Rounded sand particles have smooth, curved edges resulting from prolonged weathering and transportation, which enhances their flowability and reduces compaction in construction applications. Angular sand grains possess sharp edges and rough surfaces, providing better interlocking and higher shear strength, making them ideal for concrete and asphalt mixes. The choice between rounded and angular sand significantly impacts the stability and workability of building materials.

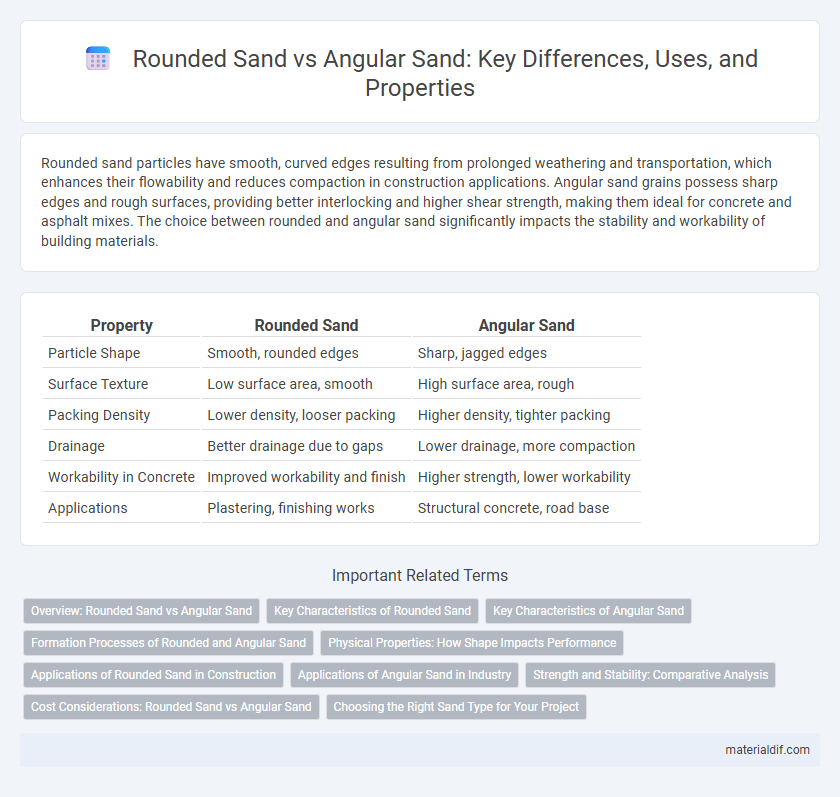

Table of Comparison

| Property | Rounded Sand | Angular Sand |

|---|---|---|

| Particle Shape | Smooth, rounded edges | Sharp, jagged edges |

| Surface Texture | Low surface area, smooth | High surface area, rough |

| Packing Density | Lower density, looser packing | Higher density, tighter packing |

| Drainage | Better drainage due to gaps | Lower drainage, more compaction |

| Workability in Concrete | Improved workability and finish | Higher strength, lower workability |

| Applications | Plastering, finishing works | Structural concrete, road base |

Overview: Rounded Sand vs Angular Sand

Rounded sand grains exhibit smooth, curved surfaces due to prolonged abrasion during transport, resulting in better workability and compaction in concrete mixtures. Angular sand grains have sharp edges and rough surfaces, providing superior interlocking and bonding strength, ideal for high-strength construction applications. Understanding the morphological differences between rounded and angular sand helps optimize material selection for specific engineering requirements.

Key Characteristics of Rounded Sand

Rounded sand grains exhibit smooth, curved edges and a more uniform shape resulting from extensive weathering and transportation by wind or water. This characteristic enhances their flowability and reduces interlocking, making them ideal for concrete mixes requiring workability and durability. Rounded sand also tends to have lower surface area than angular sand, influencing water demand and bonding in construction applications.

Key Characteristics of Angular Sand

Angular sand features sharp, jagged edges and irregular particle shapes, resulting from minimal weathering and mechanical breakdown. Its high surface area enhances cohesion and bonding in construction materials, improving strength and durability in concrete mixes. Angular sand's rough texture promotes better interlock and stability in drainage systems and asphalt pavements.

Formation Processes of Rounded and Angular Sand

Rounded sand grains form primarily through prolonged abrasion and transportation by water or wind, which smooths their edges over time. In contrast, angular sand grains originate from mechanical weathering and fracture of parent rock, retaining sharp edges due to minimal transport or exposure. These distinct formation processes influence sediment texture and behavior in construction and geological applications.

Physical Properties: How Shape Impacts Performance

Rounded sand grains exhibit lower surface area and reduced interlocking ability compared to angular sand, resulting in higher flowability and compaction efficiency. Angular sand's irregular shapes increase surface friction and bonding strength, enhancing load-bearing capacity and shear resistance in concrete and asphalt mixtures. The choice between rounded and angular sand shapes directly influences material durability, permeability, and mechanical performance in construction applications.

Applications of Rounded Sand in Construction

Rounded sand, characterized by its smooth, well-worn grains, is widely used in concrete and mortar applications due to its excellent workability and ease of compaction. Its uniform shape improves flowability in concrete mixes, enhancing pumpability for large-scale construction projects such as high-rise buildings and bridges. Rounded sand also promotes better finish quality in plastering and rendering by reducing voids and improving surface smoothness.

Applications of Angular Sand in Industry

Angular sand's sharp edges and irregular shapes enhance its bonding properties, making it ideal for concrete production and construction applications. This type of sand improves strength and stability in asphalt mixtures, masonry work, and road base materials. Industries rely on angular sand for filtration systems and refractory products due to its durability and resistance to heat.

Strength and Stability: Comparative Analysis

Rounded sand grains exhibit lower interlocking capabilities due to their smooth surfaces, resulting in reduced shear strength and stability in construction applications. Angular sand, characterized by sharp edges and irregular shapes, enhances mechanical interlock and friction, providing superior strength and stability in concrete and soil stabilization. Studies indicate angular sand improves load-bearing capacity by up to 15%, making it preferable for high-strength structural projects.

Cost Considerations: Rounded Sand vs Angular Sand

Rounded sand generally incurs higher transportation and processing costs due to its natural weathering and sorting, which makes it desirable for specific construction applications such as concrete and masonry where workability is important. Angular sand, sourced often from crushed rock, tends to be less expensive but may increase labor costs due to its rough texture requiring more effort for compaction and finishing. Cost considerations between rounded and angular sand ultimately depend on the balance between material price, handling expenses, and project-specific performance requirements.

Choosing the Right Sand Type for Your Project

Rounded sand, characterized by its smooth, rounded grains, offers superior workability and ease of compaction, making it ideal for concrete mixes requiring high flowability and decorative finishes. Angular sand, with its jagged, irregular particles, provides better mechanical interlocking and higher strength, which is essential for structural projects demanding increased load-bearing capacity. Selecting the right sand type depends on the project's specific requirements for strength, finish, and durability, ensuring optimal performance and longevity.

Rounded sand vs Angular sand Infographic

materialdif.com

materialdif.com