Fused silica is a high-purity, non-crystalline form of silicon dioxide with superior thermal shock resistance and low thermal expansion compared to quartz sand, which is crystalline and contains impurities. Quartz sand is commonly used in construction and glassmaking, whereas fused silica is preferred in advanced optical and semiconductor applications due to its exceptional clarity and durability. The differences in microstructure and purity make fused silica more suitable for environments requiring high precision and resistance to thermal stress.

Table of Comparison

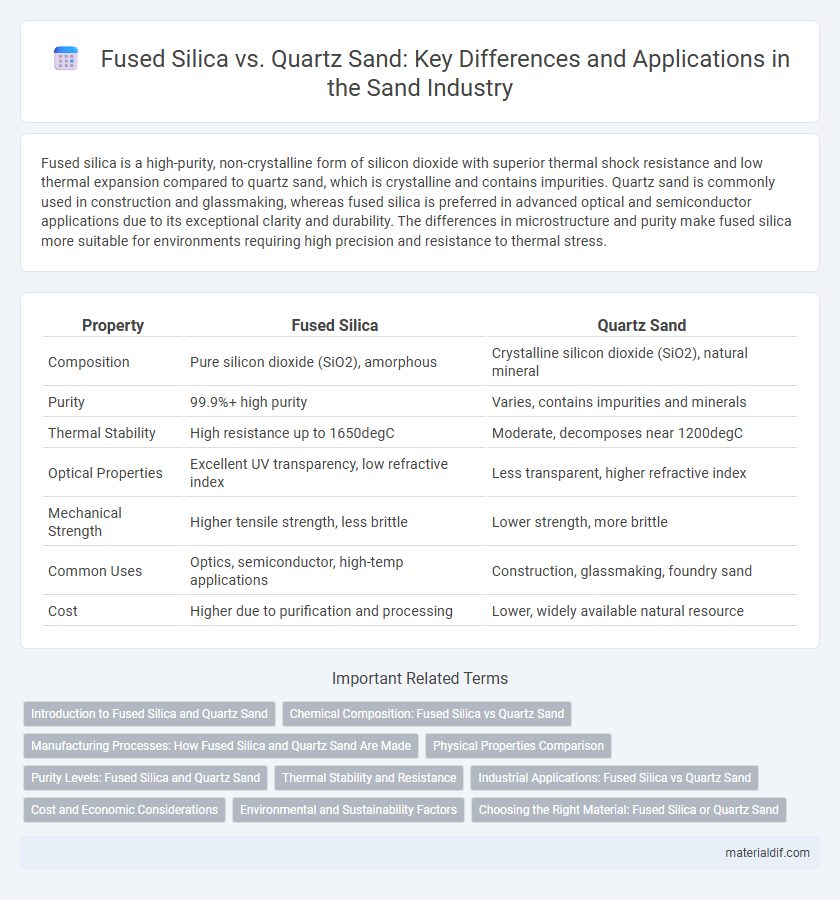

| Property | Fused Silica | Quartz Sand |

|---|---|---|

| Composition | Pure silicon dioxide (SiO2), amorphous | Crystalline silicon dioxide (SiO2), natural mineral |

| Purity | 99.9%+ high purity | Varies, contains impurities and minerals |

| Thermal Stability | High resistance up to 1650degC | Moderate, decomposes near 1200degC |

| Optical Properties | Excellent UV transparency, low refractive index | Less transparent, higher refractive index |

| Mechanical Strength | Higher tensile strength, less brittle | Lower strength, more brittle |

| Common Uses | Optics, semiconductor, high-temp applications | Construction, glassmaking, foundry sand |

| Cost | Higher due to purification and processing | Lower, widely available natural resource |

Introduction to Fused Silica and Quartz Sand

Fused silica is a high-purity amorphous form of silicon dioxide with superior thermal stability and low thermal expansion, making it ideal for precision optical and semiconductor applications. Quartz sand, primarily composed of crystalline silicon dioxide, is a naturally occurring material widely used in construction, glass manufacturing, and foundry molds due to its abundance and hardness. The key distinction lies in fused silica's production through melting and rapid cooling processes, resulting in a non-crystalline structure with enhanced durability compared to the crystalline nature of quartz sand.

Chemical Composition: Fused Silica vs Quartz Sand

Fused silica primarily consists of pure silicon dioxide (SiO2) with an amorphous, non-crystalline structure, offering superior chemical purity compared to quartz sand, which contains crystalline silica along with impurities such as aluminum oxide, iron oxide, and other trace minerals. The chemical composition of fused silica results in higher thermal stability and chemical resistance, making it suitable for advanced technological applications, whereas quartz sand's varied mineral content limits its use to construction and industrial processes. Differences in impurity levels significantly impact the optical clarity and thermal expansion properties between fused silica and quartz sand.

Manufacturing Processes: How Fused Silica and Quartz Sand Are Made

Fused silica is manufactured through the melting of high-purity quartz crystals at temperatures above 2000degC, resulting in an amorphous, non-crystalline structure with superior thermal and chemical stability. Quartz sand originates from natural silica deposits, consisting primarily of crystalline silicon dioxide, and is processed by washing, drying, and sometimes milling to achieve desired granularity for industrial applications. The high-temperature melting process of fused silica eliminates impurities and crystallinity, distinguishing it from the mechanically refined and sorted quartz sand used in glassmaking, foundry molds, and construction.

Physical Properties Comparison

Fused silica exhibits a higher purity level with over 99.9% silicon dioxide (SiO2) content, resulting in superior thermal stability and a melting point above 1650degC compared to quartz sand's melting point around 1713degC. Quartz sand, primarily composed of crystalline SiO2, has a density of approximately 2.65 g/cm3, whereas fused silica has a lower density near 2.2 g/cm3, contributing to its enhanced optical transparency and lower thermal expansion coefficient. The amorphous structure of fused silica provides a near-zero thermal expansion coefficient (around 0.5 x 10-6/K) versus quartz sand's higher expansion values, making fused silica ideal for high-precision and high-temperature applications.

Purity Levels: Fused Silica and Quartz Sand

Fused silica exhibits purity levels exceeding 99.9%, making it ideal for high-precision optical applications due to its minimal impurities and low thermal expansion. Quartz sand typically contains 95-98% silicon dioxide with variable impurities such as iron oxides, affecting its clarity and suitability for specialized uses. The superior purity of fused silica results from its synthetic production methods, distinguishing it from naturally sourced quartz sand.

Thermal Stability and Resistance

Fused silica exhibits superior thermal stability and resistance compared to quartz sand, with a melting point above 1,600degC and minimal thermal expansion, making it ideal for high-temperature applications. Quartz sand undergoes phase transitions at approximately 573degC, which can cause structural changes and reduced durability under thermal stress. This makes fused silica the preferred material in environments requiring consistent performance under extreme heat and thermal cycling.

Industrial Applications: Fused Silica vs Quartz Sand

Fused silica offers superior thermal stability and lower thermal expansion compared to quartz sand, making it ideal for high-temperature industrial applications such as semiconductor manufacturing, optical components, and high-performance glass production. Quartz sand is widely used in industries like foundry casting, glassmaking, and construction due to its abundant availability and lower cost. The choice between fused silica and quartz sand depends on the required purity, thermal resistance, and mechanical properties for specific industrial processes.

Cost and Economic Considerations

Fused silica commands a higher market price compared to quartz sand due to its superior purity and thermal stability, making it ideal for specialized industrial applications such as semiconductor manufacturing and high-performance optics. Quartz sand, abundant and widely available, offers a cost-effective alternative for general construction and glass-making processes where extreme purity is not critical. Economic decision-making hinges on balancing fused silica's premium cost against its enhanced performance benefits, while quartz sand remains the preferred choice for large-scale, budget-sensitive projects.

Environmental and Sustainability Factors

Fused silica offers superior environmental benefits compared to quartz sand due to its high purity and energy-efficient production processes that generate fewer greenhouse gas emissions. Quartz sand extraction often leads to habitat disruption and increased water usage, whereas fused silica manufacturing emphasizes recycling and reduced resource consumption, promoting sustainability. Choosing fused silica over quartz sand supports eco-friendly industrial practices by lowering environmental impact and conserving natural resources.

Choosing the Right Material: Fused Silica or Quartz Sand

Fused silica offers superior thermal resistance and low thermal expansion, making it ideal for high-temperature applications, while quartz sand provides greater availability and cost-effectiveness for construction and industrial uses. The high purity and amorphous structure of fused silica result in better optical and chemical stability compared to the crystalline form of quartz sand. Selecting between fused silica and quartz sand depends on the specific requirements for durability, thermal performance, and budget constraints in the intended application.

Fused silica vs Quartz sand Infographic

materialdif.com

materialdif.com