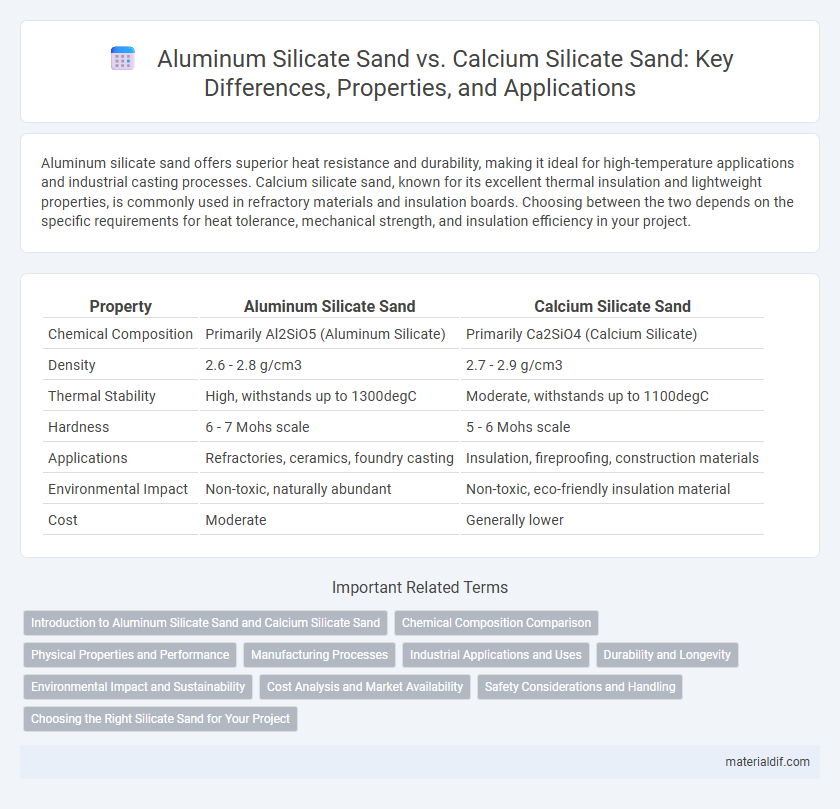

Aluminum silicate sand offers superior heat resistance and durability, making it ideal for high-temperature applications and industrial casting processes. Calcium silicate sand, known for its excellent thermal insulation and lightweight properties, is commonly used in refractory materials and insulation boards. Choosing between the two depends on the specific requirements for heat tolerance, mechanical strength, and insulation efficiency in your project.

Table of Comparison

| Property | Aluminum Silicate Sand | Calcium Silicate Sand |

|---|---|---|

| Chemical Composition | Primarily Al2SiO5 (Aluminum Silicate) | Primarily Ca2SiO4 (Calcium Silicate) |

| Density | 2.6 - 2.8 g/cm3 | 2.7 - 2.9 g/cm3 |

| Thermal Stability | High, withstands up to 1300degC | Moderate, withstands up to 1100degC |

| Hardness | 6 - 7 Mohs scale | 5 - 6 Mohs scale |

| Applications | Refractories, ceramics, foundry casting | Insulation, fireproofing, construction materials |

| Environmental Impact | Non-toxic, naturally abundant | Non-toxic, eco-friendly insulation material |

| Cost | Moderate | Generally lower |

Introduction to Aluminum Silicate Sand and Calcium Silicate Sand

Aluminum silicate sand, commonly used in foundry applications, consists primarily of aluminum oxide and silicon dioxide, providing excellent thermal stability and refractory properties. Calcium silicate sand, composed mainly of calcium oxide and silicon dioxide, offers superior insulation and fire resistance, frequently utilized in heat-resistant construction materials. Both types serve distinct industrial purposes due to their unique chemical compositions and physical characteristics.

Chemical Composition Comparison

Aluminum silicate sand primarily consists of Al2O3 (aluminum oxide) and SiO2 (silicon dioxide), offering high thermal resistance and stability, making it suitable for refractory applications. In contrast, calcium silicate sand contains significant amounts of CaO (calcium oxide) alongside SiO2, providing excellent insulation properties and moisture resistance. The higher aluminum oxide content in aluminum silicate sand enhances durability, whereas the calcium content in calcium silicate sand improves lightness and fireproofing characteristics.

Physical Properties and Performance

Aluminum silicate sand exhibits higher thermal resistance and improved durability compared to calcium silicate sand, making it ideal for high-temperature applications. Its finer grain size and higher refractoriness contribute to better mold strength and surface finish in casting processes. Calcium silicate sand, while having lower density and higher porosity, offers excellent insulation properties and moisture resistance, which are advantageous in refractory and insulation uses.

Manufacturing Processes

Aluminum silicate sand, primarily composed of kaolinite, undergoes a refining process involving crushing, washing, and calcination to enhance purity and particle size for industrial applications. Calcium silicate sand is typically produced through a chemical precipitation method, combining calcium ions with silicate ions, followed by drying and milling to achieve the desired granulometry. These distinct manufacturing processes directly influence the sands' physical properties and suitability for diverse uses such as refractory materials and insulation.

Industrial Applications and Uses

Aluminum silicate sand is prized in industrial applications such as refractory linings, ceramics, and insulation materials due to its high melting point and thermal stability. Calcium silicate sand finds extensive use in construction and insulation industries for fireproofing, acoustic panels, and lightweight structural materials because of its excellent heat resistance and moisture absorption. The choice between aluminum silicate and calcium silicate sands depends on specific performance requirements like thermal endurance, durability, and moisture handling in manufacturing processes.

Durability and Longevity

Aluminum silicate sand exhibits superior durability due to its higher resistance to thermal decomposition and chemical weathering, making it ideal for high-temperature applications and prolonged exposure to harsh environments. Calcium silicate sand offers moderate durability but tends to degrade faster when subjected to moisture and acidic conditions, limiting its longevity in outdoor or industrial settings. The inherent chemical structure of aluminum silicate ensures long-term stability, outperforming calcium silicate in maintaining mechanical integrity over extended periods.

Environmental Impact and Sustainability

Aluminum silicate sand, commonly derived from kaolin clay, exhibits lower environmental impact due to its natural occurrence and minimal processing requirements compared to calcium silicate sand, which often involves energy-intensive manufacturing. The biodegradability and lower dust emissions of aluminum silicate contribute to enhanced sustainability, whereas calcium silicate sand's production can result in higher carbon footprints and waste generation. Selecting aluminum silicate sand supports greener industrial practices by reducing resource depletion and promoting recyclability in applications such as filtration, ceramics, and construction.

Cost Analysis and Market Availability

Aluminum silicate sand typically commands a higher price than calcium silicate sand due to its superior heat resistance and durability, making it favored in specialized industrial applications. Calcium silicate sand is generally more affordable and widely available, benefiting from abundant natural deposits and simpler processing methods. Market availability for aluminum silicate sand is more limited, often sourced from specific mining regions, whereas calcium silicate sand enjoys broad distribution channels and easier access globally.

Safety Considerations and Handling

Aluminum silicate sand contains fine particles that can pose respiratory hazards, requiring the use of protective masks and proper ventilation during handling. Calcium silicate sand is generally less abrasive but may cause skin irritation, so wearing gloves and avoiding dust inhalation is essential. Both materials demand adherence to safety data sheets (SDS) guidelines and workplace exposure limits to minimize health risks.

Choosing the Right Silicate Sand for Your Project

Aluminum silicate sand offers superior heat resistance and durability, making it ideal for high-temperature industrial applications such as foundries and refractory linings. Calcium silicate sand provides better insulation and lightweight properties, suitable for construction projects requiring thermal efficiency and fireproofing. Selecting the right silicate sand depends on the specific requirements of heat tolerance, insulation, and structural strength for your project.

Aluminum Silicate Sand vs Calcium Silicate Sand Infographic

materialdif.com

materialdif.com