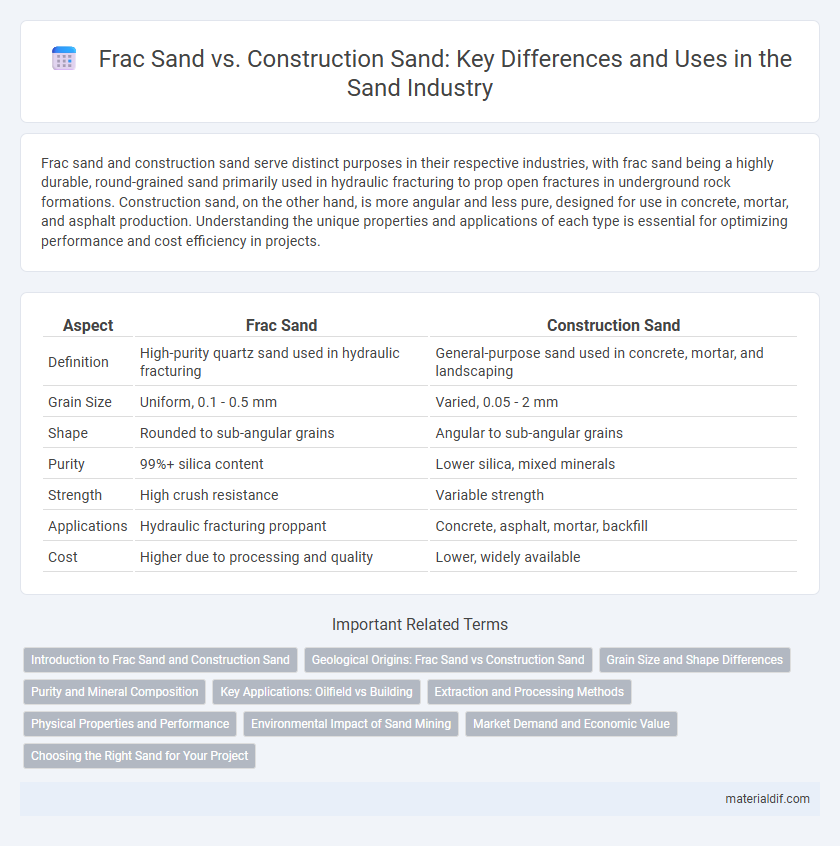

Frac sand and construction sand serve distinct purposes in their respective industries, with frac sand being a highly durable, round-grained sand primarily used in hydraulic fracturing to prop open fractures in underground rock formations. Construction sand, on the other hand, is more angular and less pure, designed for use in concrete, mortar, and asphalt production. Understanding the unique properties and applications of each type is essential for optimizing performance and cost efficiency in projects.

Table of Comparison

| Aspect | Frac Sand | Construction Sand |

|---|---|---|

| Definition | High-purity quartz sand used in hydraulic fracturing | General-purpose sand used in concrete, mortar, and landscaping |

| Grain Size | Uniform, 0.1 - 0.5 mm | Varied, 0.05 - 2 mm |

| Shape | Rounded to sub-angular grains | Angular to sub-angular grains |

| Purity | 99%+ silica content | Lower silica, mixed minerals |

| Strength | High crush resistance | Variable strength |

| Applications | Hydraulic fracturing proppant | Concrete, asphalt, mortar, backfill |

| Cost | Higher due to processing and quality | Lower, widely available |

Introduction to Frac Sand and Construction Sand

Frac sand, characterized by its high-purity quartz composition and uniform grain size, is essential for hydraulic fracturing in oil and gas extraction due to its strength and permeability. Construction sand, typically sourced from riverbeds or quarries, has varied grain sizes and compositions tailored for use in concrete, mortar, and road building. Understanding the distinct properties and functions of frac sand versus construction sand is crucial for selecting the appropriate material in industrial and infrastructure projects.

Geological Origins: Frac Sand vs Construction Sand

Frac sand originates from highly durable quartz sandstone formations, primarily from the Cambrian age, known for its high silica content and round, crush-resistant grains ideal for hydraulic fracturing. Construction sand derives from various sedimentary sources including riverbeds, glacial deposits, and beaches, consisting of a mix of mineral compositions and less uniform grain shapes suited for concrete and masonry applications. The geological origins of frac sand ensure consistent particle size and strength, while construction sand's broader sources result in variable grain characteristics tailored for diverse building needs.

Grain Size and Shape Differences

Frac sand features uniform, spherical grains ranging between 0.15 to 0.3 millimeters, optimized for creating high permeability in hydraulic fracturing. Construction sand typically exhibits a wider grain size distribution from 0.06 to 2 millimeters with angular or sub-angular shapes, enhancing compaction and stability in concrete mixtures. These distinct grain size and shape characteristics directly influence their suitability for industrial applications in oil extraction versus building materials.

Purity and Mineral Composition

Frac sand consists primarily of high-purity quartz, typically over 99% silica, ensuring exceptional strength and roundness for hydraulic fracturing. Construction sand has a more varied mineral composition, including quartz, feldspar, and mica, resulting in lower purity and different mechanical properties. The high quartz content in frac sand enhances its durability and permeability, making it essential for proppant use in oil and gas extraction.

Key Applications: Oilfield vs Building

Frac sand is primarily used in hydraulic fracturing to prop open fractures in oil and gas wells, enhancing hydrocarbon extraction with high-purity, crush-resistant quartz sand. Construction sand, with its coarse texture and variable composition, is essential for concrete production, mortar, and road base materials in building projects. The distinct granulometry and mineralogy differentiate frac sand's role in oilfield operations from construction sand's application in structural development.

Extraction and Processing Methods

Frac sand is extracted through mining techniques that prioritize high-purity quartz with specific grain size and roundness, requiring extensive washing, drying, and sorting processes to meet stringent hydraulic fracturing standards. Construction sand is typically obtained from natural sand deposits like riverbeds or quarries, involving basic screening and washing to remove impurities suitable for concrete and mortar applications. The processing of frac sand demands advanced separation and quality control technologies, while construction sand undergoes minimal refinement tailored to general building requirements.

Physical Properties and Performance

Frac sand is characterized by its high purity, spherical shape, and consistent grain size, making it highly durable and ideal for hydraulic fracturing applications due to superior permeability and strength under pressure. Construction sand often has varying grain sizes and angular particles, providing excellent compaction and stability for concrete and masonry but lower resistance to abrasion and crushing compared to frac sand. The physical properties of frac sand optimize fluid flow and proppant placement in fractures, while construction sand prioritizes workability and load-bearing capacity in building materials.

Environmental Impact of Sand Mining

Frac sand mining generates significant environmental concerns due to habitat disruption, water usage, and silica dust pollution, posing risks to local ecosystems and human health. Construction sand mining also impacts riverbeds and coastal areas, leading to erosion, loss of biodiversity, and altered hydrology. Sustainable practices and stringent regulations are essential to mitigate environmental degradation associated with both frac and construction sand extraction.

Market Demand and Economic Value

Frac sand dominates the energy sector with high market demand driven by hydraulic fracturing in oil and gas extraction, commanding premium pricing due to its specialized properties like high purity and crush resistance. Construction sand experiences consistent demand in infrastructure and residential projects, with its economic value tied to volume and local availability rather than specialized characteristics. The economic disparity arises as frac sand's scarcity and technical specifications enhance profitability, whereas construction sand benefits from broad application but lower price margins.

Choosing the Right Sand for Your Project

Frac sand, characterized by its high purity, roundness, and strength, is specifically engineered for hydraulic fracturing to keep rock fractures open and maximize oil and gas extraction. Construction sand, often coarser with variable grain sizes, is suitable for concrete, mortar, and road base applications where structural stability and compaction are essential. Selecting the right sand depends on the project's purpose, with frac sand prioritized for energy sectors requiring durability under pressure, while construction sand meets the diverse demands of building and infrastructure projects.

Frac sand vs Construction sand Infographic

materialdif.com

materialdif.com