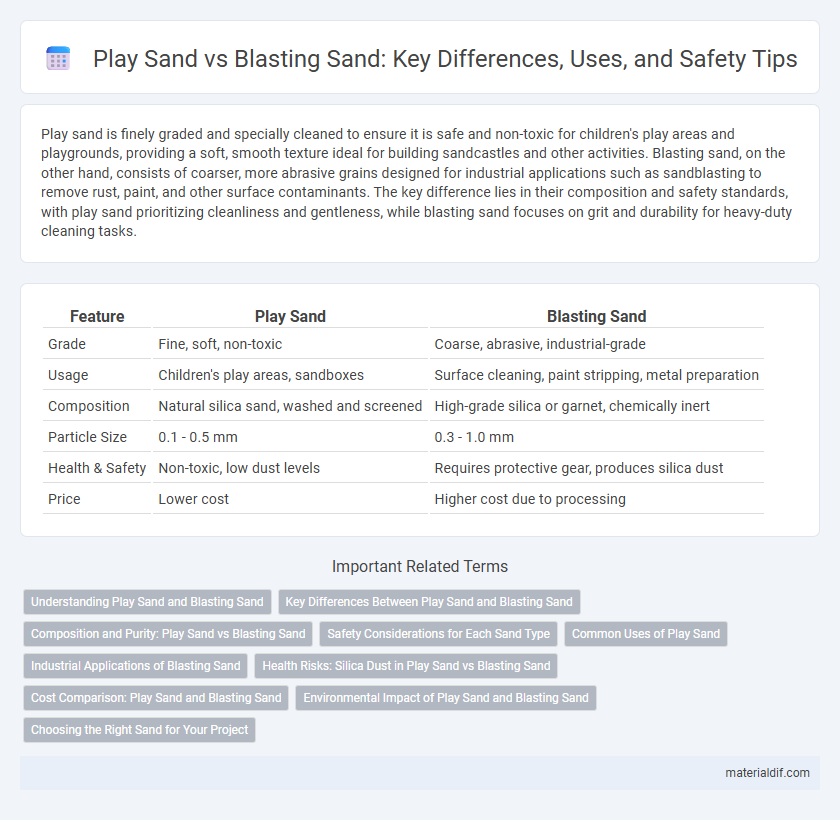

Play sand is finely graded and specially cleaned to ensure it is safe and non-toxic for children's play areas and playgrounds, providing a soft, smooth texture ideal for building sandcastles and other activities. Blasting sand, on the other hand, consists of coarser, more abrasive grains designed for industrial applications such as sandblasting to remove rust, paint, and other surface contaminants. The key difference lies in their composition and safety standards, with play sand prioritizing cleanliness and gentleness, while blasting sand focuses on grit and durability for heavy-duty cleaning tasks.

Table of Comparison

| Feature | Play Sand | Blasting Sand |

|---|---|---|

| Grade | Fine, soft, non-toxic | Coarse, abrasive, industrial-grade |

| Usage | Children's play areas, sandboxes | Surface cleaning, paint stripping, metal preparation |

| Composition | Natural silica sand, washed and screened | High-grade silica or garnet, chemically inert |

| Particle Size | 0.1 - 0.5 mm | 0.3 - 1.0 mm |

| Health & Safety | Non-toxic, low dust levels | Requires protective gear, produces silica dust |

| Price | Lower cost | Higher cost due to processing |

Understanding Play Sand and Blasting Sand

Play sand is specifically designed for safe, non-toxic use in children's sandboxes and playgrounds, characterized by fine, smooth grains that minimize skin irritation and support creative play. Blasting sand, composed of coarser, angular grains, is engineered for industrial abrasive blasting applications, providing effective surface preparation by removing rust, paint, and debris from metal or concrete surfaces. Understanding the distinct physical properties and safety standards of play sand versus blasting sand ensures appropriate usage tailored to either recreational or industrial needs.

Key Differences Between Play Sand and Blasting Sand

Play sand is a fine, clean, and safe type of sand specifically designed for children's play areas, featuring smooth, non-toxic granules that minimize respiratory risks. Blasting sand consists of coarser, angular particles with high hardness used primarily for abrasive cleaning and surface preparation in industrial settings, often containing silica which requires careful handling. The key differences lie in particle size, safety standards, and intended use, with play sand prioritizing safety and softness, while blasting sand emphasizes durability and abrasiveness.

Composition and Purity: Play Sand vs Blasting Sand

Play sand typically consists of fine, smooth silica particles with minimal impurities, ensuring safety and comfort for children's use. Blasting sand, often sourced from coarser silica or other mineral mixes, contains higher levels of impurities and abrasive materials designed for industrial cleaning and surface preparation. The purity of play sand prioritizes non-toxic, dust-free characteristics, whereas blasting sand's composition emphasizes durability and effectiveness in abrasive applications.

Safety Considerations for Each Sand Type

Play sand is specifically processed to be free of harmful contaminants and is finely screened to minimize dust, making it safer for children's recreational use. Blasting sand, often containing sharp angular particles and possible silica dust, poses inhalation risks and requires protective equipment like masks and goggles during use. Proper ventilation and adherence to safety guidelines are crucial to prevent respiratory issues and skin irritation when handling blasting sand.

Common Uses of Play Sand

Play sand is primarily used in children's sandboxes, playgrounds, and indoor play areas due to its fine texture and non-toxic properties, ensuring safety during play. Unlike blasting sand, which is coarse and abrasive for industrial cleaning and surface preparation, play sand is designed to be soft and easy to mold, promoting creativity and sensory development. Its common applications also extend to educational activities, arts and crafts, and therapeutic sensory bins.

Industrial Applications of Blasting Sand

Blasting sand is commonly used in industrial applications for abrasive blasting to clean, smooth, or shape metal surfaces, remove rust, paint, and other contaminants. Its angular grains provide superior cutting and cleaning efficiency compared to the rounded grains of play sand, which lacks the hardness and angularity needed for effective abrasive action. Industrial-grade blasting sand is specially processed to ensure consistent particle size and durability, making it ideal for surface preparation in automotive, construction, and manufacturing industries.

Health Risks: Silica Dust in Play Sand vs Blasting Sand

Play sand contains fine silica particles that, when inhaled in large amounts over time, pose mild respiratory irritation risks, especially for children playing. Blasting sand, composed of angular silica grains, generates higher concentrations of respirable crystalline silica dust, significantly increasing the risk of silicosis and other severe lung diseases for industrial workers. Proper protective equipment and ventilation measures are critical to mitigate health hazards associated with silica dust exposure in blasting environments.

Cost Comparison: Play Sand and Blasting Sand

Play sand typically costs between $20 to $30 per 50-pound bag, making it a budget-friendly option for children's play areas and landscaping. Blasting sand, designed for industrial applications like sandblasting, is priced higher, ranging from $50 to $100 per ton due to its specialized cleanliness and granule size. The significant cost difference reflects the distinct purposes and quality standards required for each type of sand.

Environmental Impact of Play Sand and Blasting Sand

Play sand, typically sourced from natural, clean silica deposits, poses minimal environmental impact due to its non-toxic composition and biodegradability, making it safe for recreational use and soil integration. In contrast, blasting sand, often containing abrasive elements and potential contaminants like crystalline silica, can result in hazardous dust emissions and ecological disturbances when improperly disposed of, contributing to air and water pollution. Sustainable practices in sourcing and recycling blasting sand are crucial to mitigating its environmental footprint.

Choosing the Right Sand for Your Project

Play sand is specifically processed to be clean, fine, and safe for children's use in playgrounds or sandboxes, making it ideal for activities requiring softness and non-toxicity. Blasting sand, on the other hand, features abrasive properties with angular grains designed for surface cleaning and stripping, suitable for industrial or construction projects. Selecting the right sand depends on the project's requirements for safety, texture, and functionality--play sand for recreational use and blasting sand for heavy-duty cleaning tasks.

Play sand vs Blasting sand Infographic

materialdif.com

materialdif.com