Silica sand, composed primarily of quartz, is known for its high purity, durability, and excellent thermal resistance, making it ideal for foundry molds and glass manufacturing. Chromite sand contains iron and chrome oxides, offering superior thermal conductivity and resistance to metal penetration, which enhances mold strength and casting quality. Choosing between silica and chromite sand depends on the specific requirements of the casting process, such as thermal properties and surface finish.

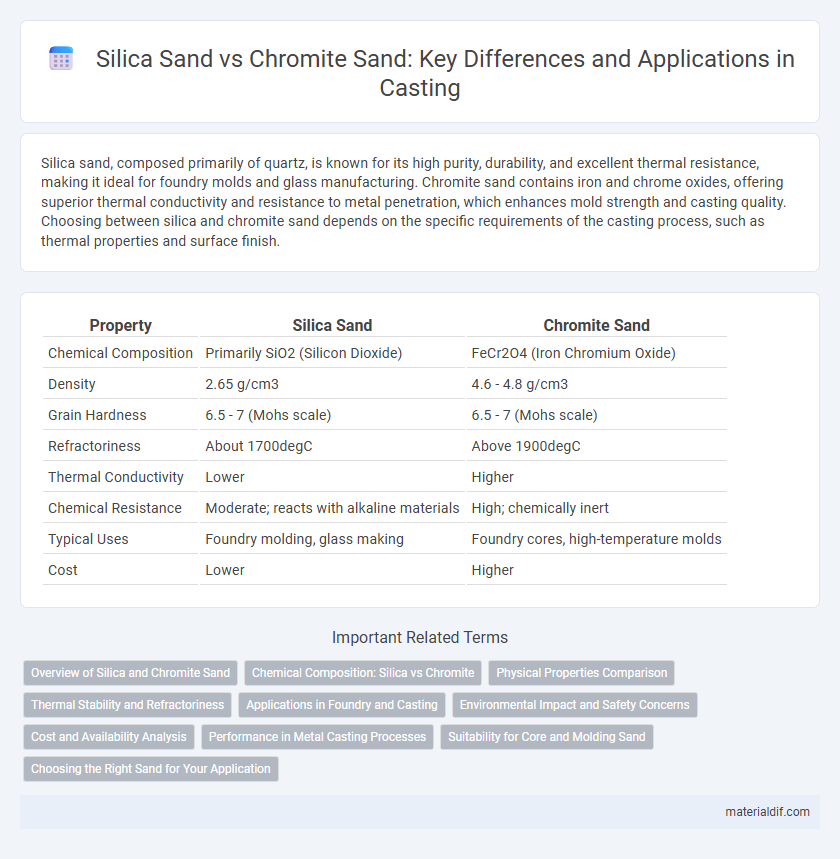

Table of Comparison

| Property | Silica Sand | Chromite Sand |

|---|---|---|

| Chemical Composition | Primarily SiO2 (Silicon Dioxide) | FeCr2O4 (Iron Chromium Oxide) |

| Density | 2.65 g/cm3 | 4.6 - 4.8 g/cm3 |

| Grain Hardness | 6.5 - 7 (Mohs scale) | 6.5 - 7 (Mohs scale) |

| Refractoriness | About 1700degC | Above 1900degC |

| Thermal Conductivity | Lower | Higher |

| Chemical Resistance | Moderate; reacts with alkaline materials | High; chemically inert |

| Typical Uses | Foundry molding, glass making | Foundry cores, high-temperature molds |

| Cost | Lower | Higher |

Overview of Silica and Chromite Sand

Silica sand, composed primarily of quartz (SiO2), is widely used in foundry and industrial applications due to its high melting point, chemical inertness, and durability. Chromite sand, containing iron chromium oxide (FeCr2O4), offers superior thermal conductivity and resistance to thermal shock, making it ideal for casting metals with high melting temperatures. Both sands serve critical roles in metal casting, with silica sand favored for its availability and cost-efficiency, while chromite sand is preferred for superior performance in high-temperature environments.

Chemical Composition: Silica vs Chromite

Silica sand primarily consists of silicon dioxide (SiO2), which provides high thermal stability and excellent refractoriness for various industrial applications. Chromite sand contains a significant amount of iron chromium oxide (FeCr2O4), offering superior wear resistance and thermal conductivity compared to silica. The distinct chemical compositions of silica and chromite sands influence their suitability for foundry molds, with silica favoring heat resistance and chromite excelling in durability and chemical inertness.

Physical Properties Comparison

Silica sand features a high silica content with a Mohs hardness of 7 and a specific gravity of 2.65, making it durable and ideal for foundry molds; its angular grains improve compactability. Chromite sand, distinguished by a higher specific gravity around 4.8 and slightly lower hardness near 6, provides excellent thermal stability and resistance to metal penetration in casting processes. The magnetic properties of chromite sand also facilitate effective recovery and reuse, contrasting with the non-magnetic nature of silica sand.

Thermal Stability and Refractoriness

Silica sand exhibits high thermal stability with a refractoriness around 1700degC, making it suitable for general foundry applications but prone to thermal expansion and occasional cracking. Chromite sand offers superior refractoriness above 1800degC and exceptional thermal stability due to its inherent resistance to thermal shock, enhancing mold durability in high-temperature casting processes. The higher refractoriness and thermal stability of chromite sand reduce defects from thermal degradation, making it preferred for steel casting where extreme heat resistance is critical.

Applications in Foundry and Casting

Silica sand is widely used in foundry applications due to its high thermal stability, refractoriness above 1700degC, and strong binding properties, making it ideal for mold and core production in metal casting processes like iron, steel, and non-ferrous metals. Chromite sand, with a higher thermal conductivity and superior resistance to thermal shock and chemical attack, is preferred for applications involving casting of superalloys and high-temperature alloys, improving mold life and surface finish in precision casting. The choice between silica and chromite sand significantly affects casting quality, mold durability, and production efficiency in foundry operations.

Environmental Impact and Safety Concerns

Silica sand poses significant health risks due to its fine crystalline silica particles, which can cause silicosis and other respiratory diseases upon prolonged inhalation, leading to stricter regulatory controls in many countries. Chromite sand, often used as a refractory material, contains heavy metals like chromium that can leach into the environment, raising concerns about soil and water contamination. Both sands require careful handling and disposal to mitigate their environmental impact and protect worker safety, emphasizing the need for effective dust control and proper waste management practices.

Cost and Availability Analysis

Silica sand is widely available and generally more cost-effective due to its abundance and extensive mining infrastructure, making it a preferred choice in many industrial applications. Chromite sand, although more expensive because of its limited deposits and specialized mining processes, offers superior thermal conductivity and resistance to metal penetration, justifying its higher cost in specific foundry uses. Cost-efficiency and supply stability often drive the selection between silica and chromite sand, with silica favored for bulk use and chromite reserved for high-performance molding needs.

Performance in Metal Casting Processes

Silica sand exhibits high refractoriness and thermal stability, making it ideal for metal casting molds requiring resistance to high temperatures. Chromite sand offers superior thermal conductivity and collapsibility, reducing cooling time and minimizing defects in castings. The choice between silica and chromite sand impacts casting surface finish, dimensional accuracy, and overall process efficiency.

Suitability for Core and Molding Sand

Silica sand, composed primarily of silicon dioxide, is widely preferred for core and molding sand due to its high refractoriness and thermal stability, enabling it to withstand elevated temperatures during metal casting processes. Chromite sand, containing chromium, offers superior thermal conductivity and chemical resistance, reducing defects like burn-on and veining in steel castings, making it particularly suitable for investment casting and high-temperature alloys. The choice between silica and chromite sand depends on the casting application, with silica favored for cost-efficiency and chromite preferred for enhanced mold life and surface finish quality.

Choosing the Right Sand for Your Application

Silica sand offers high purity and excellent chemical stability, making it ideal for glassmaking and hydraulic fracturing, whereas chromite sand provides superior thermal conductivity and abrasion resistance, preferred in foundry applications and metal casting. Selecting the right sand depends on the specific requirements such as thermal properties, chemical composition, and hardness to ensure optimal performance and durability. Cost-effectiveness and environmental impact are also critical factors when choosing between silica and chromite sand for industrial use.

Silica vs Chromite sand Infographic

materialdif.com

materialdif.com