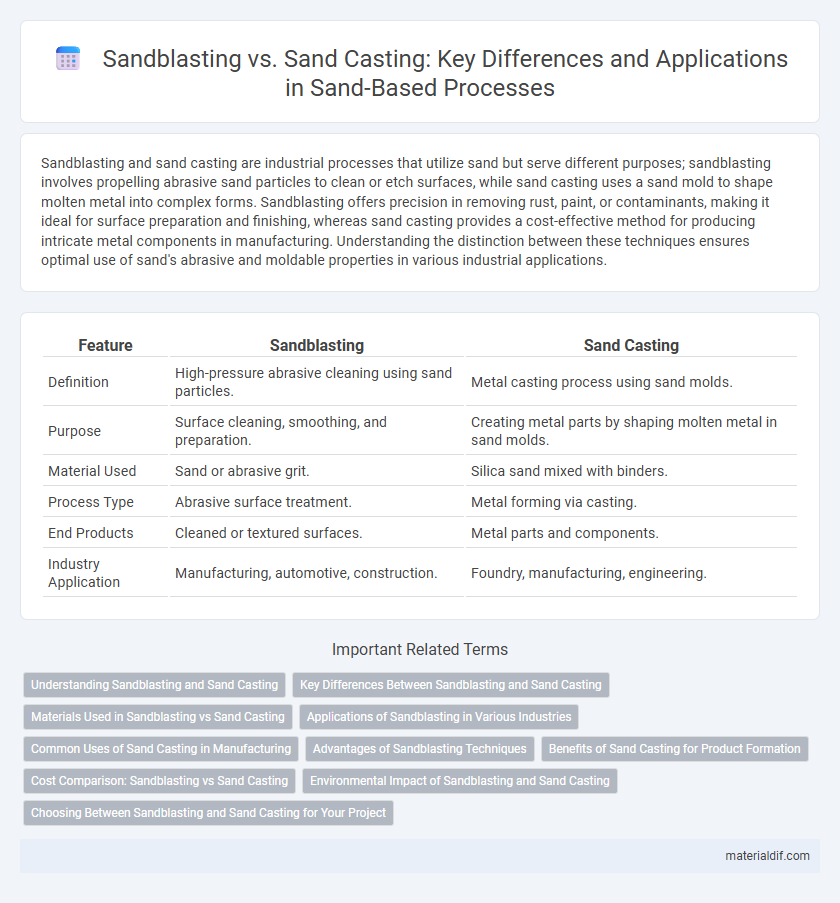

Sandblasting and sand casting are industrial processes that utilize sand but serve different purposes; sandblasting involves propelling abrasive sand particles to clean or etch surfaces, while sand casting uses a sand mold to shape molten metal into complex forms. Sandblasting offers precision in removing rust, paint, or contaminants, making it ideal for surface preparation and finishing, whereas sand casting provides a cost-effective method for producing intricate metal components in manufacturing. Understanding the distinction between these techniques ensures optimal use of sand's abrasive and moldable properties in various industrial applications.

Table of Comparison

| Feature | Sandblasting | Sand Casting |

|---|---|---|

| Definition | High-pressure abrasive cleaning using sand particles. | Metal casting process using sand molds. |

| Purpose | Surface cleaning, smoothing, and preparation. | Creating metal parts by shaping molten metal in sand molds. |

| Material Used | Sand or abrasive grit. | Silica sand mixed with binders. |

| Process Type | Abrasive surface treatment. | Metal forming via casting. |

| End Products | Cleaned or textured surfaces. | Metal parts and components. |

| Industry Application | Manufacturing, automotive, construction. | Foundry, manufacturing, engineering. |

Understanding Sandblasting and Sand Casting

Sandblasting uses high-pressure air or water mixed with abrasive sand particles to clean, smooth, or etch surfaces, making it essential for surface preparation in manufacturing and restoration. Sand casting involves creating a mold from sand to shape molten metal into complex parts, valued for its cost-effectiveness and versatility in producing large, intricate metal components. Both processes utilize sand but serve distinct purposes: surface treatment in sandblasting versus metal shaping in sand casting.

Key Differences Between Sandblasting and Sand Casting

Sandblasting is a surface finishing technique that uses high-pressure abrasive materials to clean or texture surfaces, while sand casting is a metal casting process that creates complex metal parts by pouring molten metal into a sand mold. The primary difference lies in their purpose: sandblasting is used for surface preparation or restoration, whereas sand casting is used for manufacturing metal components. Sandblasting requires equipment like compressors and abrasive media, whereas sand casting involves creating molds and handling molten metals under controlled conditions.

Materials Used in Sandblasting vs Sand Casting

Sandblasting primarily uses abrasive materials such as silica sand, garnet, or aluminum oxide to clean, etch, or smooth surfaces. Sand casting relies on a special type of sand mixed with binders like clay or chemical resins to create molds that withstand the high temperatures of molten metal. The material composition directly affects the efficiency and quality of both processes, with sandblasting abrasives focused on surface texture and sand casting sand designed for mold durability.

Applications of Sandblasting in Various Industries

Sandblasting is widely applied in automotive manufacturing for surface preparation and rust removal, enhancing paint adhesion and durability. In construction, it effectively cleans and profiles concrete surfaces, improving bonding for coatings and sealants. Additionally, the aerospace industry uses sandblasting to maintain and restore aircraft components by removing corrosion and contaminants without damaging sensitive materials.

Common Uses of Sand Casting in Manufacturing

Sand casting is widely used in manufacturing to produce complex metal parts with intricate geometries, such as engine blocks, pipes, and machinery components. Its ability to accommodate large sizes and a variety of metals, including iron, aluminum, and bronze, makes it ideal for heavy-duty applications in automotive, aerospace, and industrial sectors. The cost-effectiveness and versatility of sand casting enable efficient production of prototype and large-scale runs.

Advantages of Sandblasting Techniques

Sandblasting offers precise surface cleaning and preparation by using high-pressure abrasive materials, enhancing adhesion for coatings and paints. Its ability to remove rust, scale, and contaminants from complex shapes improves the durability and quality of metal parts. Compared to sand casting, sandblasting ensures smoother finishes and reduces the risk of defects in final products.

Benefits of Sand Casting for Product Formation

Sand casting offers exceptional design flexibility, allowing complex geometries and large components to be produced with relative ease and cost-efficiency. It provides superior surface finish and dimensional accuracy compared to sandblasting, which is primarily a surface treatment process. The ability to use a wide range of metals and alloys in sand casting enhances material versatility, making it ideal for producing durable and high-strength products.

Cost Comparison: Sandblasting vs Sand Casting

Sandblasting typically involves lower initial equipment costs but incurs higher ongoing expenses due to abrasive material consumption and maintenance. In contrast, sand casting requires significant upfront investment in mold design and pattern making but offers cost efficiency for large production runs. Overall, sand casting becomes more economical at higher volumes, whereas sandblasting remains cost-effective for smaller, precision cleaning or finishing tasks.

Environmental Impact of Sandblasting and Sand Casting

Sandblasting generates significant dust and airborne particulate matter that can harm air quality and pose health risks to workers without proper containment and filtration systems. Sand casting produces waste sand that often contains binders and requires appropriate disposal or recycling to prevent soil and water contamination. Both processes necessitate environmental management practices to mitigate their impact on ecosystems and comply with regulatory standards.

Choosing Between Sandblasting and Sand Casting for Your Project

Choosing between sandblasting and sand casting depends on the project requirements, as sandblasting is a surface treatment process that cleans or textures metal surfaces using high-pressure sand particles. Sand casting involves creating a mold from sand to shape molten metal into complex components, ideal for manufacturing parts with intricate geometries. For projects emphasizing surface finishing or cleaning, sandblasting is preferable, whereas sand casting suits fabrication of durable metal parts with detailed forms.

Sandblasting vs Sand casting Infographic

materialdif.com

materialdif.com