Glass sand, characterized by its high silica content and fine grains, is specifically used for producing clear, high-quality glass, whereas building sand, with coarser particles and varied composition, is ideal for construction applications like mortar and concrete. The purity and particle size of glass sand ensure minimal impurities, which is crucial for the transparency and strength of glass products. In contrast, building sand's versatility and structural properties make it suitable for creating durable and stable building materials.

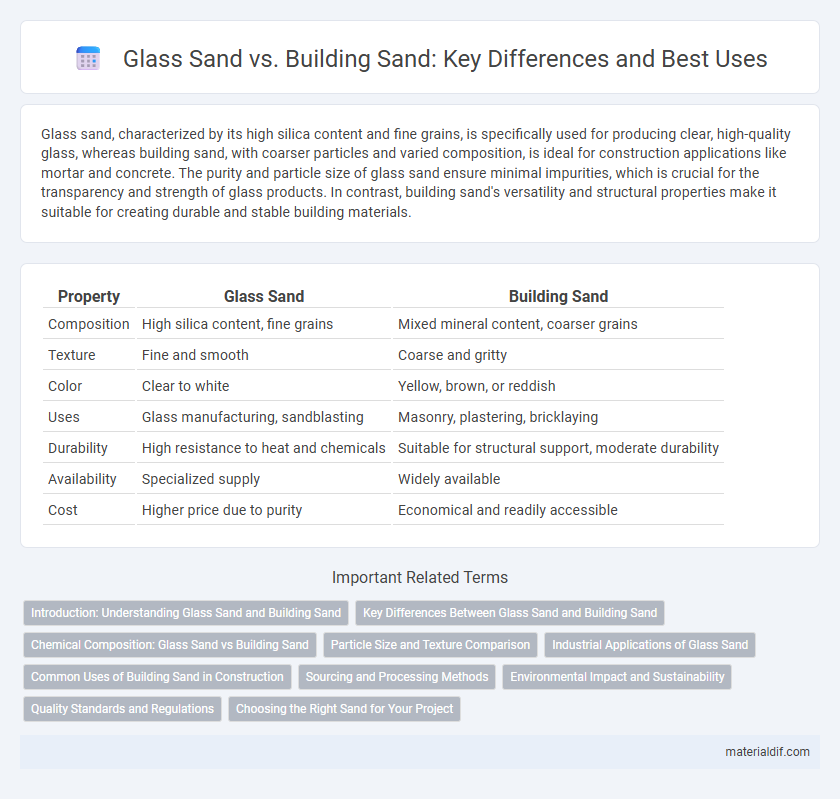

Table of Comparison

| Property | Glass Sand | Building Sand |

|---|---|---|

| Composition | High silica content, fine grains | Mixed mineral content, coarser grains |

| Texture | Fine and smooth | Coarse and gritty |

| Color | Clear to white | Yellow, brown, or reddish |

| Uses | Glass manufacturing, sandblasting | Masonry, plastering, bricklaying |

| Durability | High resistance to heat and chemicals | Suitable for structural support, moderate durability |

| Availability | Specialized supply | Widely available |

| Cost | Higher price due to purity | Economical and readily accessible |

Introduction: Understanding Glass Sand and Building Sand

Glass sand, primarily composed of high-purity silica quartz, is characterized by its fine grain size and low levels of impurities, making it ideal for manufacturing clear, high-quality glass. Building sand, often known as sharp sand or concrete sand, contains coarser grains with a mix of quartz and other minerals, providing the necessary texture and strength required for construction applications such as mortar and concrete. The distinct mineral composition and grain size distribution differentiate glass sand from building sand, defining their specialized uses in industry and construction.

Key Differences Between Glass Sand and Building Sand

Glass sand, primarily composed of fine, rounded silica particles, offers high purity and uniform grain size ideal for glass manufacturing; building sand contains coarser, angular grains with impurities like clay and silt, providing better compaction and strength for construction purposes. The chemical composition and grain texture in glass sand result in superior melting characteristics and clarity, whereas building sand's varied texture enhances mortar adhesion and load-bearing capacity. These distinct properties define their specialized applications: glass sand for producing clear, durable glass products, and building sand for masonry, concrete, and plastering work.

Chemical Composition: Glass Sand vs Building Sand

Glass sand primarily consists of high-purity silica (SiO2) with minimal impurities such as iron oxide and alumina, ensuring optimal clarity and strength for glass manufacturing. Building sand contains a broader mixture of minerals including silica, feldspar, and clay, resulting in varied chemical compositions that provide better binding properties for construction purposes. The purity and uniformity of chemical components in glass sand significantly contrast with the heterogeneous and impurity-rich nature of building sand.

Particle Size and Texture Comparison

Glass sand typically features finer and more uniform particle sizes ranging from 0.1 to 0.5 millimeters, offering smooth texture ideal for melting and forming clear glass. Building sand contains coarser particles, often between 0.5 and 2 millimeters, with a rougher texture that enhances binding strength in mortar and concrete. The particle size distribution and texture differences directly influence their suitability for either glass manufacturing or construction applications.

Industrial Applications of Glass Sand

Glass sand, primarily composed of high-purity silica, is essential in industrial applications such as glass manufacturing, where its fine grain size and chemical purity ensure the production of clear, durable glass products. Unlike building sand, which contains more impurities and coarser particles suited for construction purposes like concrete and mortar, glass sand provides the necessary consistency for melting and forming processes in industries producing flat glass, fiberglass, and specialty glassware. Its specific properties enable optimal thermal resistance and transparency, making it indispensable in sectors requiring high-quality glass materials.

Common Uses of Building Sand in Construction

Building sand, characterized by its fine texture and uniform grain size, is primarily used for mortar mixes, plastering, and bricklaying in construction projects. It provides excellent workability and strength when combined with cement and water, making it ideal for creating durable walls, floors, and pavements. Unlike glass sand, building sand's composition supports structural stability and smooth finishes, essential features in residential and commercial building applications.

Sourcing and Processing Methods

Glass sand, predominantly composed of high-purity silica (SiO2), is sourced from specific quartz-rich deposits with minimal impurities to ensure clarity and strength in glass production. It undergoes thorough washing and screening to remove contaminants like clay, silt, and iron oxides, followed by drying and sometimes beneficiation to achieve the required particle size and chemical purity. Building sand, sourced from riverbanks or pits, often contains a mixture of silica, feldspar, and clay; it requires minimal processing, typically just drying and grading, tailored to construction needs rather than chemical purity.

Environmental Impact and Sustainability

Glass sand typically has a lower environmental impact than building sand because it is often sourced from recycled glass, reducing the need for virgin material extraction and minimizing landfill waste. Building sand extraction can lead to habitat disruption, soil erosion, and groundwater depletion, raising sustainability concerns in construction projects. Utilizing glass sand supports circular economy principles by promoting recycling and conserving natural sand resources.

Quality Standards and Regulations

Glass sand, primarily composed of high-purity silica, adheres to stringent quality standards such as ASTM C144 and EN 12620 to ensure low impurity levels for optimal glass clarity and strength. Building sand, including sharp sand and soft sand, follows different regulations like BS EN 13139, emphasizing grain size distribution and cleanliness for structural integrity and workability in construction. Compliance with these specific standards ensures that glass sand meets the exacting requirements for glass manufacturing, while building sand is suitable for various construction purposes, maintaining safety and durability.

Choosing the Right Sand for Your Project

Glass sand, characterized by its high silica content and fine grain size, is ideal for producing clear, durable glass products, while building sand features coarser grains and impurities suited for construction and mortar work. Selecting the right sand depends on project requirements: glass sand ensures clarity and strength in glassmaking, whereas building sand provides better binding properties and structural support for masonry. Understanding differences in grain size, purity, and application helps optimize material performance and project outcomes.

Glass Sand vs Building Sand Infographic

materialdif.com

materialdif.com