Dune sand is typically finer and more uniform in grain size compared to sea sand, which often contains shell fragments and salt impurities. The low salt content and well-sorted grains of dune sand make it preferable for construction and concrete production. Sea sand requires thorough washing to remove salt and organic materials before use to prevent corrosion and structural damage.

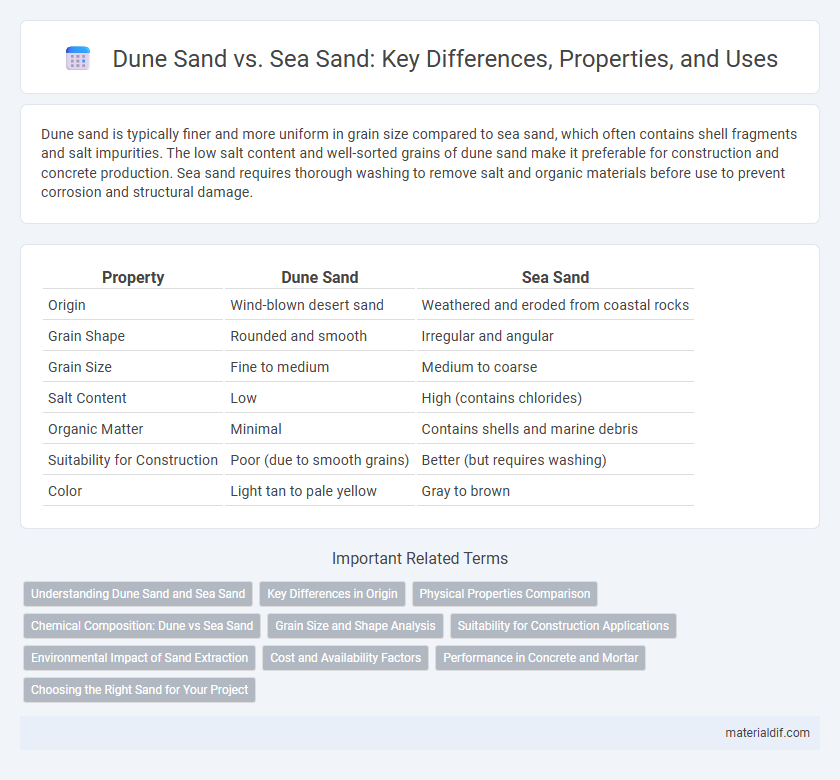

Table of Comparison

| Property | Dune Sand | Sea Sand |

|---|---|---|

| Origin | Wind-blown desert sand | Weathered and eroded from coastal rocks |

| Grain Shape | Rounded and smooth | Irregular and angular |

| Grain Size | Fine to medium | Medium to coarse |

| Salt Content | Low | High (contains chlorides) |

| Organic Matter | Minimal | Contains shells and marine debris |

| Suitability for Construction | Poor (due to smooth grains) | Better (but requires washing) |

| Color | Light tan to pale yellow | Gray to brown |

Understanding Dune Sand and Sea Sand

Dune sand primarily consists of fine, well-sorted quartz grains shaped by wind erosion, resulting in smooth, rounded particles ideal for certain construction and landscaping applications. Sea sand is often coarser and contains a mix of shell fragments, salt, and organic materials, which can affect its suitability for concrete and require thorough washing to prevent corrosion. Understanding these differences in grain size, composition, and cleanliness is essential for selecting the appropriate sand type in industrial and environmental contexts.

Key Differences in Origin

Dune sand originates from wind-blown particles primarily composed of quartz and feldspar, formed in desert environments with fine, rounded grains shaped by aeolian processes. Sea sand is derived from the mechanical weathering of rocks and shells in marine settings, containing a mix of minerals and organic matter with coarser, more angular grains due to wave and tidal action. The origin differences influence sand grain size, composition, and cohesiveness, impacting their suitability for construction and ecological functions.

Physical Properties Comparison

Dune sand features well-rounded, fine grains with high quartz content, resulting in excellent drainage and low cohesion, while sea sand consists of coarser, angular grains with shell fragments and higher salt content, impacting its durability. The particle size distribution of dune sand tends to be more uniform, promoting better compaction and stability compared to the heterogeneous composition of sea sand. Differences in mineral composition and grain shape influence the suitability of each sand type for construction and landscaping applications.

Chemical Composition: Dune vs Sea Sand

Dune sand primarily consists of quartz and feldspar with minimal salt content, making it chemically stable and low in chloride ions compared to sea sand. Sea sand contains significant amounts of sodium chloride and other soluble salts, including magnesium and sulfate compounds, which can accelerate corrosion in concrete structures. The high salt concentration in sea sand necessitates thorough washing to reduce chemical impurities for construction uses, whereas dune sand requires less processing due to its lower salinity and chemical inertness.

Grain Size and Shape Analysis

Dune sand typically features well-sorted, fine to medium grain sizes with mostly rounded and smooth grains due to prolonged wind transportation, enhancing its uniformity and porosity. Sea sand exhibits coarser and more angular grains, influenced by shorter distances of transport and wave action, often containing shell fragments and other marine deposits. Grain size and shape analysis of these sands is crucial for determining their suitability in construction, filtration, and soil stabilization applications.

Suitability for Construction Applications

Dune sand, characterized by its fine grain size and rounded particles, often lacks the angularity required for strong bonding in concrete, making it less suitable for structural construction. Sea sand contains salt and organic impurities, which necessitate thorough washing to prevent corrosion of reinforcement and ensure durability in construction projects. For optimal construction applications, pit or river sand with angular particles and minimal contaminants is preferred over both dune and untreated sea sand.

Environmental Impact of Sand Extraction

Dune sand extraction disrupts fragile desert ecosystems, leading to habitat loss, soil erosion, and reduced biodiversity, whereas sea sand mining primarily causes coastal erosion, marine habitat destruction, and water quality degradation. The extraction of dune sand often results in long-term land degradation and desertification, while sea sand removal can accelerate shoreline retreat and negatively impact fish breeding grounds. Sustainable management practices are essential to minimize the environmental consequences associated with both dune and sea sand extraction.

Cost and Availability Factors

Dune sand is generally more expensive than sea sand due to the higher costs associated with extraction and processing from desert areas. Sea sand is more readily available and often cheaper because it is abundant along coastlines and requires less intensive processing. However, the availability of sea sand can be limited by environmental regulations to prevent coastal erosion and habitat damage.

Performance in Concrete and Mortar

Dune sand, characterized by its rounded grains and high silica content, often results in lower concrete and mortar strength due to poor particle interlock and reduced bonding surface. Sea sand contains salt and impurities that can cause corrosion in reinforced concrete, yet its angular grains typically provide better mechanical performance than dune sand. Proper washing and treatment of sea sand enhance its suitability for construction, whereas dune sand generally requires blending with crushed sand to improve durability and structural integrity.

Choosing the Right Sand for Your Project

Dune sand, characterized by its fine, rounded grains and low cohesion, is ideal for landscaping and decorative purposes but generally unsuitable for construction due to poor compaction and binding properties. Sea sand contains higher salt content and angular grains, requiring thorough washing before use in concrete to prevent corrosion and structural weakness. Selecting the right sand involves assessing project requirements such as strength, durability, and environmental exposure to ensure optimal performance.

Dune Sand vs Sea Sand Infographic

materialdif.com

materialdif.com