Natural sand is formed by the weathering and erosion of rocks over time, resulting in rounded and smooth particles ideal for construction. Crushed sand, produced by mechanically crushing rocks, has angular and rough-textured particles, providing better interlocking and strength in concrete mixes. Both types of sand have distinct advantages, with natural sand being preferred for its workability, while crushed sand is favored for its strength and durability in structural applications.

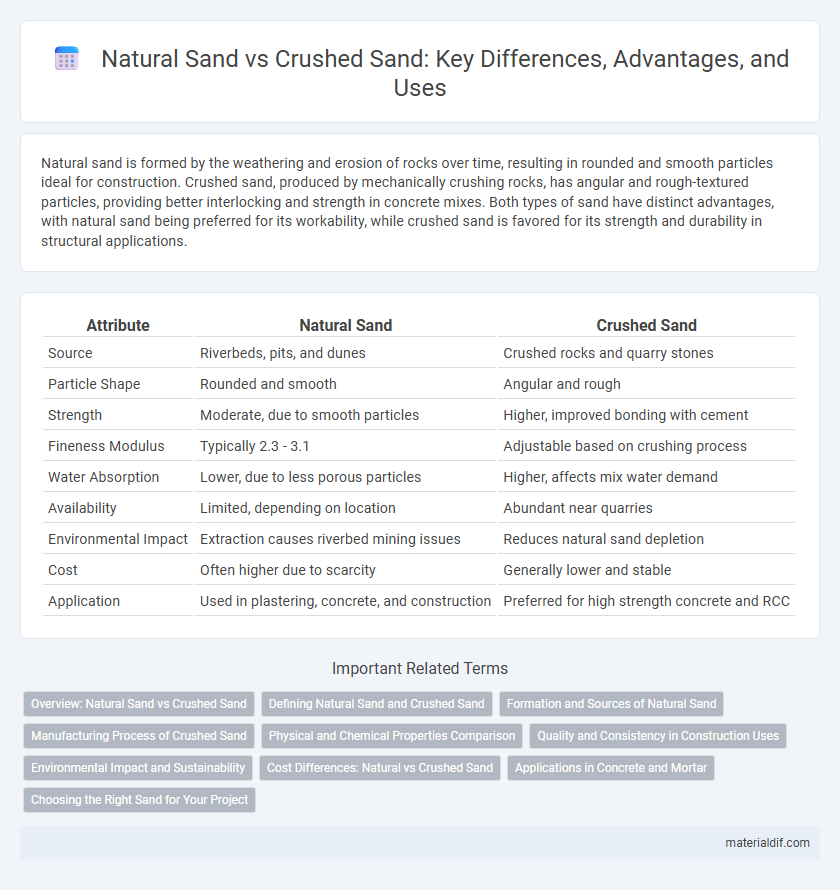

Table of Comparison

| Attribute | Natural Sand | Crushed Sand |

|---|---|---|

| Source | Riverbeds, pits, and dunes | Crushed rocks and quarry stones |

| Particle Shape | Rounded and smooth | Angular and rough |

| Strength | Moderate, due to smooth particles | Higher, improved bonding with cement |

| Fineness Modulus | Typically 2.3 - 3.1 | Adjustable based on crushing process |

| Water Absorption | Lower, due to less porous particles | Higher, affects mix water demand |

| Availability | Limited, depending on location | Abundant near quarries |

| Environmental Impact | Extraction causes riverbed mining issues | Reduces natural sand depletion |

| Cost | Often higher due to scarcity | Generally lower and stable |

| Application | Used in plastering, concrete, and construction | Preferred for high strength concrete and RCC |

Overview: Natural Sand vs Crushed Sand

Natural sand, typically sourced from riverbeds and lakes, consists of smooth, rounded particles formed through weathering and erosion, making it ideal for construction applications requiring high workability. Crushed sand, produced by mechanically crushing rocks, offers angular and rough particles that enhance bonding strength and durability in concrete mixtures. The choice between natural and crushed sand influences the texture, strength, and cost-effectiveness of construction materials.

Defining Natural Sand and Crushed Sand

Natural sand is derived from the weathering and erosion of rocks, typically found in riverbeds, beaches, and deserts, characterized by its rounded particles and natural composition. Crushed sand, also known as manufactured sand, is produced by mechanically crushing rocks, resulting in angular particles with a more consistent gradation and higher hardness. Both types of sand are essential in construction, with natural sand favored for its workability and crushed sand valued for its strength and durability in concrete mixtures.

Formation and Sources of Natural Sand

Natural sand forms through the gradual weathering and erosion of rocks over thousands of years, primarily sourced from riverbeds, beaches, and deserts. This type of sand consists of smooth, rounded particles originating from minerals like quartz and feldspar found in natural deposits. Its formation process results in a well-graded texture, making it suitable for construction and concrete applications.

Manufacturing Process of Crushed Sand

Crushed sand is manufactured by mechanically crushing rocks or stones, often granite or basalt, using jaw crushers, cone crushers, or impact crushers to produce fine, angular particles. The manufacturing process includes sorting, washing, and removing impurities to ensure the sand meets construction quality standards. This controlled production results in consistent particle size and shape, making crushed sand a reliable alternative to natural sand in concrete and masonry applications.

Physical and Chemical Properties Comparison

Natural sand primarily consists of smooth, rounded grains derived from weathered rock, exhibiting consistent particle size and lower angularity, which impacts concrete workability and strength. Crushed sand features angular, rough-textured particles with higher surface area, enhancing mechanical interlock but potentially increasing water demand and affecting durability. Chemically, natural sand is mostly composed of quartz and feldspar with minimal impurities, while crushed sand can contain varying mineral compositions and trace elements depending on the source rock, influencing alkali-silica reaction potential in concrete.

Quality and Consistency in Construction Uses

Natural sand offers superior grain shape and texture, providing excellent workability and bonding in concrete applications. Crushed sand, produced from mechanically crushed rocks, delivers more consistent particle size distribution and higher angularity, enhancing strength and durability in construction projects. Quality varies significantly with natural sand sources, whereas crushed sand ensures reliable performance through controlled production processes.

Environmental Impact and Sustainability

Natural sand extraction depletes riverbeds, causing erosion, habitat loss, and disruption of aquatic ecosystems, which significantly harms biodiversity. Crushed sand, sourced from quarry rocks, reduces the pressure on natural riverine environments but involves energy-intensive crushing processes that emit greenhouse gases. Sustainable practices emphasize recycled sand use and responsible quarry management to minimize ecological damage and promote long-term resource availability.

Cost Differences: Natural vs Crushed Sand

Natural sand generally incurs lower costs due to minimal processing and direct extraction from riverbeds or pits, making it more affordable for construction projects. Crushed sand involves additional crushing and screening processes, which elevate production expenses and transportation costs, resulting in higher prices. However, crushed sand often provides better quality and grading consistency, which can justify the increased investment for durable infrastructure.

Applications in Concrete and Mortar

Natural sand, composed of weathered rock particles, offers smooth texture ideal for concrete and mortar applications requiring workability and finish quality. Crushed sand, produced by mechanical crushing of rocks, provides angular and rough particles that enhance bond strength and durability in structural concrete and high-performance mortar mixes. Selection between natural and crushed sand impacts the compressive strength, water demand, and shrinkage behavior of concrete and mortar in construction projects.

Choosing the Right Sand for Your Project

Natural sand, sourced from riverbeds and beaches, offers smooth texture and consistent grain size ideal for plastering and finishing work. Crushed sand, produced by mechanically crushing rocks, provides angular particles that enhance concrete strength and bonding in structural projects. Selecting the right sand depends on the project requirements, with natural sand preferred for aesthetic finishes and crushed sand favored for durability and load-bearing applications.

Natural sand vs Crushed sand Infographic

materialdif.com

materialdif.com