Silica sand, composed primarily of quartz, is known for its high hardness and chemical inertness, making it ideal for glassmaking and industrial filtration. Garnet sand, with its greater density and sharp edges, excels in abrasive blasting and waterjet cutting due to its superior hardness and durability. Choosing between silica and garnet sand depends on the specific application requirements, including hardness, particle shape, and chemical stability.

Table of Comparison

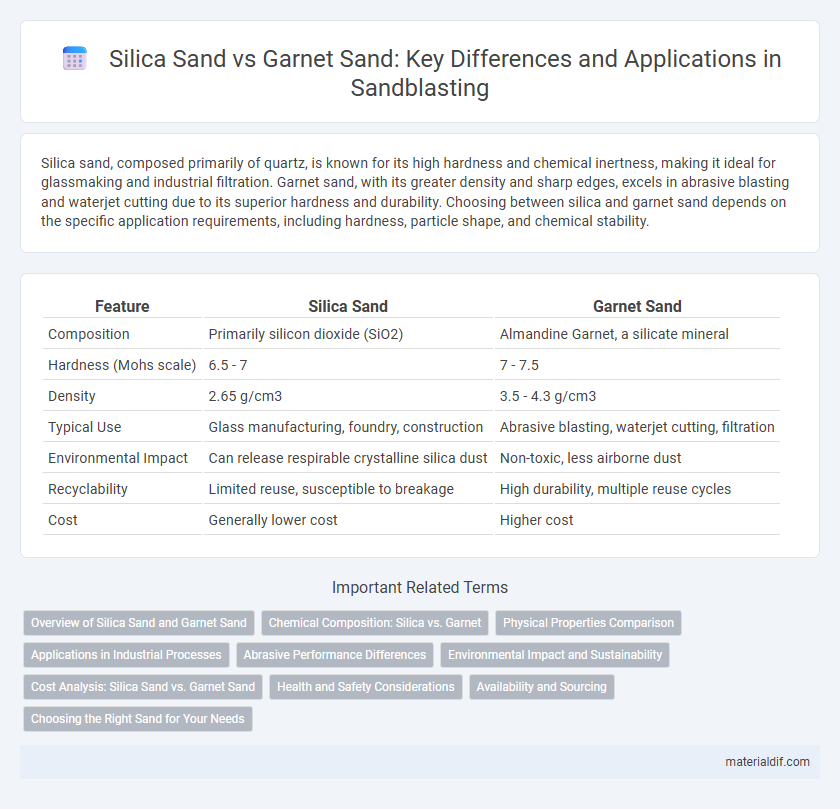

| Feature | Silica Sand | Garnet Sand |

|---|---|---|

| Composition | Primarily silicon dioxide (SiO2) | Almandine Garnet, a silicate mineral |

| Hardness (Mohs scale) | 6.5 - 7 | 7 - 7.5 |

| Density | 2.65 g/cm3 | 3.5 - 4.3 g/cm3 |

| Typical Use | Glass manufacturing, foundry, construction | Abrasive blasting, waterjet cutting, filtration |

| Environmental Impact | Can release respirable crystalline silica dust | Non-toxic, less airborne dust |

| Recyclability | Limited reuse, susceptible to breakage | High durability, multiple reuse cycles |

| Cost | Generally lower cost | Higher cost |

Overview of Silica Sand and Garnet Sand

Silica sand primarily consists of quartz and is valued for its high silica content, making it ideal for applications like glass manufacturing, foundry molds, and filtration systems due to its hardness and chemical inertness. Garnet sand is composed of metamorphic minerals that are denser and more angular than silica sand, offering superior abrasion resistance and is commonly used in waterjet cutting, abrasive blasting, and high-pressure water filtration. Both sands differ significantly in mineral composition, hardness, and industrial use, with silica sand favored for purity and garnet sand preferred for abrasive and filtration efficiency.

Chemical Composition: Silica vs. Garnet

Silica sand primarily consists of silicon dioxide (SiO2), offering high hardness and chemical stability essential for industrial applications like glassmaking and foundry casting. Garnet sand contains a complex mix of minerals including almandine, pyrope, and spessartine, rich in iron and aluminum silicates, providing greater density and abrasion resistance. The distinct chemical compositions influence their suitability for different abrasive blasting and filtration processes.

Physical Properties Comparison

Silica sand features a high hardness of 7 on the Mohs scale, offering excellent abrasion resistance and a density of approximately 2.65 g/cm3, making it ideal for industrial applications requiring durability. Garnet sand, with a hardness ranging from 6.5 to 7.5 and a higher density around 4.2 to 4.3 g/cm3, provides superior cutting and polishing capabilities due to its greater specific gravity and angular grain shape. The angularity and density differences between silica and garnet sands significantly impact their performance in abrasive blasting and filtration processes.

Applications in Industrial Processes

Silica sand is widely used in glass manufacturing, foundry casting, and hydraulic fracturing due to its high quartz content and resistance to heat and chemical reactions. Garnet sand is favored in abrasive blasting, waterjet cutting, and filtration systems because of its hardness, angular shape, and chemical stability. Industrial processes leverage silica sand for its silica purity in molds and filtration media, while garnet sand's superior abrasive qualities enhance surface preparation and precision cutting applications.

Abrasive Performance Differences

Silica sand exhibits high hardness and angularity, making it effective for aggressive abrasive blasting but with increased dust generation and health concerns due to respirable crystalline silica. Garnet sand offers superior abrasion resistance and a sharper particle shape, resulting in faster cutting rates, less dust, and recyclability that reduces operational costs. The choice between silica and garnet sands depends on the balance between abrasive efficiency, environmental impact, and application-specific requirements.

Environmental Impact and Sustainability

Silica sand extraction often results in significant environmental degradation, including habitat disruption and silica dust pollution, which poses health risks to workers and nearby communities. Garnet sand mining generally has a lower environmental impact due to its fewer hazardous dust emissions and more sustainable extraction methods, promoting ecosystem preservation. Sustainable practices in garnet mining include recycling and minimizing water usage, making it a greener choice compared to conventional silica sand operations.

Cost Analysis: Silica Sand vs. Garnet Sand

Silica sand typically costs less than garnet sand, with prices averaging around $30 to $50 per ton compared to garnet's $80 to $120 per ton, making silica sand more cost-effective for large-scale projects. The higher hardness and durability of garnet sand justify its premium price in abrasive blasting and waterjet cutting applications where precision and minimal wear are critical. Cost analysis must weigh initial material expense against longevity and performance efficiency in specific industrial uses.

Health and Safety Considerations

Silica sand poses significant health risks due to its fine crystalline silica particles, which can cause silicosis and other respiratory diseases when inhaled over prolonged periods. Garnet sand, being chemically inert and coarser, presents fewer airborne hazards and is generally safer for workers in industrial applications. Proper personal protective equipment and dust control measures are essential to mitigate exposure risks associated with both materials.

Availability and Sourcing

Silica sand boasts widespread availability due to extensive natural deposits found globally, especially in regions like the United States, Australia, and Europe, making it easier to source at lower costs. Garnet sand, while less abundant, is primarily sourced from specific regions such as India, Australia, and the United States, resulting in more limited but high-quality supplies for specialized industrial applications. The sourcing of garnet sand often involves stricter environmental regulations and higher mining costs compared to silica sand, influencing its market availability and price stability.

Choosing the Right Sand for Your Needs

Silica sand, primarily composed of quartz, offers high hardness and chemical inertness, making it ideal for glassmaking, filtration, and industrial applications requiring durability. Garnet sand, known for its higher specific gravity and angular shape, provides superior abrasion resistance and faster cut rates, favored in abrasive blasting and waterjet cutting. Selecting the right sand depends on factors like application purpose, desired abrasiveness, and particle size distribution to optimize performance and cost-efficiency.

Silica sand vs Garnet sand Infographic

materialdif.com

materialdif.com