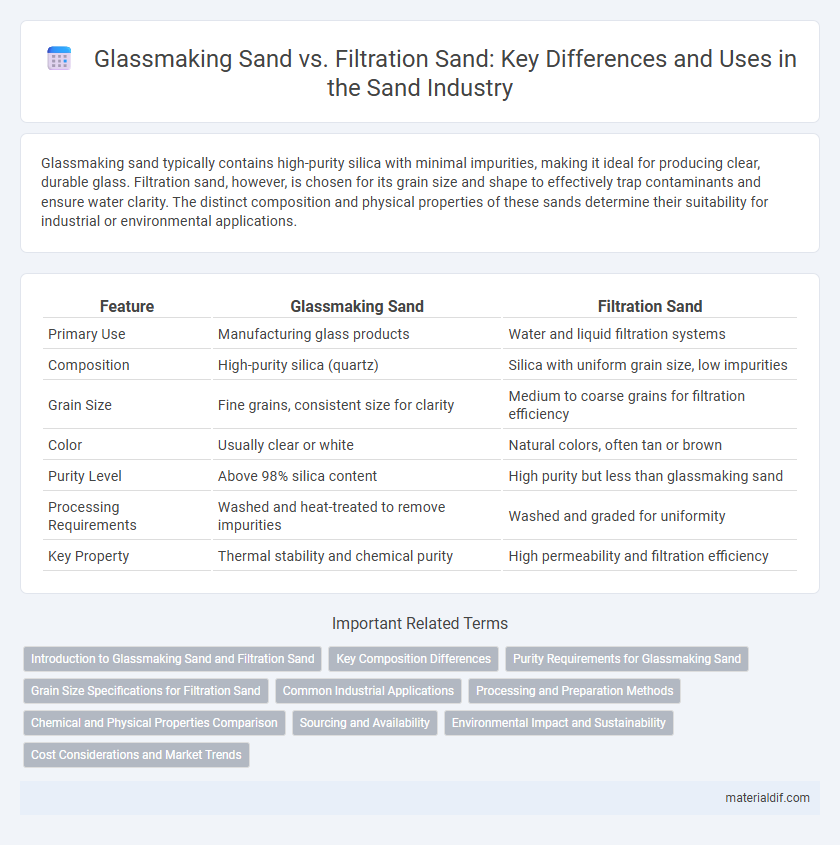

Glassmaking sand typically contains high-purity silica with minimal impurities, making it ideal for producing clear, durable glass. Filtration sand, however, is chosen for its grain size and shape to effectively trap contaminants and ensure water clarity. The distinct composition and physical properties of these sands determine their suitability for industrial or environmental applications.

Table of Comparison

| Feature | Glassmaking Sand | Filtration Sand |

|---|---|---|

| Primary Use | Manufacturing glass products | Water and liquid filtration systems |

| Composition | High-purity silica (quartz) | Silica with uniform grain size, low impurities |

| Grain Size | Fine grains, consistent size for clarity | Medium to coarse grains for filtration efficiency |

| Color | Usually clear or white | Natural colors, often tan or brown |

| Purity Level | Above 98% silica content | High purity but less than glassmaking sand |

| Processing Requirements | Washed and heat-treated to remove impurities | Washed and graded for uniformity |

| Key Property | Thermal stability and chemical purity | High permeability and filtration efficiency |

Introduction to Glassmaking Sand and Filtration Sand

Glassmaking sand is characterized by its high silica content, typically over 95%, ensuring clarity and durability in glass production. Filtration sand, in contrast, possesses uniform grain size and high purity to efficiently remove impurities from liquids in water treatment processes. Both types of sand are essential industrial materials, distinguished primarily by their chemical composition and granulometry to suit their specific applications.

Key Composition Differences

Glassmaking sand primarily consists of high-purity silica (SiO2) with minimal impurities such as iron oxide and alumina, ensuring clarity and strength in glass production. Filtration sand contains a broader mix of minerals, including quartz, feldspar, and mica, designed to optimize particle size distribution and flow rate for effective water filtration. The chemical purity of glassmaking sand is crucial for melting efficiency and glass quality, whereas filtration sand's composition prioritizes mechanical properties and porosity.

Purity Requirements for Glassmaking Sand

Glassmaking sand requires an exceptionally high purity level, typically containing over 95% silica (SiO2) with minimal iron oxide and other impurities to ensure clarity and strength in the final glass product. Filtration sand has more relaxed purity standards, often tolerating higher levels of contaminants since its primary function is mechanical filtration rather than optical clarity or chemical stability. The stringent purity requirements for glassmaking sand are critical to preventing discoloration and defects during the melting and forming processes in glass production.

Grain Size Specifications for Filtration Sand

Filtration sand requires precise grain size specifications, typically ranging from 0.45 mm to 0.55 mm, to ensure optimal permeability and effective removal of contaminants in water treatment processes. In contrast, glassmaking sand demands a finer grain size, often between 0.1 mm to 0.25 mm, to achieve the high purity and clarity essential for glass production. Proper grain size distribution in filtration sand enhances backwashing efficiency and prevents clogging in filtration systems.

Common Industrial Applications

Glassmaking sand, primarily composed of high-purity silica, is essential for producing clear, strong glass in industries such as automotive manufacturing, architectural glazing, and container production. Filtration sand, commonly made from well-rounded quartz grains, is widely used in water treatment plants, swimming pool filters, and industrial wastewater management due to its effective particle removal capabilities. The distinct grain size and purity levels in these sands directly influence their suitability for specific industrial applications, ensuring optimal performance and quality control.

Processing and Preparation Methods

Glassmaking sand undergoes rigorous washing, sorting, and chemical treatments to remove impurities such as iron and organic matter, ensuring high silica content and clarity essential for glass production. Filtration sand is processed through thorough washing, grading, and drying to achieve uniform grain size and remove fines, optimizing permeability and filtration efficiency. Both types of sand require precise processing to meet industry-specific standards, with glassmaking sand emphasizing purity and filtration sand focusing on particle uniformity.

Chemical and Physical Properties Comparison

Glassmaking sand typically contains high-purity silica (SiO2) with minimal impurities like iron oxide, ensuring clarity and strength in glass production. Filtration sand has a more varied composition, often including quartz and other minerals, and is characterized by a specific grain size and shape that optimize water flow and contaminant removal. The chemical uniformity and low impurity levels in glassmaking sand contrast with the coarser, multi-mineral nature of filtration sand, reflecting their distinct functional requirements.

Sourcing and Availability

Glassmaking sand primarily derives from high-purity silica deposits characterized by uniform grain size and minimal impurities, often sourced from specialized quarries in regions like the United States and Australia. Filtration sand requires coarser grains with high durability, commonly obtained from riverbeds and dune formations abundant in many parts of Europe and Asia. The availability of glassmaking sand is more limited due to stringent quality requirements, whereas filtration sand is more widely accessible with fewer processing constraints.

Environmental Impact and Sustainability

Glassmaking sand, primarily composed of high-purity silica, demands extensive mining and processing that can disrupt ecosystems and consume significant energy, raising environmental concerns. Filtration sand, often sourced from abundant natural deposits with less refinement, typically has a lower ecological footprint but still requires responsible extraction to avoid habitat degradation. Sustainable practices in both sectors include recycling glass materials and implementing regulated mining to minimize landscape disturbance and promote long-term resource availability.

Cost Considerations and Market Trends

Glassmaking sand typically demands high purity silica content, driving up costs due to rigorous processing and quality control compared to filtration sand, which requires lower purity and is more readily available. Market trends indicate increasing demand for glassmaking sand driven by expanding glass and electronics industries, resulting in price volatility and supply chain challenges. Filtration sand markets remain stable with steady demand from water treatment and construction sectors, offering more predictable pricing and broader supplier options.

Glassmaking Sand vs Filtration Sand Infographic

materialdif.com

materialdif.com