and feldspar grains with varied sizes and shapes suited for concrete and mortar strength. Glassmaking sand is predominantly composed of highly pure, well-rounded silica (quartz) grains, often derived from specific sandstone formations or coastal dunes, ensuring minimal impurities for clear, high-quality glass production. The geological origins impact their composition, where construction sand's mixed mineral content enhances structural bonding, while glassmaking sand's purity and uniformity optimize melt clarity and consistency.

Physical Characteristics: Grain Size and Shape

Construction sand typically features coarser grains with irregular, angular shapes that enhance cement adhesion and structural stability. Glassmaking sand consists of finer, uniformly rounded grains, providing a smooth texture essential for high-quality glass clarity and strength. The distinct grain size and shape in each type optimize their performance for specific industrial applications.

Chemical Purity Requirements

Construction sand typically contains a mixture of minerals such as quartz, feldspar, and mica, with lower chemical purity standards due to its use in concrete and mortar where mechanical properties are prioritized. Glassmaking sand demands extremely high chemical purity, often over 95% silicon dioxide (SiO2), to ensure clarity and prevent impurities that can cause defects or color variations in the glass. The chemical purity requirements for glassmaking sand exclude contaminants like iron oxide, aluminum oxide, and organic matter, which are less critical in construction sand applications.

Main Uses in Construction and Glassmaking Industries

Construction sand, characterized by its coarse grains and high durability, is primarily used in concrete production, mortar mixtures, and as a base material for roads and foundations. Glassmaking sand, known as silica sand, contains high-purity quartz with fine, uniform grains ideal for melting into clear, strong glass products like windows, bottles, and fiberglass. The distinct grain size, purity, and composition determine the suitability of sand in the construction industry versus the glassmaking industry.

Extraction and Processing Methods

Construction sand is typically extracted from riverbeds, quarries, or pits through dredging and blasting, followed by screening and washing to remove impurities and achieve specific grain sizes suitable for concrete and mortar. Glassmaking sand requires higher purity silica content and is sourced mainly from specialized silica sand deposits, undergoing rigorous washing, magnetic separation, and acid leaching to eliminate iron and other contaminants that can affect glass clarity. The extraction and processing methods emphasize distinct purification and grading techniques to meet the performance standards of construction materials versus high-quality glass production.

Quality Standards and Certifications

Construction sand typically adheres to ASTM C33 and AASHTO M6 standards, ensuring proper particle size distribution, cleanliness, and strength for concrete and mortar applications. Glassmaking sand must meet stringent requirements such as low iron content and high silica purity, often certified under ISO 9001 and ASTM C778 for consistent optical clarity and durability. Both types require rigorous testing and certifications to guarantee performance quality tailored to their specific industrial uses.

Environmental Impact of Sand Mining

Construction sand mining often leads to significant environmental degradation, including habitat destruction, water table depletion, and increased erosion. Glassmaking sand, typically derived from high-purity silica sources, requires less extraction volume but still contributes to localized ecological disturbances. Sustainable sand mining practices and regulatory frameworks are crucial to minimize biodiversity loss and protect aquatic ecosystems associated with both types of sand extraction.

Cost and Market Availability Comparison

Construction sand typically has a lower cost due to its abundant availability and less stringent purity requirements, making it widely accessible in local markets. Glassmaking sand demands higher purity with minimal impurities like iron and clay, resulting in higher processing costs and limited availability primarily in specialized suppliers. Market availability for construction sand is extensive across regions, whereas glassmaking sand is rarer and often sourced from specific silica-rich deposits.

Choosing the Right Sand for Your Project

Construction sand, characterized by its coarse texture and durability, is ideal for concrete, mortar, and building foundations due to its strong binding properties. Glassmaking sand, composed of fine, high-purity silica with minimal impurities, is essential for producing clear, high-quality glass products. Selecting the appropriate sand based on particle size, purity, and application requirements ensures optimal performance and longevity in construction or glass manufacturing projects.

Construction sand vs Glassmaking sand Infographic

materialdif.com

materialdif.com