Mason sand features finer, smoother grains ideal for mixing mortar, offering better workability and a clean finish in bricklaying projects. Concrete sand contains coarser particles designed to provide strength and durability in concrete mixes, ensuring proper compaction and load-bearing capacity. Choosing the correct sand type enhances the structural integrity and appearance of masonry and concrete structures.

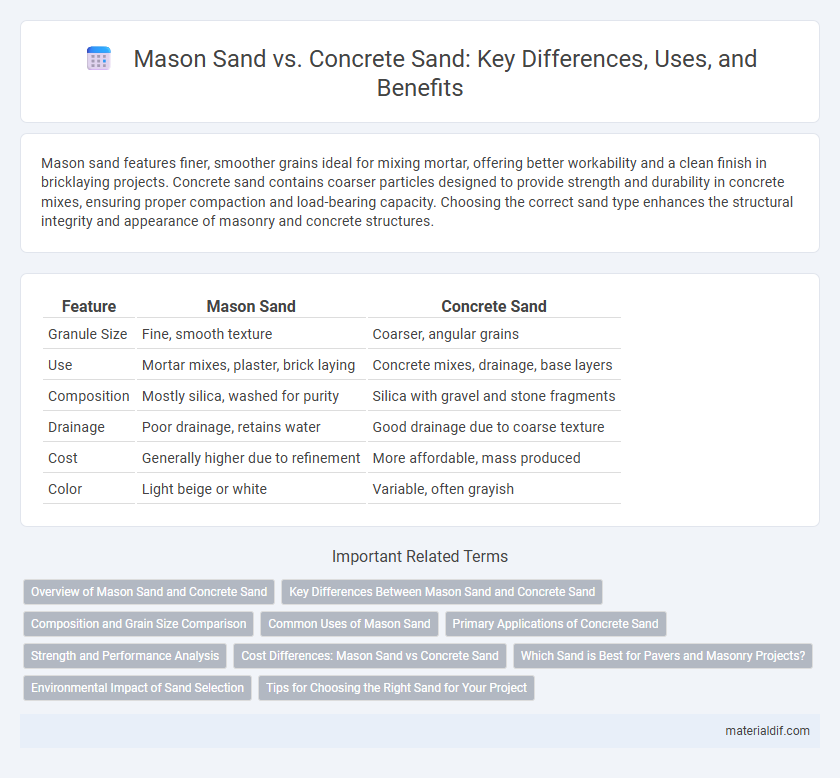

Table of Comparison

| Feature | Mason Sand | Concrete Sand |

|---|---|---|

| Granule Size | Fine, smooth texture | Coarser, angular grains |

| Use | Mortar mixes, plaster, brick laying | Concrete mixes, drainage, base layers |

| Composition | Mostly silica, washed for purity | Silica with gravel and stone fragments |

| Drainage | Poor drainage, retains water | Good drainage due to coarse texture |

| Cost | Generally higher due to refinement | More affordable, mass produced |

| Color | Light beige or white | Variable, often grayish |

Overview of Mason Sand and Concrete Sand

Mason sand is a fine-grained, smooth sand used primarily for masonry and plastering projects, providing a clean finish and better adhesion for mortar. Concrete sand contains coarser grains and is designed for use in concrete mixes to improve strength and drainage. Both sands vary in texture and size, impacting their suitability for specific construction applications.

Key Differences Between Mason Sand and Concrete Sand

Mason sand features fine, rounded grains ideal for plastering and finishing masonry work, while concrete sand consists of coarser, angular particles designed to provide structural strength in concrete mixes. The finer texture of mason sand enables smooth surfaces and better mortar bonding, whereas the durability and drainage properties of concrete sand support strong, long-lasting concrete slabs and foundations. Choosing the appropriate sand depends on the specific construction application, with mason sand best for detailed masonry and concrete sand suited for foundational and structural purposes.

Composition and Grain Size Comparison

Mason sand consists primarily of fine, smooth grains of quartz and silica, typically ranging from 0.1 to 0.5 millimeters, designed for ease of manipulation and aesthetic finishes in bricklaying and plastering. Concrete sand has coarser grains, generally between 0.5 and 2 millimeters, composed of crushed rock fragments and quartz that provide strength and optimal binding properties in concrete mixes. The finer composition of mason sand creates a denser, smoother texture, whereas the larger grain size of concrete sand ensures better structural integrity and drainage capabilities.

Common Uses of Mason Sand

Mason sand is primarily used for masonry applications such as mortar mixes for bricklaying and block work due to its fine texture and clean composition. Unlike concrete sand, which is coarser and suited for structural concrete work and drainage systems, mason sand provides better workability and bond strength in mortar joints. Its fine grains and consistent particle size make it ideal for finishing and smoothing surfaces in plastering and pointing tasks.

Primary Applications of Concrete Sand

Concrete sand is primarily used in the construction industry for mixing concrete due to its coarse texture and angular grains, which provide better bonding and strength compared to mason sand. It is essential in creating strong foundations, slabs, and driveways, ensuring durability and stability in structural applications. Unlike mason sand, which is finer and used for mortar and plaster, concrete sand's optimal grain size enhances load-bearing capacity in concrete mixtures.

Strength and Performance Analysis

Mason sand, characterized by its fine texture and uniform grain size, provides excellent workability but lower compressive strength compared to concrete sand. Concrete sand, coarser with angular particles, enhances bonding in concrete mixes, resulting in superior strength and durability for structural applications. Performance analysis indicates that concrete sand improves load-bearing capacity and resistance to cracking, making it the preferred choice for high-strength concrete formulations.

Cost Differences: Mason Sand vs Concrete Sand

Mason sand generally costs more than concrete sand due to its finer grain size and higher purity, which are essential for masonry work requiring a smooth finish. Concrete sand is coarser and more abundant, making it less expensive and suitable for mixing concrete where strength is prioritized over texture. The price difference typically reflects the specific manufacturing processes and quality standards associated with each type of sand.

Which Sand is Best for Pavers and Masonry Projects?

Mason sand has finer particles and is better suited for pavers and masonry projects because it fills gaps smoothly and provides a stable base for bricks and blocks. Concrete sand is coarser and designed for mixing with cement to create strong concrete, making it less ideal for detailed masonry work. For durable, clean joints and a neat finish in paver installations, mason sand is the preferred choice.

Environmental Impact of Sand Selection

Mason sand, typically finer and sourced from riverbeds, can lead to more habitat disruption and waterway sedimentation compared to concrete sand, which is usually coarser and extracted from quarries with more controlled environmental practices. Concrete sand's granulometry supports better drainage and reduces runoff, minimizing soil erosion and pollution risks. Choosing concrete sand over mason sand contributes to sustainable construction by lowering ecosystem disturbances and preserving biodiversity in extraction areas.

Tips for Choosing the Right Sand for Your Project

When selecting sand for your project, choose Mason sand for smooth, decorative finishes and concrete sand for structural strength and durability in mixing concrete. Consider particle size and texture; Mason sand is finer and ideal for bricklaying and plaster, while coarser concrete sand provides better bonding for concrete mixtures. Ensure compatibility with project requirements to achieve optimal adhesion and finish quality.

Mason sand vs Concrete sand Infographic

materialdif.com

materialdif.com