Paver sand is specifically designed for filling joints between paving stones, offering excellent compaction and stability to prevent shifting and weed growth, while blasting sand is a coarse, high-purity sand primarily used for abrasive blasting to clean or etch surfaces. Paver sand typically has a finer texture and is more angular to lock tightly in place, whereas blasting sand is more uniform and durable to withstand abrasive forces. Choosing the right sand depends on the application: use paver sand for landscaping and patios, and blasting sand for industrial cleaning tasks.

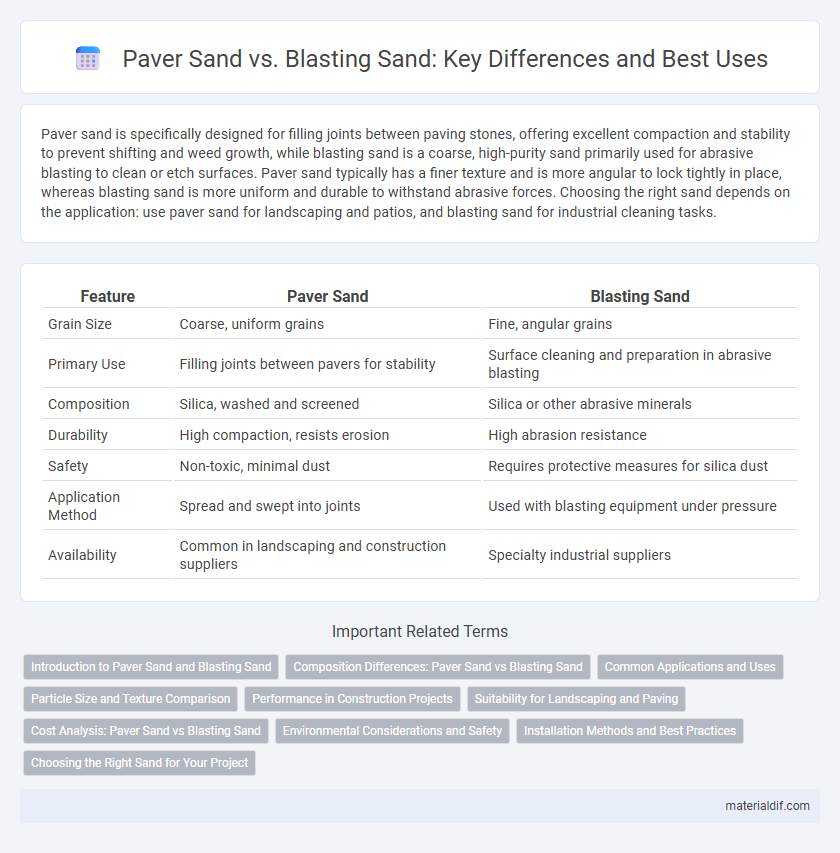

Table of Comparison

| Feature | Paver Sand | Blasting Sand |

|---|---|---|

| Grain Size | Coarse, uniform grains | Fine, angular grains |

| Primary Use | Filling joints between pavers for stability | Surface cleaning and preparation in abrasive blasting |

| Composition | Silica, washed and screened | Silica or other abrasive minerals |

| Durability | High compaction, resists erosion | High abrasion resistance |

| Safety | Non-toxic, minimal dust | Requires protective measures for silica dust |

| Application Method | Spread and swept into joints | Used with blasting equipment under pressure |

| Availability | Common in landscaping and construction suppliers | Specialty industrial suppliers |

Introduction to Paver Sand and Blasting Sand

Paver sand, also known as jointing sand, is a fine, well-graded sand specifically designed for filling gaps between pavers to create a stable and durable surface. Blasting sand, on the other hand, consists of coarse, angular grains used primarily for abrasive blasting to clean or texture surfaces in industrial applications. Both types of sand serve distinct purposes based on their particle size and composition, with paver sand enhancing outdoor hardscape installations and blasting sand providing effective surface preparation.

Composition Differences: Paver Sand vs Blasting Sand

Paver sand primarily consists of finely crushed quartz and silica particles designed to create a stable base while allowing for water permeability in outdoor paving applications. Blasting sand contains coarser and more angular grains often composed of silica or other abrasive minerals, tailored for high-impact surface cleaning and material removal. The composition differences influence their specific physical properties, including grain size, hardness, and abrasiveness, determining suitability for construction versus industrial blasting uses.

Common Applications and Uses

Paver sand is commonly used for stabilizing and filling joints between paving stones, providing a firm base for driveways, patios, and walkways. Blasting sand, characterized by its angular grains and abrasive quality, is primarily utilized in sandblasting applications to clean or etch surfaces in industrial and construction settings. Both types serve distinct roles, with paver sand enhancing structural integrity and blasting sand delivering surface preparation and finishing.

Particle Size and Texture Comparison

Paver sand typically features medium-fine, angular particles ranging from 0.1 to 0.5 millimeters that provide excellent compaction and stability for interlocking pavers. In contrast, blasting sand has coarser, more uniform grains, generally between 0.2 to 1 millimeter, with a rough, gritty texture designed for abrasive cleaning and finishing surfaces. The finer, angular texture of paver sand enhances locking strength, while the coarser texture of blasting sand offers superior abrasive properties.

Performance in Construction Projects

Paver sand, composed of coarse-grained silica, offers excellent compaction and stability, making it ideal for laying pavers and preventing shifting in walkways and driveways. Blasting sand, characterized by its fine grains and high silica content, is engineered for abrasive performance rather than load-bearing capacity, limiting its effectiveness in structural base layers. For superior construction performance, paver sand ensures durability and even weight distribution, while blasting sand serves more specialized roles in surface preparation and cleaning.

Suitability for Landscaping and Paving

Paver sand, also known as jointing sand, is specifically designed for landscaping and paving projects, providing excellent stability and drainage between pavers due to its fine, rounded grains. Blasting sand, with its coarser, angular texture, is primarily intended for abrasive cleaning and is less suitable for locking paving stones or supporting plant growth. Choosing paver sand ensures long-lasting, even surfaces ideal for patios and walkways, while blasting sand lacks the physical properties needed for durable landscaping applications.

Cost Analysis: Paver Sand vs Blasting Sand

Paver sand typically costs between $20 to $40 per ton, making it a budget-friendly option for landscaping and patio projects, whereas blasting sand ranges from $50 to $100 per ton due to its specialized industrial use and higher purity standards. The price difference reflects the distinct granule sizes and silica content required for blasting sand, which must meet stricter safety and performance regulations. Choosing between paver sand and blasting sand hinges on project requirements and cost-effectiveness, with paver sand suited for aggregate bedding and blasting sand preferred for abrasive applications.

Environmental Considerations and Safety

Paver sand, typically composed of crushed stone and finer particles, is favored in landscaping for its stability and lower dust emissions, reducing environmental impact and respiratory risks. Blasting sand, often consisting of sharp silica particles, poses higher health hazards due to silica dust inhalation, necessitating stringent safety measures and protective equipment during use. Choosing paver sand over blasting sand supports safer handling practices and minimizes harmful airborne particulates that contribute to environmental pollution and worker health issues.

Installation Methods and Best Practices

Paver sand is specifically engineered for use in the installation of paving stones, featuring angular grains that lock tightly together and promote drainage, making it ideal for filling joints and leveling base layers. Blasting sand, typically composed of finer, rounder particles, is unsuitable for paver installation due to poor compaction and stability, and is better reserved for abrasive cleaning applications. Best practices for installing paver sand include spreading a consistent layer, compacting with a plate compactor, and ensuring joints are fully filled to prevent shifting and weed growth.

Choosing the Right Sand for Your Project

Paver sand, also known as joint sand, is specifically graded to fill gaps between pavers and enhance stability by locking them in place. Blasting sand, typically finer and more abrasive, is designed for industrial applications such as surface cleaning rather than construction. Selecting the appropriate sand depends on the project's purpose: paver sand for landscaping and hardscaping, blasting sand for abrasive cleaning tasks.

Paver Sand vs Blasting Sand Infographic

materialdif.com

materialdif.com