Desert sand and construction sand differ significantly in texture and composition, affecting their suitability for building projects. Desert sand is typically smoother and rounder due to wind erosion, which reduces its ability to bind effectively with cement. Construction sand, often sourced from rivers or quarries, has angular particles that provide better strength and stability in concrete and mortar mixes.

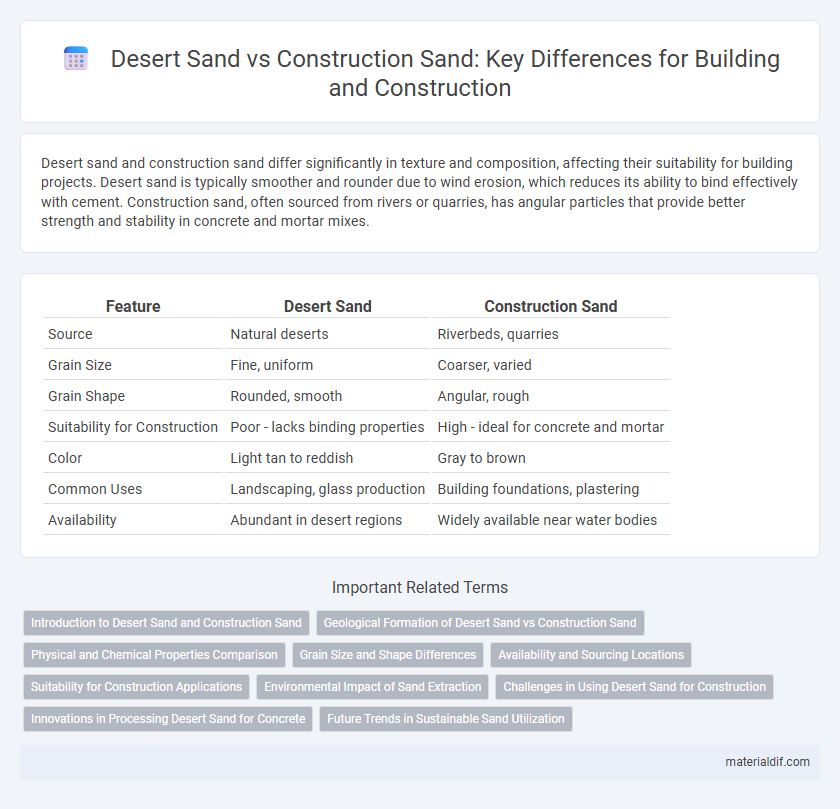

Table of Comparison

| Feature | Desert Sand | Construction Sand |

|---|---|---|

| Source | Natural deserts | Riverbeds, quarries |

| Grain Size | Fine, uniform | Coarser, varied |

| Grain Shape | Rounded, smooth | Angular, rough |

| Suitability for Construction | Poor - lacks binding properties | High - ideal for concrete and mortar |

| Color | Light tan to reddish | Gray to brown |

| Common Uses | Landscaping, glass production | Building foundations, plastering |

| Availability | Abundant in desert regions | Widely available near water bodies |

Introduction to Desert Sand and Construction Sand

Desert sand consists of fine, smooth grains shaped by wind erosion, making it less suitable for construction due to poor bonding with cement. Construction sand, often river or pit sand, features coarser, angular particles that provide better strength and stability in concrete mixtures. Understanding these differences is crucial for selecting the right sand type to ensure durable building structures.

Geological Formation of Desert Sand vs Construction Sand

Desert sand forms through prolonged weathering and erosion of rocks in arid environments, resulting in smooth, rounded grains with a high quartz content and uniform particle size due to wind abrasion. Construction sand, often river or pit sand, originates from the mechanical breakdown of rocks in fluvial or sedimentary processes, producing angular, coarse particles with diverse mineral compositions suited for concrete and mortar applications. The geological formation differences influence their texture and suitability, as desert sand's fine grains lack the binding properties required in construction materials.

Physical and Chemical Properties Comparison

Desert sand typically features fine, rounded grains with low angularity and is predominantly composed of quartz, exhibiting high silica content but minimal clay or organic impurities. Construction sand, also known as river or pit sand, contains coarser, more angular particles with diverse mineral content including mica, feldspar, and sometimes clay, resulting in better interlocking properties and higher load-bearing capacity. Chemically, construction sand may have higher concentrations of calcium carbonate and other minerals contributing to its binding qualities, contrasting with the chemically inert nature of desert sand that limits its suitability in concrete applications.

Grain Size and Shape Differences

Desert sand grains are typically fine and rounded due to prolonged wind erosion, resulting in smooth, spherical particles that hinder bonding in concrete mixtures. Construction sand, often river or pit sand, features coarser, angular grains with rough textures that improve the mechanical interlock and strength of building materials. Grain size distribution and shape significantly influence the suitability of sand types for various construction purposes.

Availability and Sourcing Locations

Desert sand, typically found in arid regions like the Sahara and Arabian deserts, is abundant but unsuitable for construction due to its smooth, rounded grains that do not bind well with cement. Construction sand, often sourced from riverbeds, quarries, and coastal areas such as white sand from rivers in the United States or quarry sand in Europe, has angular grains that provide better stability in concrete and mortar. Availability of construction sand is more consistent and regulated, meeting industry standards, whereas desert sand's availability is vast but its physical properties limit its usability in infrastructure projects.

Suitability for Construction Applications

Desert sand, characterized by its fine, rounded grains, lacks the angularity required for strong interlocking in concrete mixes, making it less suitable for construction applications. Construction sand, also known as manufactured or river sand, exhibits a coarser texture with rough, angular particles that enhance bonding with cement and improve structural strength. Using construction sand ensures better durability and stability in building foundations, concrete, and mortar compared to desert sand's tendency to reduce mix strength.

Environmental Impact of Sand Extraction

Desert sand extraction causes severe ecological disruption, leading to habitat destruction and increased desertification due to its fine, wind-blown particles that destabilize soil structure. Construction sand, typically mined from riverbeds or coastal areas, results in water pollution, erosion, and loss of aquatic biodiversity when over-extracted. Sustainable alternatives and regulated sand mining practices are crucial to minimize environmental degradation associated with both desert and construction sand extraction.

Challenges in Using Desert Sand for Construction

Desert sand poses significant challenges for construction due to its smooth, rounded grains that lack the angularity required for strong interlocking in concrete mixes. Unlike construction sand, which typically has rough, angular particles from riverbeds or quarries, desert sand's fine texture reduces the bond strength, leading to weaker concrete structures. Engineers must address issues such as increased water demand and reduced compressive strength when attempting to use desert sand in building materials.

Innovations in Processing Desert Sand for Concrete

Innovations in processing desert sand for concrete involve advanced techniques such as washing, grading, and coating to improve grain shape and reduce salt content, making it suitable for construction purposes. Researchers develop specialized additives and use chemical treatments to enhance the binding properties of desert sand, overcoming its natural smoothness and fine texture that typically hinder cement adhesion. These technological advancements enable sustainable concrete production by utilizing abundant desert resources, reducing reliance on limited conventional construction sand sources.

Future Trends in Sustainable Sand Utilization

Desert sand, characterized by its fine, rounded grains, is less suitable for construction due to poor binding properties, prompting a shift toward sustainable alternatives in building materials. Innovations include recycling industrial byproducts and mining river or manufactured sand to reduce environmental impacts from traditional quarrying. Future trends emphasize eco-friendly sourcing, improving material performance, and integrating circular economy principles to meet rising construction demands while preserving natural landscapes.

Desert Sand vs Construction Sand Infographic

materialdif.com

materialdif.com