Resin-coated sand offers superior bonding strength and durability compared to uncoated sand, making it ideal for high-precision casting applications. Its uniform coating enhances mold stability and reduces defects, while uncoated sand lacks this consistency and often results in weaker molds. The improved surface properties of resin-coated sand lead to better dimensional accuracy and smoother finishes in metal casting.

Table of Comparison

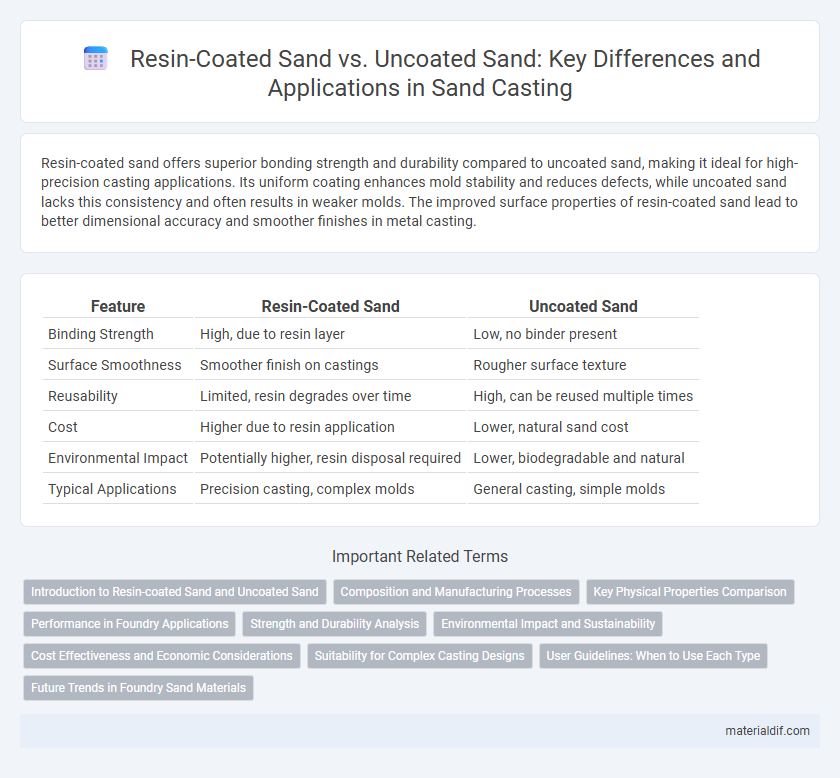

| Feature | Resin-Coated Sand | Uncoated Sand |

|---|---|---|

| Binding Strength | High, due to resin layer | Low, no binder present |

| Surface Smoothness | Smoother finish on castings | Rougher surface texture |

| Reusability | Limited, resin degrades over time | High, can be reused multiple times |

| Cost | Higher due to resin application | Lower, natural sand cost |

| Environmental Impact | Potentially higher, resin disposal required | Lower, biodegradable and natural |

| Typical Applications | Precision casting, complex molds | General casting, simple molds |

Introduction to Resin-coated Sand and Uncoated Sand

Resin-coated sand consists of natural sand grains bonded with a synthetic resin, offering enhanced strength, reduced permeability, and improved surface finish in casting processes. Uncoated sand is raw, natural sand without any binding agents, resulting in lower strength and higher tendencies for defects such as sand blow and metal penetration. The resin coating in sand improves mold stability and dimensional accuracy, making it a preferred choice for high-quality metal casting applications.

Composition and Manufacturing Processes

Resin-coated sand consists of sand grains bonded with synthetic resin binders through a polymerization curing process, resulting in enhanced strength and improved surface finish in foundry molds. Uncoated sand, primarily composed of natural silica or quartz with no resin additives, is processed through mechanical attrition and screening to achieve desired grain size and cleanliness but lacks the adhesive properties of coated sand. Manufacturing resin-coated sand involves mixing dry resin with sand followed by curing under controlled temperature, while uncoated sand requires simple washing and drying without chemical treatment.

Key Physical Properties Comparison

Resin-coated sand exhibits higher strength, improved abrasion resistance, and enhanced thermal stability compared to uncoated sand, making it ideal for foundry applications. Uncoated sand, while more cost-effective, lacks the bonding properties that resin coating provides, resulting in lower tensile strength and greater friability. The coated surface allows for better mold integrity and reduced defects in casting processes.

Performance in Foundry Applications

Resin-coated sand offers superior mold strength and better surface finish quality in foundry applications compared to uncoated sand, due to enhanced bonding properties that reduce sand erosion and improve dimensional accuracy. It exhibits higher thermal stability and improved permeability, resulting in more precise casting details and fewer defects. Uncoated sand, while economical, often leads to lower mold integrity and increased surface roughness, impacting overall casting performance negatively.

Strength and Durability Analysis

Resin-coated sand exhibits superior strength and durability compared to uncoated sand due to its enhanced bonding properties, which reduce friability and increase resilience under mechanical stress. The resin layer acts as a protective barrier, improving resistance to abrasion, moisture infiltration, and thermal deformation, thereby extending the lifespan of foundry molds and cores. Uncoated sand lacks this protective coating, resulting in weaker structural integrity and higher susceptibility to degradation during casting processes.

Environmental Impact and Sustainability

Resin-coated sand reduces the need for binders and lowers emissions during the casting process, contributing to a smaller environmental footprint compared to uncoated sand. It enables higher sand reclamation rates, minimizing waste and conserving natural silica resources, thus promoting sustainability in foundry operations. Uncoated sand, while less costly, often results in higher consumption and disposal amounts, increasing environmental degradation and reducing eco-efficiency.

Cost Effectiveness and Economic Considerations

Resin-coated sand typically incurs higher initial costs due to the resin application process but offers better reusability and reduced waste, leading to long-term cost savings in foundry operations. Uncoated sand is cheaper upfront but may result in higher disposal and replacement expenses because of its lower durability and poorer mold quality. Evaluating economic considerations, resin-coated sand often proves more cost-effective in large-scale or precision casting projects due to improved yield and reduced scrap rates.

Suitability for Complex Casting Designs

Resin-coated sand offers superior suitability for complex casting designs due to its enhanced mold strength and precision, which minimizes defects and improves dimensional accuracy. Uncoated sand lacks the binding properties of resin, resulting in weaker molds that may deform under intricate patterns or high-pressure casting. The consistent coating on resin-coated sand ensures better surface finish and detail replication, making it ideal for intricate and high-quality castings.

User Guidelines: When to Use Each Type

Resin-coated sand is ideal for applications requiring high bonding strength and excellent surface finish, such as in metal casting molds where precise shapes and smooth surfaces are crucial. Uncoated sand is suitable for simpler molding needs, cost-effective foundry processes, and situations where easy reclamation and reuse are prioritized. Users should opt for resin-coated sand when enhanced mechanical properties and dimensional accuracy are required, while uncoated sand serves well in less demanding, high-volume production environments.

Future Trends in Foundry Sand Materials

Resin-coated sand is gaining prominence in foundry applications due to its superior bonding strength, reduced permeability, and enhanced surface finish compared to traditional uncoated sand, driving innovations in casting quality and efficiency. Emerging trends emphasize eco-friendly resin formulations and reclaimed sand technologies to minimize environmental impact and improve sustainability in foundry operations. The future outlook includes increased adoption of advanced resin-coated sands with improved thermal stability and recyclability, aligning with industry demands for higher precision and cost-effective production.

Resin-coated sand vs Uncoated sand Infographic

materialdif.com

materialdif.com