Screened sand undergoes a thorough process to remove impurities, resulting in a uniform grain size ideal for construction, concrete mixing, and landscaping projects. In contrast, unscreened sand contains varying particle sizes, dirt, and debris, which can compromise structural integrity and lead to uneven surfaces. Choosing screened sand ensures better consistency, enhanced workability, and improved durability in building applications.

Table of Comparison

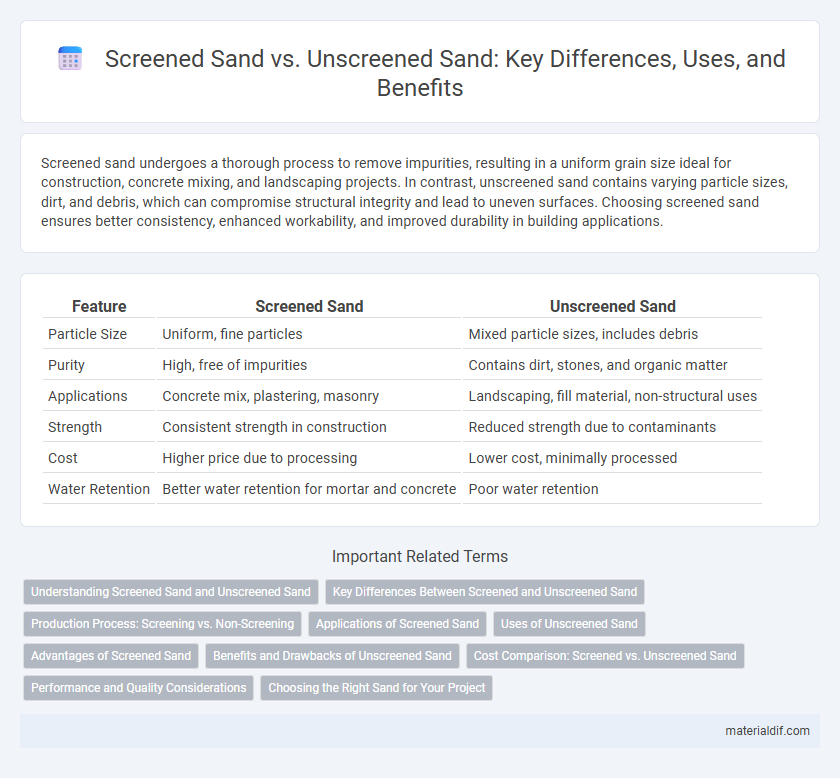

| Feature | Screened Sand | Unscreened Sand |

|---|---|---|

| Particle Size | Uniform, fine particles | Mixed particle sizes, includes debris |

| Purity | High, free of impurities | Contains dirt, stones, and organic matter |

| Applications | Concrete mix, plastering, masonry | Landscaping, fill material, non-structural uses |

| Strength | Consistent strength in construction | Reduced strength due to contaminants |

| Cost | Higher price due to processing | Lower cost, minimally processed |

| Water Retention | Better water retention for mortar and concrete | Poor water retention |

Understanding Screened Sand and Unscreened Sand

Screened sand is processed through fine mesh screens to remove larger particles, debris, and impurities, resulting in uniform grain size ideal for construction and industrial use. Unscreened sand contains a mix of various sizes, including coarse particles and organic matter, which can affect strength, texture, and overall quality in applications. Understanding the differences ensures appropriate selection for projects requiring specific sand texture and cleanliness, such as concrete mixing or landscaping.

Key Differences Between Screened and Unscreened Sand

Screened sand undergoes a process where it passes through mesh screens to remove impurities and larger particles, resulting in uniform particle size ideal for construction and concrete mixing. Unscreened sand contains varied particle sizes and debris, making it less consistent and suitable primarily for landscaping or fill applications. The main differences include particle uniformity, cleanliness, and adaptability to specific building standards or projects.

Production Process: Screening vs. Non-Screening

Screened sand undergoes a rigorous production process involving mechanical screening to remove impurities and unwanted particles, resulting in uniform grain size ideal for construction and industrial applications. Unscreened sand bypasses this step, retaining natural mixtures of coarse and fine particles, which may affect consistency and quality in finished products. Screening enhances material purity and improves performance characteristics, making screened sand a preferred choice for precision-required projects.

Applications of Screened Sand

Screened sand is extensively used in construction and industrial applications due to its uniform particle size and cleanliness, which enhance the strength and durability of concrete and mortar mixes. It is ideal for plastering, brick laying, and making high-quality concrete where impurities and oversized particles could compromise structural integrity. The controlled grading of screened sand also improves workability and reduces the risk of segregation in finished products.

Uses of Unscreened Sand

Unscreened sand is commonly used in construction projects where filtration is not critical, such as backfilling trenches, bedding pipes, and filling voids. It is ideal for landscaping and agricultural applications where natural soil composition and drainage patterns are required. The coarse particles and presence of debris make unscreened sand cost-effective for projects that do not need fine, uniform sand texture.

Advantages of Screened Sand

Screened sand offers superior consistency and uniform particle size, making it ideal for construction and landscaping applications that require precise material quality. Its removal of larger debris and impurities enhances workability, ensuring smoother surfaces and stronger structural integrity. The controlled gradation of screened sand improves compaction and drainage properties, leading to more durable and reliable end results.

Benefits and Drawbacks of Unscreened Sand

Unscreened sand contains a mixture of fine particles, organic matter, and debris, which can reduce its quality for construction purposes by affecting consistency and compaction. The benefits of unscreened sand include lower cost and less processing time, making it suitable for non-structural or landscaping applications. Drawbacks involve potential contamination, reduced strength in concrete mixes, and increased risk of clogging in drainage systems, limiting its use in precise engineering contexts.

Cost Comparison: Screened vs. Unscreened Sand

Screened sand generally incurs higher costs due to the additional processing required to remove impurities and particles, resulting in a more refined and consistent product. Unscreened sand is typically less expensive but may contain debris, affecting its suitability for precise construction tasks. Cost differences vary by region and supplier, with screened sand favored for applications demanding quality despite the premium price.

Performance and Quality Considerations

Screened sand exhibits superior performance and quality through uniform particle size distribution, enhancing compaction and reducing voids in construction applications. Unscreened sand contains variable-sized particles and impurities, which may compromise strength consistency and increase water demand in concrete mixes. Selecting screened sand is crucial for achieving optimal structural integrity and durability in building projects.

Choosing the Right Sand for Your Project

Screened sand offers uniform particle size and cleanliness, making it ideal for precise construction and masonry projects requiring consistent texture and strength. Unscreened sand contains varying particle sizes and impurities, suitable for landscaping or fill material where exact specifications are less critical. Choosing the right sand depends on project requirements for durability, finish, and structural integrity.

Screened sand vs Unscreened sand Infographic

materialdif.com

materialdif.com