Washed sand is free from impurities such as clay, silt, and dust, making it ideal for construction projects requiring strong concrete and mortar. Unwashed sand contains these fine particles, which can weaken the bonding strength and reduce the durability of the final structure. Choosing washed sand enhances the quality and longevity of building materials by ensuring better adhesion and reduced shrinkage.

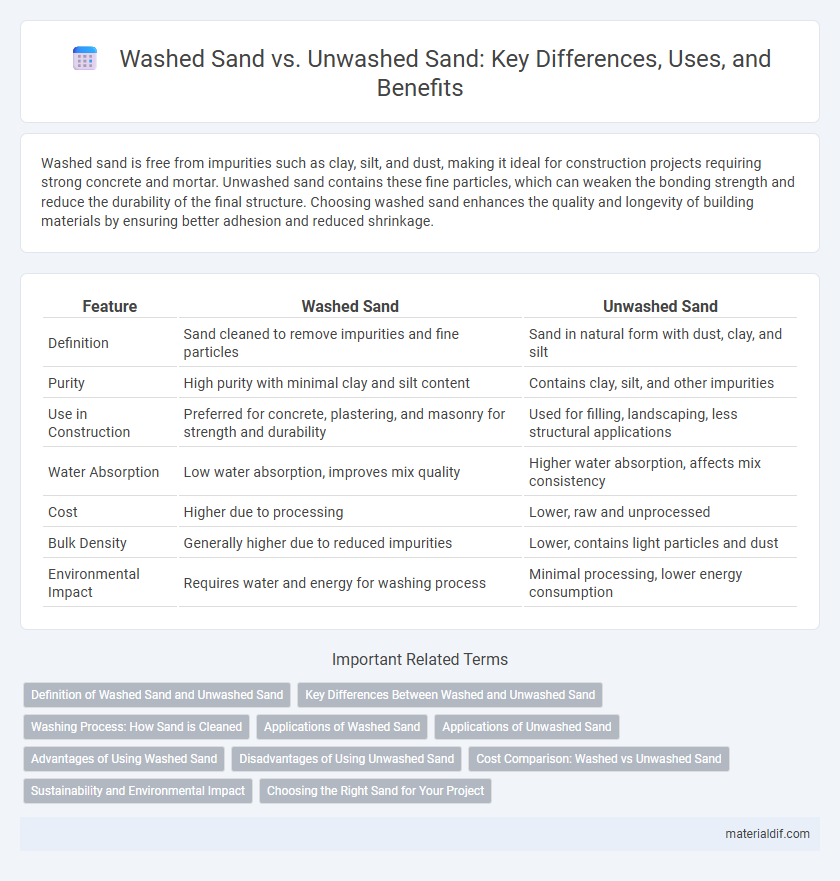

Table of Comparison

| Feature | Washed Sand | Unwashed Sand |

|---|---|---|

| Definition | Sand cleaned to remove impurities and fine particles | Sand in natural form with dust, clay, and silt |

| Purity | High purity with minimal clay and silt content | Contains clay, silt, and other impurities |

| Use in Construction | Preferred for concrete, plastering, and masonry for strength and durability | Used for filling, landscaping, less structural applications |

| Water Absorption | Low water absorption, improves mix quality | Higher water absorption, affects mix consistency |

| Cost | Higher due to processing | Lower, raw and unprocessed |

| Bulk Density | Generally higher due to reduced impurities | Lower, contains light particles and dust |

| Environmental Impact | Requires water and energy for washing process | Minimal processing, lower energy consumption |

Definition of Washed Sand and Unwashed Sand

Washed sand refers to sand that has been cleaned to remove impurities such as clay, silt, and dust, resulting in a higher purity and better quality material for construction purposes. Unwashed sand contains natural dirt, clay, and organic particles, which can affect the strength and durability of concrete and mortar. The choice between washed and unwashed sand impacts the final performance of building materials, with washed sand being preferred for high-strength applications.

Key Differences Between Washed and Unwashed Sand

Washed sand undergoes a thorough cleaning process to remove impurities such as silt, clay, and dust, resulting in higher purity and better drainage properties, making it ideal for concrete production and plastering. Unwashed sand contains natural fines and organic materials that can affect the strength and durability of construction projects, often used in landscaping or as a base material. The key difference lies in cleanliness and suitability, where washed sand provides improved bonding and structural integrity compared to the more contaminated unwashed variety.

Washing Process: How Sand is Cleaned

The washing process for sand involves removing impurities such as clay, silt, and organic matter by agitating the sand in water, often within a sand washer or a washing plant. Cleaned sand enhances strength and bonding properties in construction applications by ensuring finer particles and contaminants are thoroughly washed away. Washed sand undergoes multiple rinsing cycles, whereas unwashed sand retains dirt and debris, affecting its quality and usability.

Applications of Washed Sand

Washed sand is commonly used in construction projects requiring high-quality aggregates, such as concrete production, plastering, and bricklaying, due to its cleanliness and reduced impurity content. Its low levels of silt, clay, and dust improve the strength and durability of concrete and mortar mixtures, making it ideal for structural applications and finishing works. Landscaping and decorative purposes also benefit from washed sand's uniform texture and enhanced drainage properties.

Applications of Unwashed Sand

Unwashed sand is primarily used in construction applications such as concrete production, mortar mixing, and road base material where the presence of clay, silt, and organic matter does not significantly impact performance. It is also commonly employed in landscaping projects, backfilling, and drainage systems due to its coarse texture and cost-effectiveness. The unwashed sand's natural impurities can provide better bonding in masonry work, making it suitable for bricklaying and plastering in certain conditions.

Advantages of Using Washed Sand

Washed sand offers superior purity by removing clay, silt, and other impurities, enhancing its bonding strength in construction applications. Its higher cleanliness improves concrete durability and workability, reducing the risk of cracking and structural failure. Using washed sand also minimizes contamination in plastering and masonry, ensuring smoother finishes and better adhesion.

Disadvantages of Using Unwashed Sand

Unwashed sand contains impurities such as clay, silt, and organic matter, which reduce the strength and durability of concrete and mortar. These contaminants lead to poor bonding with cement, resulting in weaker construction and potential structural issues. Moreover, unwashed sand increases water demand in mixes, causing reduced workability and higher costs for water treatment.

Cost Comparison: Washed vs Unwashed Sand

Washed sand typically costs more than unwashed sand due to the additional labor and water required for cleaning impurities and fine particles. Unwashed sand is cheaper but may contain clay, silt, and organic matter, impacting durability and strength in construction. Choosing washed sand can reduce maintenance and increase the longevity of concrete structures, making it a cost-effective option despite the higher initial price.

Sustainability and Environmental Impact

Washed sand reduces impurities and fine particles, leading to better drainage and less environmental runoff, which supports sustainable construction practices by minimizing soil erosion and water contamination. Unwashed sand often contains silt and clay, causing increased water usage and potential blockage in drainage systems that harm local ecosystems. Choosing washed sand promotes resource efficiency and reduces the environmental impact associated with sediment pollution and waste management in construction projects.

Choosing the Right Sand for Your Project

Washed sand offers superior cleanliness by removing silt, clay, and impurities, making it ideal for concrete, plastering, and masonry projects where strength and durability are critical. Unwashed sand retains natural fines, providing better compaction and moisture retention, suitable for landscaping, gardening, and fill applications. Selecting the right sand depends on the project's requirements for purity, particle size, and application to ensure optimal performance and finish quality.

Washed sand vs Unwashed sand Infographic

materialdif.com

materialdif.com