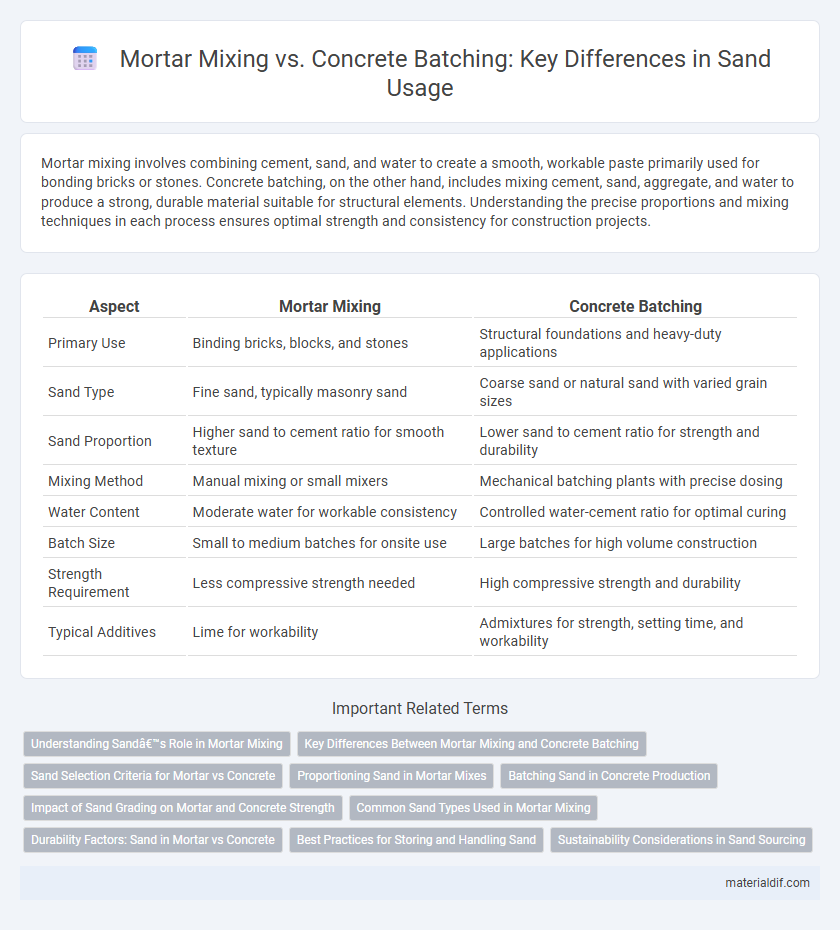

Mortar mixing involves combining cement, sand, and water to create a smooth, workable paste primarily used for bonding bricks or stones. Concrete batching, on the other hand, includes mixing cement, sand, aggregate, and water to produce a strong, durable material suitable for structural elements. Understanding the precise proportions and mixing techniques in each process ensures optimal strength and consistency for construction projects.

Table of Comparison

| Aspect | Mortar Mixing | Concrete Batching |

|---|---|---|

| Primary Use | Binding bricks, blocks, and stones | Structural foundations and heavy-duty applications |

| Sand Type | Fine sand, typically masonry sand | Coarse sand or natural sand with varied grain sizes |

| Sand Proportion | Higher sand to cement ratio for smooth texture | Lower sand to cement ratio for strength and durability |

| Mixing Method | Manual mixing or small mixers | Mechanical batching plants with precise dosing |

| Water Content | Moderate water for workable consistency | Controlled water-cement ratio for optimal curing |

| Batch Size | Small to medium batches for onsite use | Large batches for high volume construction |

| Strength Requirement | Less compressive strength needed | High compressive strength and durability |

| Typical Additives | Lime for workability | Admixtures for strength, setting time, and workability |

Understanding Sand’s Role in Mortar Mixing

Sand in mortar mixing acts as a key aggregate that provides bulk, strength, and volume, ensuring proper adhesion and workability in masonry applications. Its particle size and cleanliness directly influence the mortar's consistency and durability, affecting the bond between bricks or stones and the cement paste. Understanding the role of sand in mortar mixing helps optimize the ratio of sand to cement, enhancing the structural integrity and lifespan of masonry structures.

Key Differences Between Mortar Mixing and Concrete Batching

Mortar mixing involves combining sand, cement, and water to create a workable paste primarily used for bonding bricks or stones, while concrete batching mixes sand, cement, water, and aggregate to form a sturdy material for structural elements. Mortar typically has a finer sand grain size and higher water content for workability, whereas concrete batching requires precise aggregate proportions and less water to achieve compressive strength. The key distinction lies in the composition and purpose: mortar is adhesive and smooth, whereas concrete is robust and load-bearing.

Sand Selection Criteria for Mortar vs Concrete

Sand selection for mortar prioritizes fine, clean, and well-graded particles to ensure smooth workability and strong adhesion with cement and lime, crucial for masonry strength. Concrete batching requires coarser sand with a broader particle size distribution to enhance aggregate interlocking, reducing voids and improving overall structural integrity. In both applications, sand must be free from impurities like clay, silt, and organic matter to prevent weakening of the mix and ensure optimal hydration and bonding.

Proportioning Sand in Mortar Mixes

Proportioning sand in mortar mixes critically affects the workability, strength, and durability of the final product, with typical mortar mixes containing a sand-to-cement ratio ranging from 4:1 to 6:1. Unlike concrete batching, where sand is balanced with coarse aggregates and precise water-cement ratios for structural loads, mortar requires finer, well-graded sand to ensure smooth application and bonding in masonry joints. Uniform sand grading and proper moisture content in mortar mixes optimize bonding characteristics and reduce shrinkage cracks compared to the coarser, varied aggregates used in concrete batching.

Batching Sand in Concrete Production

Batching sand in concrete production involves precise measurement and proportioning of sand to ensure consistent concrete quality and strength. Mortar mixing typically uses sand with finer granules and different ratios compared to concrete batching, which requires a balanced mix of sand, cement, and aggregates for structural integrity. Accurate sand batching reduces variability in concrete performance, enhancing durability and workability in construction projects.

Impact of Sand Grading on Mortar and Concrete Strength

Sand grading significantly influences the strength and durability of both mortar and concrete by affecting particle packing density and void content; well-graded sand ensures a denser mixture, reducing water demand and enhancing compressive strength. In mortar mixing, fine sand with a consistent grading improves workability and bond strength between masonry units, while in concrete batching, a balanced distribution of sand particle sizes contributes to optimal aggregate interlock and load transfer. Poorly graded sand leads to weak mortar joints and brittle concrete, increasing susceptibility to cracking and reducing overall structural integrity.

Common Sand Types Used in Mortar Mixing

Mortar mixing commonly utilizes sharp sand, also known as coarse sand, favored for its angular grains that enhance bonding strength in masonry work. River sand, with its smooth texture and finer particles, is another preferred type, providing a softer finish suitable for plastering. Blended sand, a mix of sharp and fine sands, balances workability and durability, optimizing mortar performance in various construction applications.

Durability Factors: Sand in Mortar vs Concrete

Sand in mortar typically features finer grains that enhance workability and adhesion, crucial for improving the durability of masonry joints by reducing cracking and weathering. In concrete batching, coarser sand contributes to a robust aggregate matrix that resists compressive stress and erosion, significantly affecting the structural integrity and longevity of the concrete. The mineral composition and cleanliness of sand directly influence the bonding strength and permeability, making its selection vital for optimizing durability in both mortar and concrete applications.

Best Practices for Storing and Handling Sand

Store sand in clean, dry, and well-ventilated areas to prevent contamination and moisture absorption that can weaken mortar or concrete mixes. Use covered storage bins or silos to protect sand from environmental exposure and segregate by particle size for precise batching. Implement regular quality checks for sand grading and cleanliness to ensure optimal bonding strength in mortar and concrete applications.

Sustainability Considerations in Sand Sourcing

Mortar mixing primarily uses fine sand and requires smaller quantities, allowing for more localized and sustainable sand sourcing that minimizes environmental degradation. Concrete batching demands larger volumes of diverse aggregates, increasing the need for sustainable extraction practices to reduce habitat disruption and resource depletion. Sustainable sand sourcing in both processes involves selecting suppliers with certifications for responsible mining and implementing strategies like sand recycling and alternative materials to lower ecological impact.

Mortar mixing vs Concrete batching Infographic

materialdif.com

materialdif.com