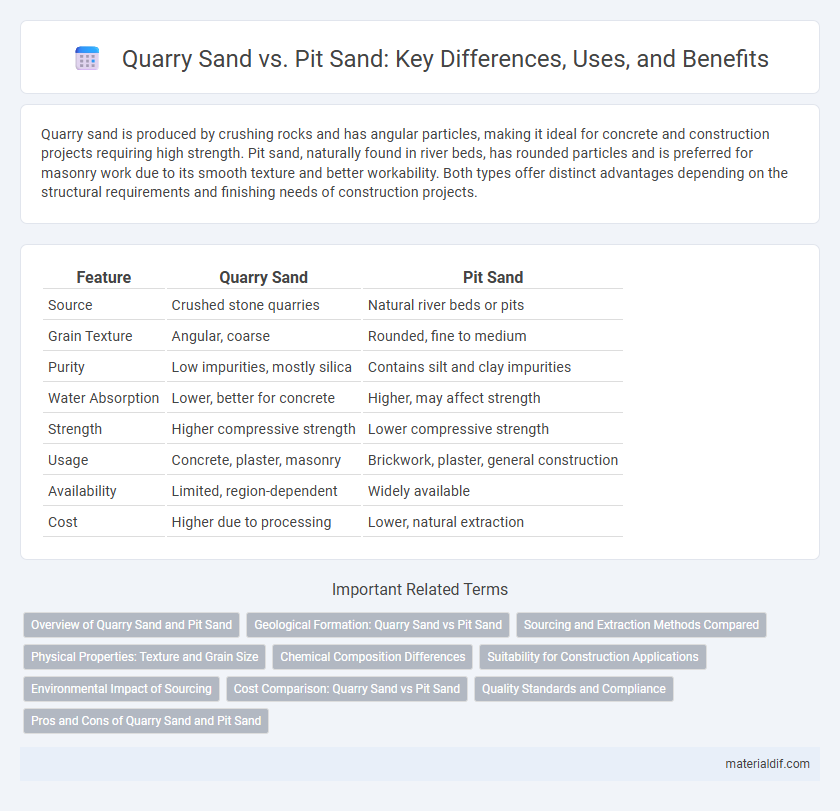

Quarry sand is produced by crushing rocks and has angular particles, making it ideal for concrete and construction projects requiring high strength. Pit sand, naturally found in river beds, has rounded particles and is preferred for masonry work due to its smooth texture and better workability. Both types offer distinct advantages depending on the structural requirements and finishing needs of construction projects.

Table of Comparison

| Feature | Quarry Sand | Pit Sand |

|---|---|---|

| Source | Crushed stone quarries | Natural river beds or pits |

| Grain Texture | Angular, coarse | Rounded, fine to medium |

| Purity | Low impurities, mostly silica | Contains silt and clay impurities |

| Water Absorption | Lower, better for concrete | Higher, may affect strength |

| Strength | Higher compressive strength | Lower compressive strength |

| Usage | Concrete, plaster, masonry | Brickwork, plaster, general construction |

| Availability | Limited, region-dependent | Widely available |

| Cost | Higher due to processing | Lower, natural extraction |

Overview of Quarry Sand and Pit Sand

Quarry sand is an artificial sand produced by crushing rocks in quarries, characterized by its angular particles and high strength properties, making it suitable for concrete and construction work. Pit sand, a natural sand obtained from river beds or pits, features smooth, rounded particles with good cohesiveness, ideal for plaster work and brick masonry. The choice between quarry sand and pit sand depends on the specific construction requirements, balancing factors such as particle shape, strength, and workability.

Geological Formation: Quarry Sand vs Pit Sand

Quarry sand is derived from crushing hard rocks like granite or basalt in quarry sites, resulting in angular particles with rough texture, while pit sand is naturally deposited in river beds, exhibiting rounded grains due to water erosion and sedimentation processes. Geological formation of quarry sand involves mechanical weathering of bedrock, producing coarser, sharper sand ideal for construction requiring better binding. In contrast, pit sand forms through fluvial action, leading to softer, more uniform grains favored for plastering and masonry works.

Sourcing and Extraction Methods Compared

Quarry sand is produced by crushing rocks in a quarry using mechanical processes like jaw crushers and vibrating screens, resulting in angular particles with consistent grading ideal for concrete. Pit sand is naturally sourced from riverbeds or pits, extracted using excavation tools and dredging methods, often containing rounder particles with higher water content and impurities. Quarry sand offers better quality control and reduced contamination due to controlled extraction, while pit sand availability depends on natural sediment deposits and seasonal variations.

Physical Properties: Texture and Grain Size

Quarry sand typically exhibits a coarse texture with angular grains, resulting from the crushing of rocks, which enhances its mechanical interlocking in concrete. Pit sand, derived from natural river beds, has a smooth texture with rounded grains, offering better workability but slightly lower strength compared to quarry sand. The grain size of quarry sand ranges from 4.75 mm to fine particles, whereas pit sand generally contains finer grains between 0.075 mm to 4.75 mm, influencing the overall sand grading and compaction characteristics in construction.

Chemical Composition Differences

Quarry sand primarily consists of silica (SiO2) with minimal impurities, resulting in a high percentage of quartz content, typically above 85%, which offers superior strength and durability in construction. Pit sand contains higher levels of iron oxide (Fe2O3) and aluminum oxide (Al2O3), giving it a characteristic reddish or yellowish hue, but lower silica content, generally around 70-75%, which affects its binding properties. The chemical composition differences influence their suitability in concrete work, with quarry sand favored for its chemical purity and pit sand valued for its better workability due to higher clay and silt content.

Suitability for Construction Applications

Quarry sand, known for its angular particles and higher strength, is highly suitable for concrete production and heavy construction due to better bonding with cement. Pit sand, with smoother grains and higher silt content, is preferred for plastering and masonry work where fine texture and workability matter. Understanding the distinct properties of quarry sand and pit sand ensures optimal choice in various construction applications to enhance durability and finish quality.

Environmental Impact of Sourcing

Quarry sand extraction involves crushing rocks, leading to habitat disruption and higher energy consumption, while pit sand is naturally deposited by riverbeds, causing less environmental degradation when sourced responsibly. Quarrying processes generate significant dust and noise pollution, contributing to local air and water quality issues. Pit sand sourcing risks riverbank erosion and groundwater depletion, impacting aquatic ecosystems and local communities.

Cost Comparison: Quarry Sand vs Pit Sand

Quarry sand generally costs more than pit sand due to the extensive crushing and screening processes involved in its production, leading to higher processing expenses. Pit sand is typically cheaper because it is naturally available and requires minimal processing, but it may contain impurities affecting its quality. Cost differences also depend on local availability, transportation expenses, and the intended construction application where specific sand properties are required.

Quality Standards and Compliance

Quarry sand typically adheres to stricter quality standards due to controlled crushing and screening processes, ensuring uniform particle size and minimal impurities. Pit sand, sourced directly from river beds, may contain organic matter and silt, leading to variable compliance with construction-grade specifications. Meeting standards like IS 383:2016 is essential for both sands to guarantee structural integrity and durability in concrete and masonry works.

Pros and Cons of Quarry Sand and Pit Sand

Quarry sand offers high strength and durability due to its angular particles and low silt content, making it ideal for concrete work, though its rough texture can reduce workability. Pit sand has a smoother texture and is more readily available, providing better workability in mortar mixes, but its high silt content can weaken structural strength and cause shrinkage cracks. While quarry sand enhances concrete quality, pit sand remains preferred for plastering due to ease of use and cost-effectiveness.

Quarry sand vs Pit sand Infographic

materialdif.com

materialdif.com