Heavy mineral sand contains dense minerals such as ilmenite, rutile, and zircon, which are valuable for industrial applications like titanium production and ceramics. Light mineral sand primarily consists of quartz and feldspar, commonly used in glassmaking and construction due to its lower density and abundance. Understanding the differences in composition and density helps determine the most suitable use for each type of sand in various industries.

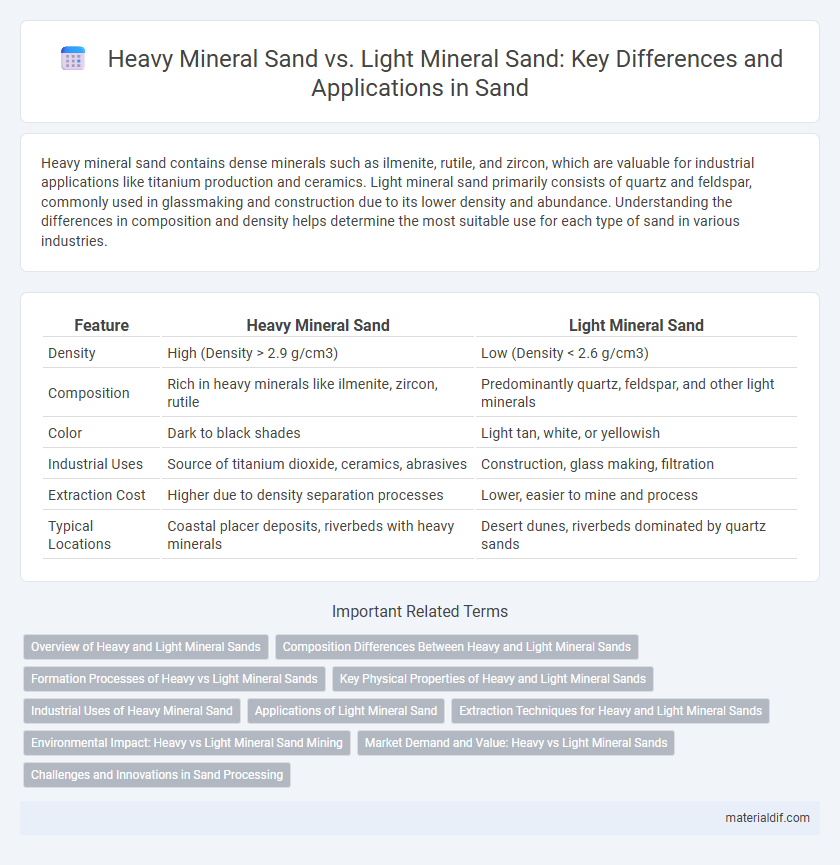

Table of Comparison

| Feature | Heavy Mineral Sand | Light Mineral Sand |

|---|---|---|

| Density | High (Density > 2.9 g/cm3) | Low (Density < 2.6 g/cm3) |

| Composition | Rich in heavy minerals like ilmenite, zircon, rutile | Predominantly quartz, feldspar, and other light minerals |

| Color | Dark to black shades | Light tan, white, or yellowish |

| Industrial Uses | Source of titanium dioxide, ceramics, abrasives | Construction, glass making, filtration |

| Extraction Cost | Higher due to density separation processes | Lower, easier to mine and process |

| Typical Locations | Coastal placer deposits, riverbeds with heavy minerals | Desert dunes, riverbeds dominated by quartz sands |

Overview of Heavy and Light Mineral Sands

Heavy mineral sands contain dense minerals like ilmenite, zircon, and rutile, which are valuable for titanium extraction and industrial applications. Light mineral sands primarily consist of quartz and feldspar, used extensively in glassmaking, ceramics, and construction. The density difference between heavy and light mineral sands influences their separation processes and end-use industries.

Composition Differences Between Heavy and Light Mineral Sands

Heavy mineral sands are rich in dense minerals such as ilmenite, rutile, zircon, and magnetite, which have specific gravities typically above 2.85, making them valuable for industrial applications like pigment production and metal extraction. Light mineral sands primarily consist of quartz and feldspar with specific gravities below 2.65, reflecting their lower density and different economic uses, usually in construction and glassmaking. The contrasting mineral compositions directly influence the sand's physical properties, processing methods, and end-use applications.

Formation Processes of Heavy vs Light Mineral Sands

Heavy mineral sands form through the weathering and erosion of pre-existing rocks rich in dense minerals like ilmenite, zircon, and rutile, with subsequent transport and deposition by water or wind concentrating these heavy minerals due to their higher specific gravity. Light mineral sands primarily consist of quartz and feldspar, created from the breakdown of continental rocks, and are deposited in environments where lighter particles settle more readily, such as beaches and riverbeds. The contrasting formation processes hinge on mineral density and hydrodynamic sorting, leading to the spatial separation of heavy and light mineral-rich deposits.

Key Physical Properties of Heavy and Light Mineral Sands

Heavy mineral sands exhibit higher specific gravity, typically above 2.9, compared to light mineral sands which usually have specific gravity below 2.7. The particle density of heavy mineral sands ranges from 2.9 to 4.5 g/cm3, reflecting minerals like ilmenite, zircon, and rutile, while light mineral sands consist mainly of quartz and feldspar with densities around 2.6 to 2.7 g/cm3. Additionally, heavy mineral sands have greater magnetic susceptibility and higher resistance to abrasion, affecting their industrial applications in heavy mineral extraction and processing.

Industrial Uses of Heavy Mineral Sand

Heavy mineral sand is rich in valuable minerals like ilmenite, zircon, and rutile, which are crucial for industrial applications including the production of titanium dioxide pigments, ceramics, and refractory materials. Its high density and unique composition make it suitable for use in aerospace, electronics, and paint manufacturing industries. Unlike light mineral sand, which is predominantly quartz and used mainly in construction, heavy mineral sand's industrial value lies in its diverse and high-demand mineral content.

Applications of Light Mineral Sand

Light mineral sand, primarily composed of quartz and feldspar, is extensively used in glass manufacturing due to its high silica content and purity. Its low density and high whiteness make it ideal for producing ceramics, paints, and fillers in the plastics industry. Additionally, light mineral sand serves as a crucial raw material in construction for concrete and mortar, enhancing strength and durability.

Extraction Techniques for Heavy and Light Mineral Sands

Extraction techniques for heavy mineral sands typically involve dredging, hydraulic mining, and dry mining methods that target dense minerals like ilmenite, rutile, and zircon, which settle in concentrated layers due to their higher specific gravity. Light mineral sands, often rich in quartz and feldspar, are extracted through open-pit mining and conventional earth-moving equipment, focusing on volume rather than density separation. Advanced separation technologies such as gravity separation, magnetic separation, and flotation are crucial for isolating heavy minerals from the sand matrix efficiently.

Environmental Impact: Heavy vs Light Mineral Sand Mining

Heavy mineral sand mining often results in greater environmental disruption due to the extraction of dense minerals like ilmenite, rutile, and zircon, which typically require more intensive processing and generate substantial waste. Light mineral sand mining, targeting minerals such as quartz and feldspar, generally causes less habitat destruction and lower levels of soil erosion but still poses risks of water contamination and dust pollution. Both mining types impact coastal ecosystems, but the heavier minerals' extraction frequently leads to longer recovery periods and more significant ecological disturbance.

Market Demand and Value: Heavy vs Light Mineral Sands

Heavy mineral sands, rich in titanium, zircon, and rare earth elements, command higher market demand due to their critical applications in aerospace, electronics, and pigments. Light mineral sands, primarily composed of quartz and feldspar, have lower value and demand, mostly used in construction and glass manufacturing. The global market value of heavy mineral sands significantly exceeds that of light sands, driven by scarcity and technological importance.

Challenges and Innovations in Sand Processing

Heavy mineral sands, containing valuable minerals like ilmenite, zircon, and rutile, present processing challenges due to their density and mineral complexity, requiring advanced separation technologies such as spiral concentrators and magnetic separators. Light mineral sands, dominated by quartz and feldspar, demand innovative methods to enhance purity and reduce fines, often utilizing flotation and screening innovations. Emerging innovations in sensor-based sorting and eco-friendly beneficiation are improving recovery rates and reducing environmental impact in both heavy and light mineral sand processing.

Heavy mineral sand vs Light mineral sand Infographic

materialdif.com

materialdif.com