Recycled sand offers an eco-friendly alternative to virgin sand by reducing the demand for natural resource extraction and minimizing construction waste. It often undergoes processing to meet quality standards, making it suitable for various applications such as concrete production and landscaping. While virgin sand typically provides consistent particle size and purity, recycled sand supports sustainable building practices without significantly compromising performance.

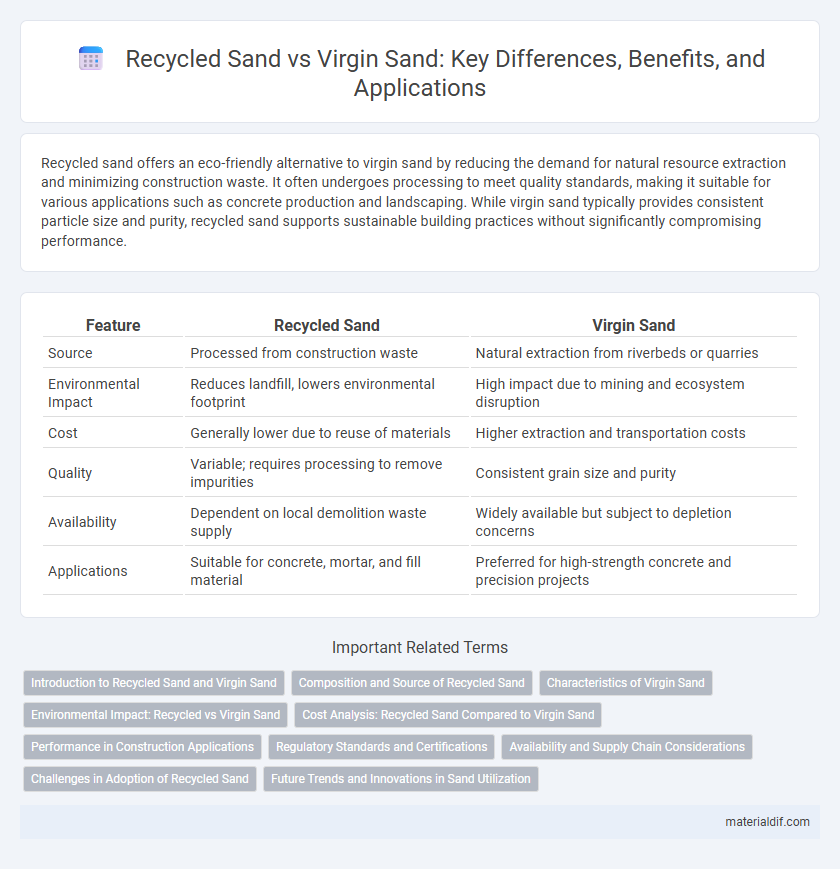

Table of Comparison

| Feature | Recycled Sand | Virgin Sand |

|---|---|---|

| Source | Processed from construction waste | Natural extraction from riverbeds or quarries |

| Environmental Impact | Reduces landfill, lowers environmental footprint | High impact due to mining and ecosystem disruption |

| Cost | Generally lower due to reuse of materials | Higher extraction and transportation costs |

| Quality | Variable; requires processing to remove impurities | Consistent grain size and purity |

| Availability | Dependent on local demolition waste supply | Widely available but subject to depletion concerns |

| Applications | Suitable for concrete, mortar, and fill material | Preferred for high-strength concrete and precision projects |

Introduction to Recycled Sand and Virgin Sand

Recycled sand is produced by processing and crushing construction and demolition waste, offering an eco-friendly alternative that reduces the demand for natural resources. Virgin sand, on the other hand, is naturally mined from quarries and riverbeds, characterized by its purity and consistent grain size ideal for high-strength concrete and masonry. The use of recycled sand supports sustainable construction practices, while virgin sand provides reliable performance in traditional building applications.

Composition and Source of Recycled Sand

Recycled sand primarily consists of crushed concrete, masonry, and industrial byproducts, making its composition more variable compared to virgin sand, which is mainly composed of natural quartz or silica particles. The source of recycled sand originates from construction and demolition waste processed through crushing and screening, whereas virgin sand is extracted through mining from natural deposits like riverbeds or quarries. This difference in origin impacts the physical and chemical properties, influencing the suitability of recycled sand for specific construction applications.

Characteristics of Virgin Sand

Virgin sand is characterized by its natural purity, consistent grain size, and angular texture, which enhance its binding properties in construction applications. Its uncontaminated composition ensures superior strength and durability in concrete and mortar mixtures. Unlike recycled sand, virgin sand has minimal impurities, resulting in higher quality and predictable performance in structural projects.

Environmental Impact: Recycled vs Virgin Sand

Recycled sand significantly reduces environmental impact by lowering the demand for virgin sand extraction, which often leads to habitat destruction, groundwater depletion, and increased carbon emissions from mining activities. Using recycled sand conserves natural resources and decreases landfill waste, promoting sustainable construction practices. Virgin sand extraction contributes to ecosystem degradation, whereas recycled sand supports circular economy principles and reduces overall ecological footprint.

Cost Analysis: Recycled Sand Compared to Virgin Sand

Recycled sand typically costs 20-40% less than virgin sand due to lower sourcing and extraction expenses, significantly reducing overall project budgets. The price advantage is amplified in regions with stringent environmental regulations and high transportation costs for virgin sand. While recycled sand may require additional processing to match the quality of virgin sand, the cost savings make it an economically viable alternative for many construction applications.

Performance in Construction Applications

Recycled sand offers comparable compressive strength and durability to virgin sand in construction applications, making it a viable alternative for concrete and mortar production. Its angular particle shape improves bonding properties, enhancing structural integrity in masonry work. However, careful quality control is essential to minimize impurities and maintain consistent performance standards.

Regulatory Standards and Certifications

Recycled sand must comply with strict regulatory standards such as ASTM C33 and EN 12620 to ensure suitability for construction applications, often requiring additional testing for contaminants like heavy metals and organic matter. Virgin sand typically meets established certifications more consistently due to its natural, unprocessed origin, offering predictable particle size distribution and purity. Compliance with ISO 14001 environmental management standards increasingly influences the certification process for both recycled and virgin sand, promoting sustainability and environmental responsibility.

Availability and Supply Chain Considerations

Recycled sand offers increased availability by utilizing construction and demolition waste, reducing dependence on limited natural resources compared to virgin sand, which faces depletion risks due to extensive mining. The supply chain for recycled sand is often more localized, minimizing transportation costs and environmental impact, whereas virgin sand requires extraction from distant quarries, leading to longer, more complex supply routes. Variability in recycled sand quality necessitates stringent processing standards to ensure consistent performance, whereas virgin sand typically provides uniform properties due to established sourcing processes.

Challenges in Adoption of Recycled Sand

Recycled sand faces challenges in adoption due to inconsistent particle size distribution and the presence of impurities affecting the quality and strength of construction materials. Variability in the chemical composition of recycled sand can lead to durability issues, limiting its application in high-performance concrete. Regulatory standards and lack of industry-wide acceptance further hinder widespread use compared to virgin sand.

Future Trends and Innovations in Sand Utilization

Future trends in sand utilization emphasize sustainable alternatives like recycled sand to reduce environmental degradation caused by virgin sand extraction. Innovations in processing technologies enhance the purity and performance of recycled sand, making it a viable option for construction and industrial applications. Emerging standards and regulations promote increased adoption of recycled sand, driving research into more efficient recycling methods and broader market integration.

Recycled sand vs Virgin sand Infographic

materialdif.com

materialdif.com