Play sand is specifically processed and cleaned to ensure it is non-toxic, safe for children, and free of impurities, making it suitable for playgrounds and sandboxes. Industrial sand, also known as silica sand, is primarily used in manufacturing processes such as glassmaking, foundry molds, and hydraulic fracturing due to its high quartz content and specific grain size. The key difference lies in their intended applications and purity levels, with play sand prioritizing safety and cleanliness, while industrial sand emphasizes technical specifications and mineral composition.

Table of Comparison

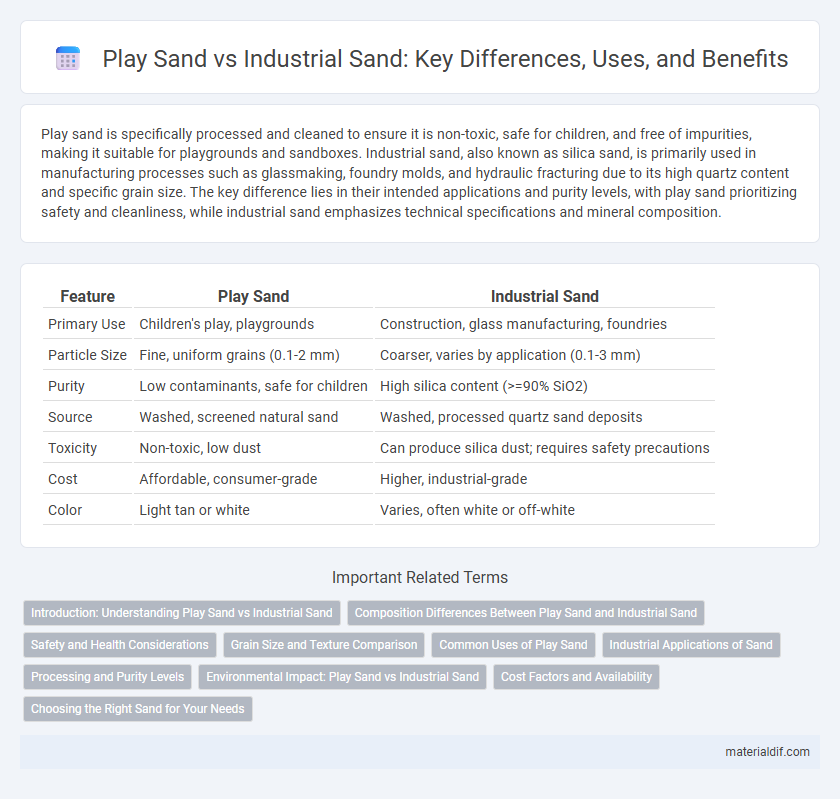

| Feature | Play Sand | Industrial Sand |

|---|---|---|

| Primary Use | Children's play, playgrounds | Construction, glass manufacturing, foundries |

| Particle Size | Fine, uniform grains (0.1-2 mm) | Coarser, varies by application (0.1-3 mm) |

| Purity | Low contaminants, safe for children | High silica content (>=90% SiO2) |

| Source | Washed, screened natural sand | Washed, processed quartz sand deposits |

| Toxicity | Non-toxic, low dust | Can produce silica dust; requires safety precautions |

| Cost | Affordable, consumer-grade | Higher, industrial-grade |

| Color | Light tan or white | Varies, often white or off-white |

Introduction: Understanding Play Sand vs Industrial Sand

Play sand is specifically processed for safety and cleanliness, making it ideal for children's recreational use in playgrounds and sandboxes. Industrial sand, also known as silica sand, is mined for its high-purity quartz content and used in manufacturing, construction, and hydraulic fracturing. The primary distinction lies in particle size, composition, and intended application, with play sand emphasizing non-toxicity and uniform texture, while industrial sand focuses on chemical and physical properties suitable for technical processes.

Composition Differences Between Play Sand and Industrial Sand

Play sand primarily consists of fine, clean silica particles, usually quartz, with minimal impurities to ensure safety and non-toxicity for children's use. Industrial sand, also known as frac sand or silica sand, contains higher purity levels of quartz with specific grain size, shape, and strength tailored for applications like hydraulic fracturing, glass manufacturing, and foundry casting. The differences in mineral composition, grain angularity, and contaminant content distinguish play sand's safety compliance from industrial sand's performance specifications.

Safety and Health Considerations

Play sand is specifically processed to be free of harmful contaminants, making it non-toxic and safe for children's use in playgrounds and sandboxes. Industrial sand often contains silica dust, which poses serious health risks like silicosis and lung cancer when inhaled without proper protective equipment. Proper ventilation, respiratory protection, and adherence to OSHA regulations are critical when handling industrial sand to minimize exposure to hazardous airborne particles.

Grain Size and Texture Comparison

Play sand features fine, uniform grains typically sized between 0.25 to 0.5 millimeters, providing a soft, smooth texture ideal for safe children's play areas. Industrial sand, often coarser with grain sizes ranging from 0.5 to 2 millimeters, exhibits a rougher texture suitable for construction, glass-making, and hydraulic fracturing. The grain size and texture differences directly influence the sand's suitability, with play sand prioritizing comfort and cleanliness, while industrial sand emphasizes durability and structural properties.

Common Uses of Play Sand

Play sand is primarily used in recreational settings such as children's sandboxes, playgrounds, and sensory play areas due to its fine texture and non-toxic properties. It is also popular for crafting activities and therapeutic applications, promoting tactile development and creativity in kids. Unlike industrial sand, which is utilized in construction and manufacturing, play sand prioritizes safety and cleanliness for direct human contact.

Industrial Applications of Sand

Industrial sand, also known as silica sand, is integral to manufacturing processes in industries such as glass production, foundry casting, and hydraulic fracturing. Its high purity and consistent grain size make it ideal for producing fiberglass, molds, and proppants that enhance oil and gas extraction. Unlike play sand, which is primarily used for recreational purposes, industrial sand undergoes rigorous processing to meet specifications required for these critical applications.

Processing and Purity Levels

Play sand undergoes minimal processing to ensure it is clean, fine-grained, and free from harmful materials, making it safe for children's use. Industrial sand, also known as frac sand or silica sand, is processed extensively to achieve high purity levels of silicon dioxide (SiO2), often exceeding 99%, essential for applications like glass manufacturing and hydraulic fracturing. The purity of industrial sand involves advanced washing, acid treatment, and sieving techniques, whereas play sand prioritizes safety standards over chemical refinement.

Environmental Impact: Play Sand vs Industrial Sand

Play sand is typically sourced from cleaner, less disturbed environments, resulting in minimal environmental contamination and safer usage for children and recreational areas. Industrial sand extraction often involves large-scale mining operations that can disrupt ecosystems, cause habitat loss, and generate significant dust and pollution. Regulatory measures and reclamation efforts are critical in mitigating the environmental impact of industrial sand activities compared to the relatively low-impact nature of play sand production.

Cost Factors and Availability

Play sand typically costs more due to its higher purity, safety standards, and finer grain size, making it suitable for children's use and recreational areas. Industrial sand, often used in construction and manufacturing, is more abundant and cheaper because it requires less processing and quality control. Availability of play sand is limited to specialty suppliers, whereas industrial sand is widely accessible from numerous quarries and bulk distributors.

Choosing the Right Sand for Your Needs

Play sand is specifically processed to be clean, safe, and free of harmful contaminants, making it ideal for children's sandboxes and recreational use. Industrial sand, also known as frac sand or silica sand, is characterized by its high purity and consistent grain size, suitable for construction, glass manufacturing, and hydraulic fracturing. Selecting the right sand depends on the application requirements, such as safety standards for play areas or specific chemical and physical properties for industrial processes.

Play sand vs Industrial sand Infographic

materialdif.com

materialdif.com